This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 2883845 O-Ring Seal is a critical component designed to maintain the integrity of seals in various systems within heavy-duty trucks. Its role is significant in ensuring the efficiency and reliability of these vehicles, particularly in environments where durability and performance are essential.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket made from a toroidal piece of elastomer with a round cross-section. It is widely used in automotive and industrial applications to create seals in dynamic and static applications. O-Rings function by being compressed between two or more mating surfaces, creating a seal that prevents the leakage of fluids or gases. Their versatility and effectiveness make them a common choice for sealing solutions across various industries 1.

Purpose of the Cummins 2883845 O-Ring Seal

The Cummins 2883845 O-Ring Seal is specifically engineered to play a role in the sealing mechanisms within heavy-duty trucks. It is applied in areas where fluid or gas containment is required, such as within the engine or other critical systems. By ensuring a tight seal, it helps maintain system pressure, prevent leaks, and protect sensitive components from contamination 2.

Key Features

The Cummins 2883845 O-Ring Seal is characterized by several key features that enhance its performance and longevity. These include its material composition, which is typically a durable elastomer designed to withstand the harsh conditions found in heavy-duty truck operations. The seal is also engineered to offer excellent temperature resistance, ensuring reliable performance across a wide range of operating conditions. Its design specifications are tailored to provide optimal sealing capabilities, contributing to the overall efficiency and reliability of the truck’s systems 3.

Benefits

Utilizing the Cummins 2883845 O-Ring Seal offers several advantages. It contributes to improved system efficiency by ensuring that fluids and gases are contained within their intended pathways. This reduces the risk of leaks, which can lead to system failures or inefficiencies. Additionally, the seal enhances the reliability of the truck’s systems, providing peace of mind to operators and maintenance personnel. Its contribution to overall engine performance is notable, as it helps maintain the integrity of critical seals, ensuring that the engine operates at peak efficiency 4.

Installation and Maintenance

Proper installation of the Cummins 2883845 O-Ring Seal is vital to ensure optimal performance. It should be installed in clean, dry conditions to prevent contamination that could compromise the seal. Regular maintenance, including inspections for wear or damage, is recommended to prolong the seal’s lifespan. Timely replacements should be performed according to the manufacturer’s guidelines or as part of routine maintenance schedules to ensure continued effective operation 5.

Troubleshooting Common Issues

Common problems associated with O-Ring Seals, such as leaks or failures, can often be traced back to installation errors, environmental factors, or wear and tear. Troubleshooting steps may include inspecting the seal for signs of damage, ensuring that mating surfaces are clean and free of debris, and verifying that the seal is correctly sized and installed. Regular inspections and timely replacements are emphasized to prevent issues from arising 6.

Manufacturer Information - Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, emissions solutions, and related technologies. With a strong reputation in the automotive industry, Cummins is committed to quality and innovation in manufacturing automotive components. Their products are designed to meet the demanding requirements of heavy-duty applications, ensuring reliability and performance in challenging environments 7.

Compatibility with Various Engines

The Cummins O-Ring Seal 2883845 is designed to fit seamlessly with a range of engines, ensuring a reliable seal to prevent leaks and maintain optimal engine performance. This O-Ring Seal is compatible with several engine models, including:

- ISV (Nissan)

- X12 CM2670 X121B

- X13 CM2670 X122B

- X15 CM2350 X116B

- Z14 CM2670 Z103B

For engines like the X12 CM2670 X121B and X13 CM2670 X122B, the O-Ring Seal 2883845 is engineered to fit precisely, ensuring a tight seal that prevents fluid leakage. These engines, while similar in some aspects, have specific requirements that this O-Ring Seal meets, making it an ideal choice for maintenance and repairs.

For the X15 CM2350 X116B engine, the O-Ring Seal 2883845 provides a critical seal that is essential for maintaining engine efficiency and preventing oil or fluid leaks. This engine, with its distinct specifications, benefits from the high-quality construction of the O-Ring Seal, ensuring longevity and reliability.

