This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3002562 O-Ring Seal is a critical component designed to maintain the integrity of fluid systems within commercial trucks. It ensures reliable sealing between mating surfaces, preventing leaks and contributing to system efficiency and reliability.

Basic Concepts of O-Ring Seals

O-Ring Seals are elastomeric rings with a circular cross-section, used to create seals in dynamic and static applications. They function by being compressed between two surfaces, forming a barrier that prevents the passage of fluids and gases. Their simplicity, effectiveness, and versatility make them widely utilized in various mechanical systems 1.

Purpose of the Cummins 3002562 O-Ring Seal

This Cummins part ensures the sealing integrity of certain fluid systems in commercial trucks. It is crucial for components where fluid dynamics are critical, such as fuel systems, hydraulic systems, and cooling systems. By maintaining a tight seal, it helps preserve the efficiency and performance of these systems 2.

Key Features

The Cummins 3002562 O-Ring Seal is made from durable elastomers that offer resistance to a wide range of temperatures and chemical exposures. Its design specifications include precise dimensions to ensure a proper fit and effective sealing. Enhanced flexibility and compression set resistance contribute to its performance under varying operational conditions.

Benefits

Utilizing the Cummins 3002562 O-Ring Seal offers several advantages, including improved sealing efficiency, reduced risk of leaks, and maintained system pressure. Its durability ensures long-term performance under demanding conditions. Additionally, its resistance to environmental factors enhances its reliability in commercial truck applications 3.

Installation Considerations

Proper installation of the Cummins 3002562 O-Ring Seal is crucial for optimal performance and longevity. Guidelines include ensuring mating surfaces are clean, using correct installation tools to avoid damage, and verifying the O-Ring is properly seated without twists or folds.

Troubleshooting Common Issues

Common problems with O-Ring Seals include leaks, which can arise from improper installation, wear and tear, or exposure to incompatible fluids. Troubleshooting involves inspecting the O-Ring for damage, checking mating surfaces for cleanliness and condition, and ensuring the system operates within specified temperature and pressure parameters.

Maintenance Tips

Routine maintenance practices can prolong the life of the Cummins 3002562 O-Ring Seal and ensure continued reliable performance. These include regular inspections for wear or damage, cleaning the O-Ring and mating surfaces during maintenance intervals, and replacing the O-Ring as part of scheduled maintenance or when signs of degradation are observed.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry for producing reliable and efficient components.

Cummins O-Ring Seal 3002562 in V28 Engines

The O-Ring Seal 3002562, manufactured by Cummins, is a critical component in the V28 engine series. It provides a reliable barrier against leaks, ensuring the engine operates efficiently and safely. Its placement within the engine is crucial, often situated in areas where fluid or gas containment is essential.

In the V28 engine, the O-Ring Seal 3002562 is typically used in the following applications:

- Fuel Injection System: Ensuring that fuel does not leak from the injection points, maintaining the integrity of the fuel system.

- Oil Passages: Preventing oil leaks in critical areas, which helps in maintaining proper lubrication and engine performance.

- Exhaust Manifolds: Securing the exhaust manifold to prevent exhaust leaks, which can affect engine efficiency and emissions.

The O-Ring Seal 3002562’s design allows it to withstand high temperatures and pressures, making it suitable for the demanding conditions within the V28 engine. Its material composition ensures durability and resistance to various chemicals, which is essential for maintaining the engine’s longevity.

Proper installation of this seal is vital to prevent any potential failures that could lead to engine damage. Technicians should follow Cummins’ guidelines for installation, ensuring that the seal is correctly seated and not damaged during the process. Regular inspection and replacement of the O-Ring Seal 3002562 are recommended as part of routine maintenance to avoid unexpected breakdowns.

Role of Part 3002562 O-Ring Seal in Engine Systems

The part 3002562 O-Ring Seal is instrumental in maintaining the integrity and efficiency of various engine components. Its application spans across multiple areas, ensuring that each part functions optimally.

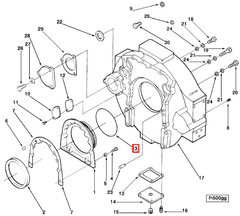

Flywheel Housing and Gear Box

In the flywheel housing and gear box, the O-Ring Seal plays a significant role in preventing leaks and maintaining pressure. It ensures that lubricants and other fluids remain contained within the system, which is essential for the smooth operation of these components. The seal’s placement around the housing and gear box interfaces helps in reducing friction and wear, contributing to the longevity of the parts.

Housing and Flywheel

When integrated into the housing and flywheel, the O-Ring Seal aids in creating a tight seal that prevents the ingress of contaminants. This is particularly important in high-stress environments where debris and dust can compromise the performance of the flywheel. The seal helps in maintaining a clean operating environment, which is vital for the precision required in flywheel operations.

Housing Flywheel and Overhaul Gasket Set

In conjunction with the housing flywheel and overhaul gasket set, the O-Ring Seal enhances the overall sealing effectiveness. During an overhaul, replacing or installing this seal ensures that the gasket set performs at its best. It helps in maintaining the structural integrity of the housing flywheel, which is critical for the engine’s balance and performance.

Rear Cover Plate and Shipping

The rear cover plate often requires a reliable seal to prevent fluid leakage, especially during shipping. The O-Ring Seal fitted in this area ensures that the cover plate remains secure and leak-free, protecting the internal components from external elements during transit. This is particularly important for engines that are transported over long distances or under varying environmental conditions.

Brackets

Brackets used in engine systems also benefit from the inclusion of the O-Ring Seal. These brackets often hold critical components in place and any leakage can lead to misalignment or failure. The seal ensures that any fluid used for lubrication or cooling within the bracket assembly is effectively contained, maintaining the structural and functional integrity of the brackets.

Conclusion

The Cummins 3002562 O-Ring Seal is a versatile component that enhances the performance and reliability of various engine systems by providing essential sealing functions across multiple applications. Its role in preventing leaks, maintaining system pressure, and ensuring the longevity of engine components underscores its importance in the maintenance and operation of commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.