This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 2872610 O-Ring Seal is a critical component for maintaining the integrity of seals within heavy-duty truck systems. It ensures operational efficiency and reliability by preventing leaks and ensuring proper system function, contributing to the overall performance and longevity of heavy-duty trucks.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a toroidal (ring-shaped) elastomer with a circular cross-section used to create seals in various mechanical systems. It operates by being compressed between two surfaces, forming a barrier that prevents the passage of fluids or gases. O-Rings are widely utilized due to their simplicity, effectiveness, and versatility in sealing applications 1.

Purpose of the 2872610 O-Ring Seal in Truck Operation

This Cummins part plays a specific role in the operation of heavy-duty trucks by ensuring the integrity of seals in various systems. It is applied in areas where fluid or gas containment is necessary, such as in engine components, fuel systems, and hydraulic systems. The seal supports these systems by maintaining pressure and preventing leaks, which is vital for the efficient operation of the truck 2.

Key Features of the 2872610 O-Ring Seal

The primary characteristics of the 2872610 O-Ring Seal include its material composition, dimensions, and design features. It is typically made from durable elastomers that offer resistance to a range of environmental factors. The seal’s dimensions are tailored to fit specific applications, ensuring a snug fit and effective sealing. Design features may include reinforced edges or specific durometer ratings to enhance performance and durability.

Benefits of Using the 2872610 O-Ring Seal

The advantages provided by this part include improved sealing efficiency, longevity, and resistance to various environmental factors. Its design allows for reliable performance under demanding conditions, reducing the risk of leaks and system failures. The seal’s durability ensures that it can withstand the rigors of heavy-duty truck operation, contributing to the vehicle’s overall reliability 3.

Installation and Maintenance Guidelines

Proper installation of the 2872610 O-Ring Seal involves ensuring that the mating surfaces are clean and free of debris. The seal should be lubricated before installation to facilitate seating and reduce the risk of damage. Regular maintenance includes inspecting the seal for signs of wear or damage and replacing it as necessary to ensure continued system integrity.

Troubleshooting Common Issues

Frequent problems associated with O-Ring Seals, such as leaks or wear, can often be traced to installation errors, environmental factors, or natural wear over time. Diagnosing these issues involves inspecting the seal and its mating surfaces for damage or misalignment. Resolving these issues may require replacing the seal, ensuring proper installation techniques are used, or addressing environmental factors that contribute to seal degradation.

Manufacturer Information - Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history of innovation and quality, Cummins has established a strong reputation in the heavy-duty truck industry. The company’s product range includes components and systems designed to enhance the performance, efficiency, and reliability of heavy-duty vehicles.

Cummins O-Ring Seal 2872610 Compatibility

The Cummins O-Ring Seal part number 2872610 is designed to fit a variety of Cummins engines, ensuring a secure seal in critical areas where leaks could otherwise occur. This part is integral to maintaining the integrity of the engine’s systems by preventing fluid or air leaks.

Engine Compatibility

6C8.3

The 6C8.3 engine benefits from the O-Ring Seal 2872610 in its sealing applications, ensuring that the engine operates efficiently and reliably.

ISL9 CM2150 SN and ISL9.5 CM2880 L138

Both the ISL9 CM2150 SN and ISL9.5 CM2880 L138 engines utilize the O-Ring Seal 2872610 in similar sealing contexts. This part is crucial for maintaining the performance and longevity of these engines by preventing leaks in high-pressure areas.

QSL9 CM850 (CM2850)

The QSL9 CM850 (CM2850) engine also incorporates the O-Ring Seal 2872610. This part is essential for ensuring that the engine’s sealing systems remain intact, which is vital for the engine’s overall performance and efficiency.

X15 CM2350 X116B

The X15 CM2350 X116B engine is another beneficiary of the O-Ring Seal 2872610. This part plays a critical role in maintaining the engine’s sealing integrity, which is crucial for preventing leaks and ensuring optimal engine operation.

By fitting these engines, the O-Ring Seal 2872610 ensures that the engines maintain their operational efficiency and reliability.

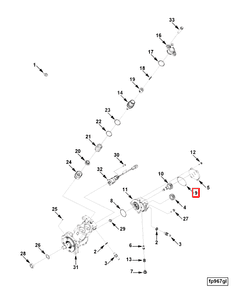

Role of Part 2872610 O-Ring Seal in Engine Systems

This part is instrumental in maintaining the integrity and efficiency of various engine components. In the Fuel Pump, the O-Ring Seal ensures a tight and leak-free connection between the pump and its housing, preventing fuel leakage and maintaining consistent fuel pressure.

Within the Fuel Pump Assembly, the O-Ring Seal plays a significant role in sealing the interfaces between different sub-components, ensuring that the assembly functions as a cohesive unit without any fuel loss.

For the Fuel Pump Body, the O-Ring Seal is essential in creating a secure seal around the pump’s inlet and outlet ports, which is vital for the pump’s operational efficiency and durability.

In the Fuel Pump Gear Housing, the O-Ring Seal is used to prevent any fuel from escaping through the gear housing, thus maintaining the proper lubrication and cooling of the gear components.

When it comes to the Fuel Pump Repair Kit, the inclusion of the O-Ring Seal is paramount. It allows for the restoration of seals that may have degraded over time, ensuring that the repaired fuel pump operates efficiently and reliably.

Lastly, in a Gear Fuel Pump system, the O-Ring Seal is utilized to ensure that the mechanical components within the pump are well-lubricated and that there is no fuel leakage, which could lead to inefficient operation or potential safety hazards.

Overall, the part 2872610 O-Ring Seal is a fundamental component in these engine systems, contributing to their reliability, efficiency, and safety.

Conclusion

The Cummins 2872610 O-Ring Seal is a vital component in the maintenance and operation of heavy-duty truck systems. Its role in preventing leaks, ensuring system integrity, and contributing to the overall performance and reliability of these vehicles cannot be overstated. Proper installation, maintenance, and understanding of its compatibility and application are essential for maximizing the benefits of this part.

-

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Bennett, Sean. Modern Diesel Technology: Light Duty Diesels. Cengage Learning, 2012.

↩ -

Hilgers, Michael. Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.