The Z14 CM2670 Z103B engine also integrates the O-Ring Seal 2883845 effectively. This seal is designed to withstand the operational demands of the Z14 engine, providing a dependable barrier against leaks and ensuring that the engine operates at peak performance.

Lastly, the ISV (Nissan) engine utilizes the O-Ring Seal 2883845 to maintain its operational integrity. This seal is crafted to fit the specific dimensions and requirements of the ISV engine, ensuring that it performs optimally and extends its service life.

By using the Cummins O-Ring Seal 2883845, technicians and engine owners can be confident that their engines will maintain a secure seal, preventing leaks and ensuring reliable performance across these various engine models 8.

Role of Part 2883845 O-Ring Seal in Engine Systems

The Cummins 2883845 O-Ring Seal is instrumental in maintaining the integrity and efficiency of various engine systems. In the context of a Fuel Pump, this O-Ring Seal ensures a tight and reliable seal between the pump housing and the pump body. This prevents any fuel leakage, which is essential for maintaining consistent fuel pressure and delivery to the engine.

When integrated with a general Pump system, the O-Ring Seal plays a similar role by ensuring that the pump operates within its designed parameters without any fluid loss. This is particularly important in high-pressure systems where even minor leaks can lead to significant performance issues.

In the Fuel System, the O-Ring Seal is used at various connection points to ensure that fuel lines and fittings remain sealed. This is vital for preventing fuel from escaping, which could lead to dangerous situations as well as inefficient fuel consumption.

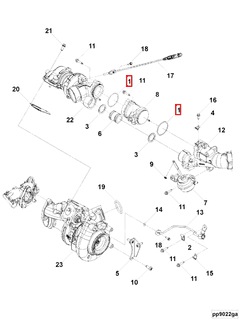

For the Turbocharger, the O-Ring Seal is often employed in the oil feed and return lines. These seals help maintain the necessary oil pressure for the turbocharger’s bearing system, ensuring smooth operation and longevity of the turbocharger.

In a Turbocharger Kit, which may include various ancillary components, the O-Ring Seal is used to ensure that all connections—whether they be for oil, air, or exhaust—remain sealed. This is important for the overall performance and reliability of the turbocharger system, as any leaks can lead to reduced efficiency and potential damage to the turbocharger 9.

Conclusion

The Cummins 2883845 O-Ring Seal plays a vital role in ensuring the efficiency, reliability, and performance of heavy-duty truck engines. Its compatibility with various engine models, coupled with its durable construction and temperature resistance, makes it an essential component for maintaining system integrity and preventing leaks. Proper installation, regular maintenance, and timely replacements are key to maximizing the benefits of this Cummins part.

-

Department of Energy Fundamentals Handbook, Department of Energy, 2015.

↩ -

Diesel Technology Fundamentals Service Repair Eighth Edition, Andrew Norman, The Goodheart-Willcox Company Inc, 2016.

↩ -

Fundamentals of Vehicle Dynamics, Thomas D. Gillespie, SAE International, 2021.

↩ -

Cummins Inc., Operation and Maintenance Manual, Bulletin Number 5504464, X11 CM2670 X126B.

↩ -

Cummins Inc., Operation and Maintenance Manual, Bulletin Number 5504464, X11 CM2670 X126B.

↩ -

Cummins Inc., Operation and Maintenance Manual, Bulletin Number 5504464, X11 CM2670 X126B.

↩ -

Cummins Inc., Operation and Maintenance Manual, Bulletin Number 5504464, X11 CM2670 X126B.

↩ -

Cummins Inc., Operation and Maintenance Manual, Bulletin Number 5504464, X11 CM2670 X126B.

↩ -

Cummins Inc., Operation and Maintenance Manual, Bulletin Number 5504464, X11 CM2670 X126B.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.