This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3019960 Liner Seal Ring is a component designed for use in commercial truck engines. It serves a specific function within the engine’s cylinder assembly, contributing to the overall performance and reliability of the vehicle. Understanding its purpose and significance is important for maintaining the efficiency and longevity of truck engines.

Basic Concepts of Liner Seal Rings

Liner seal rings are components used in internal combustion engines to create a seal between the cylinder liner and the engine block. Their general function is to maintain compression within the cylinder, ensuring efficient combustion, and to prevent oil from leaking into the combustion chamber. This contributes to engine performance by maintaining optimal compression levels and reducing oil consumption, which in turn supports engine longevity by minimizing wear on other components 1.

Purpose of the 3019960 Liner Seal Ring

This Cummins part plays a role in the operation of a truck engine by maintaining compression within the cylinder. It ensures that the air-fuel mixture is compressed effectively before ignition, which is vital for efficient combustion. Additionally, it prevents oil from leaking into the combustion chamber, which could lead to contamination and reduced engine performance. By fulfilling these functions, the seal ring contributes to the engine’s overall efficiency and durability.

Key Features

The 3019960 Liner Seal Ring is characterized by its material composition, typically made from durable elastomers or composite materials that can withstand high temperatures and pressures. Its design specifications include precise dimensions to ensure a proper fit within the cylinder assembly. Unique attributes may include anti-extrusion features to prevent the seal from being forced out of its groove under pressure, enhancing its performance and durability.

Benefits

Using this part is associated with several benefits. It contributes to improved engine efficiency by maintaining optimal compression levels and preventing oil leakage. This results in reduced maintenance requirements, as the seal ring is designed to be durable and long-lasting. Additionally, the enhanced overall performance of the engine can lead to better fuel economy and reduced emissions, making it a valuable component for commercial truck operations 2.

Installation Process

Proper installation of the 3019960 Liner Seal Ring involves several steps to ensure optimal performance. It begins with cleaning the cylinder bore to remove any debris or old seal material. The seal ring should then be lubricated with clean engine oil before being carefully placed into the cylinder bore. Using a seal ring installer tool, the ring is pressed into its groove until it is fully seated. Care should be taken to avoid damaging the seal ring during installation. Following these steps ensures that the seal ring functions effectively within the engine.

Common Issues and Troubleshooting

Common issues with the 3019960 Liner Seal Ring may include leaks or wear over time. Leaks can often be identified by oil contamination in the combustion chamber or reduced engine performance. Wear may be detected during routine maintenance checks. Troubleshooting these issues involves inspecting the seal ring for signs of damage or improper seating. If necessary, the seal ring should be replaced to restore engine performance and prevent further complications.

Maintenance Tips

To prolong the lifespan of the 3019960 Liner Seal Ring, regular inspection intervals should be observed as part of the engine’s maintenance schedule. Cleaning procedures, such as using a compatible solvent to remove oil and debris from the cylinder bore, can help maintain the seal ring’s effectiveness. Additionally, following recommended replacement schedules based on engine hours or maintenance intervals can prevent unexpected failures and ensure continued engine performance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history dating back to 1919, Cummins has established a reputation for quality and reliability in the commercial truck industry. Its product offerings include a wide range of engines and components designed to meet the demanding requirements of commercial vehicles, contributing to the efficiency and performance of fleets worldwide 3.

Liner Seal Ring Component Usage

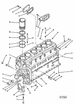

The Liner Seal Ring, part number 3019960, is a component in the assembly and operation of engine systems, particularly when integrated with a Shim Cylinder Liner Set.

When the Shim Cylinder Liner Set is installed, the Liner Seal Ring plays a role in ensuring the integrity of the cylinder’s internal environment. It is positioned to create a seal between the cylinder liner and the engine block, preventing any potential leaks of combustion gases or lubricants. This seal is vital for maintaining the pressure within the cylinder, which is necessary for efficient combustion and power generation.

Additionally, the Liner Seal Ring aids in the management of thermal expansion. As the engine operates, components expand due to heat. The seal ring accommodates this expansion, ensuring that the fit between the cylinder liner and the engine block remains tight and effective, thus preserving the engine’s performance and longevity.

Conclusion

In summary, the Liner Seal Ring, part 3019960, works in conjunction with the Shim Cylinder Liner Set to enhance the engine’s operational efficiency, reliability, and durability by providing a secure seal and accommodating thermal expansion.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.