This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

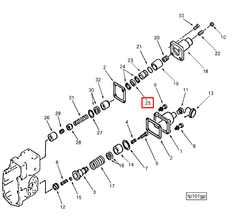

The Cummins 3026018 T Ring Seal is a specialized component designed to ensure the integrity of fluid systems in commercial trucks. Its role is to provide a reliable seal in various applications, contributing to the efficient operation of the vehicle. Understanding its purpose and significance is key to maintaining the performance and longevity of truck systems.

Basic Concepts of T Ring Seals

T Ring Seals are mechanical seals used to prevent leakage of fluids in rotating equipment. They consist of a sealing ring that fits into a groove and creates a barrier between the rotating and stationary parts of a system. These seals are commonly used in applications where high pressure and temperature are present, ensuring that fluids remain contained within the system 1.

Purpose of the Cummins 3026018 T Ring Seal

The Cummins 3026018 T Ring Seal plays a role in maintaining the integrity of fluid systems in trucks by providing a secure seal. It is specifically designed to fit into designated grooves, creating a barrier that prevents fluid leakage. This seal is important in applications where precise fluid control is necessary, such as in hydraulic systems, fuel lines, and other critical components of commercial trucks 2.

Key Features

The Cummins 3026018 T Ring Seal is characterized by its durable material composition, typically made from high-quality elastomers that offer resistance to wear and tear. Its design includes precise dimensions to ensure a snug fit within the designated grooves. Additionally, the seal may feature unique attributes such as anti-extrusion elements, which enhance its performance under high-pressure conditions 3.

Benefits

The Cummins 3026018 T Ring Seal offers several benefits, including improved sealing efficiency, which helps maintain system pressure and prevent fluid leaks. Its durability ensures long-term performance, even under demanding operating conditions. The seal’s resistance to various environmental factors, such as temperature fluctuations and chemical exposure, further contributes to its reliability.

Installation

Proper installation of the Cummins 3026018 T Ring Seal involves several steps to ensure optimal performance. Preparatory steps include cleaning the groove to remove any debris and ensuring the seal is free from damage. Using the appropriate tools, the seal should be carefully placed into the groove, ensuring it is seated correctly without distortion. Following manufacturer guidelines for torque and alignment is important during installation.

Troubleshooting

Common issues with T Ring Seals include wear, leakage, and failure due to improper installation or environmental factors. Diagnosing these problems involves inspecting the seal for signs of damage, such as cracks or deformation. Addressing these issues may require cleaning the groove, replacing the seal, or adjusting the system to reduce stress on the seal.

Maintenance

Regular maintenance of the Cummins 3026018 T Ring Seal is important to ensure continued performance. This includes periodic inspections for signs of wear or damage, cleaning the seal and groove to remove contaminants, and replacing the seal according to manufacturer recommendations or when signs of failure are detected.

Compatibility and Applications

The Cummins 3026018 T Ring Seal is designed for use in specific applications within commercial truck systems. It is compatible with various components and systems where fluid sealing is required. Understanding its applications and compatibility ensures that the seal is used effectively within the truck’s mechanical systems.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves commercial, industrial, and automotive markets. The company’s reputation in the commercial truck industry is built on its commitment to reliability, performance, and customer satisfaction.

Cummins T Ring Seal Part 3026018 Compatibility

The Cummins T Ring Seal part number 3026018 is designed to fit seamlessly with a range of Cummins engines, ensuring optimal performance and reliability. This seal is crucial for maintaining the integrity of the engine’s internal components by preventing leaks and ensuring proper sealing between rotating and stationary parts.

L10 MECHANICAL Engines

The L10 MECHANICAL engine series benefits from the precise fit and durability of the 3026018 T Ring Seal. This seal is engineered to withstand the high pressures and temperatures typical of these engines, ensuring longevity and consistent performance.

N14 MECHANICAL Engines

Similarly, the N14 MECHANICAL engines are well-suited for the 3026018 T Ring Seal. Given the robust nature of the N14 engines, this seal provides the necessary sealing integrity to maintain operational efficiency and reduce maintenance needs.

NH/NT 855 Engines

The NH/NT 855 engines also integrate the 3026018 T Ring Seal effectively. This seal is designed to fit the specific requirements of these engines, ensuring that they operate smoothly and efficiently. The precision of the seal helps in maintaining the engine’s performance and reliability over time.

Each of these engines, despite their different specifications and applications, relies on the 3026018 T Ring Seal to ensure that their sealing needs are met with the highest standards of quality and performance.

Role of Part 3026018 T Ring Seal in Engine Systems

The T Ring Seal, identified by part number 3026018, is an essential component in ensuring the efficient and reliable operation of various engine systems. Its primary function is to create a secure seal between moving or stationary parts, preventing leaks and maintaining system integrity.

Integration with Fuel Systems

In fuel-related components such as the Fuel Base Pump and Fuel Pump, the T Ring Seal plays a significant role. It ensures that fuel is delivered consistently without any leakage, which is vital for the pump’s performance and the overall fuel system’s efficiency. The seal is also used in the Fuel Injection system, where precise fuel delivery is necessary for optimal engine performance.

Application in Emissions Systems

The T Ring Seal is incorporated into the Emissions Rebuild Kit to maintain the integrity of the emissions control system. By sealing connections and joints, it helps in preventing the escape of harmful gases, ensuring that the system complies with environmental regulations.

Use in Road Speed and Governor Systems

In systems like the AFC-VS/Road Speed and Road Speed Governor, the T Ring Seal is used to ensure that all moving parts operate smoothly without fluid or air leaks. This is particularly important in maintaining the accuracy of speed control and governance mechanisms.

Fuel Pump Options and Codes

For components labeled as Fuel Pump Option and Fuel Pump Code, the T Ring Seal is utilized to enhance the reliability of these systems. It ensures that any variations or upgrades in the fuel pump design do not compromise the seal integrity, thus maintaining consistent fuel delivery.

General Pump Applications

Across various Pump applications, whether it’s a standard Pump, Fuel or a Pump, Fuel Base, the T Ring Seal is a common component. Its role in these systems is to ensure that the pump can operate under varying pressures without any risk of leakage, thereby prolonging the lifespan of the pump and enhancing its efficiency.

Conclusion

In summary, the T Ring Seal (part 3026018) is a versatile component that enhances the performance and reliability of multiple engine systems by providing essential sealing functions. Its integration into various critical systems underscores its importance in maintaining the operational efficiency and longevity of commercial truck engines.

-

Quansheng Zhan, Shengbo Eben, Li Kun Deng. Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning, 2018.

↩ -

Konrad Reif Ed. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Tigran Parikyan Ed. Advances in Engine and Powertrain Research and Technology. Springer Nature, 2022.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.