This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3026420 Dust Seal is a component designed to prevent contaminants from entering sensitive areas of heavy-duty trucks. Its role is significant in maintaining the integrity and performance of truck systems by ensuring that dust and debris do not interfere with the operation of critical components 3.

Basic Concepts of Dust Seals

Dust seals are components used in machinery to prevent the ingress of contaminants such as dust, dirt, and other particulates. They operate by creating a barrier between the external environment and the internal components of a system. Typically made from elastomeric materials, dust seals are designed to be flexible enough to conform to the surfaces they protect while maintaining a tight seal 4.

Purpose of the 3026420 Dust Seal in Truck Operation

The 3026420 Dust Seal plays a role in the operation of heavy-duty trucks by safeguarding various systems from environmental contaminants. It is commonly placed in areas where moving parts are exposed to the elements, such as around shafts and joints. By preventing the entry of dust and debris, the seal helps maintain the efficiency and longevity of these components 1.

Key Features of the 3026420 Dust Seal

The primary characteristics of the 3026420 Dust Seal include its material composition, which is typically a durable elastomer that offers flexibility and resistance to wear. The design elements of the seal may include specific lip configurations that enhance its ability to form a tight seal against rotating or reciprocating parts. Additionally, any unique attributes such as anti-extrusion features or reinforcement materials may be incorporated to improve performance under demanding conditions 2.

Benefits of Using the 3026420 Dust Seal

The advantages provided by the 3026420 Dust Seal include improved longevity of the components it protects, enhanced overall performance of the truck’s systems, and a reduction in maintenance requirements. By keeping contaminants out, the seal contributes to the smooth operation of machinery and helps prevent premature wear or failure of sensitive parts 3.

Installation and Maintenance Guidelines

Proper installation of the 3026420 Dust Seal involves ensuring that the seal is correctly aligned and seated within its housing without damage to the elastomer. It is important to follow manufacturer guidelines for torque settings and clearances to ensure the seal functions effectively. Maintenance tips include regular inspection for signs of wear or damage, and replacement as necessary to maintain the seal’s effectiveness 4.

Troubleshooting Common Issues

Typical problems associated with dust seals can include leaks, extrusion, or failure due to wear. Diagnosing these issues may involve visual inspection for physical damage or performance testing to identify leaks. Recommended solutions or repairs can range from simple replacement of the seal to more complex adjustments or repairs of the surrounding components if damage is extensive 1.

Manufacturer Information - Cummins

Cummins is a well-established manufacturer with a strong reputation in the industry for producing a wide range of products for heavy-duty trucks. With a history of innovation and quality, Cummins offers a comprehensive lineup of components designed to meet the rigorous demands of commercial vehicle applications 2.

Application in K38 and K50 Engines

The Dust Seal part 3026420 is specifically engineered to fit seamlessly within the K38 and K50 engine families. These engines are known for their robust design and reliability, often used in heavy-duty applications where exposure to harsh environments is common. The seal ensures that the internal components of these engines remain protected from external contaminants, thereby extending the engine’s lifespan and maintaining optimal performance 3.

Importance of the Dust Seal

In the context of the K38 and K50 engines, the Dust Seal part 3026420 plays a role in safeguarding the engine’s internal mechanisms. By effectively blocking out dust and debris, the seal helps to:

- Prevent Wear and Tear: Reduces the abrasive effects of contaminants on moving parts.

- Maintain Lubrication: Keeps the engine’s lubrication system clean, ensuring that oil and other fluids perform their intended functions.

- Enhance Efficiency: Ensures that the engine operates smoothly without the need for frequent maintenance due to contamination.

- Improve Reliability: Contributes to the overall reliability of the engine by minimizing the risk of damage from external elements 4.

Installation and Compatibility

The Dust Seal part 3026420 is designed for straightforward installation, ensuring that it fits snugly and securely within the specified engine models. Cummins has ensured that this seal is compatible with the K38 and K50 engines, making it a reliable choice for maintenance and repair 1.

Role of Part 3026420 Dust Seal in Engine Systems

The part 3026420 Dust Seal is a component in maintaining the integrity and performance of various engine systems. It is specifically designed to prevent the ingress of contaminants such as dust, dirt, and debris into sensitive engine components, thereby ensuring smooth operation and longevity 2.

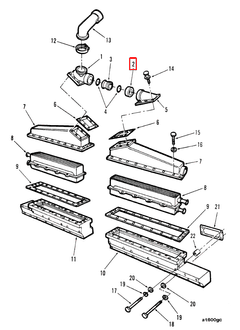

Air Inlet and Intake Connections

In the air inlet connection and air intake connection systems, the Dust Seal plays a role. It ensures that the air entering the engine is clean, which is vital for optimal combustion efficiency. By sealing these connections, it prevents external particles from mixing with the air-fuel mixture, which could otherwise lead to engine wear or decreased performance 3.

Air Intake Crossover and Manifold

When it comes to the air intake crossover and intake manifold, the Dust Seal helps maintain a consistent airflow. This is particularly important in high-performance engines where even minor disruptions in airflow can affect engine output. The seal ensures that the manifold operates under designed conditions, free from the interference of external contaminants 4.

Performance and Uprate Upper Set

In performance kits and uprate upper sets, the Dust Seal is often utilized to enhance the durability and reliability of these systems. These kits are designed to improve engine performance, and the inclusion of a Dust Seal ensures that the enhancements are not compromised by environmental factors. It allows the engine to operate at peak efficiency without the risk of contamination-induced failures 1.

Turbo T18A KV12 and PDC Kit

For turbocharged engines like the Turbo T18A KV12 and those utilizing a PDC (Performance Drivetrain Component) kit, the Dust Seal is equally important. Turbochargers are sensitive to contamination, and a breach in the sealing can lead to decreased turbo efficiency or even failure. The Dust Seal ensures that the turbo operates in a clean environment, thereby maximizing its lifespan and performance 2.

Manifold and Air Intake Systems

In manifold and air intake systems, the Dust Seal acts as a barrier against the entry of particulate matter. This is especially important in systems where the air intake is exposed to harsh environments, such as off-road or dusty conditions. The seal ensures that the intake system remains clean, which is essential for maintaining engine health and performance 3.

Conclusion

The Cummins 3026420 Dust Seal is a versatile component that enhances the functionality and reliability of various engine systems by providing a barrier against contaminants. Its application across different components underscores its importance in maintaining engine performance and longevity 4.

-

Van Gelder, Kirk T. Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning, 2018.

↩ ↩ ↩ ↩ -

Isermann, Rolf. Combustion Engine Diagnosis. Springer Vieweg, 2017.

↩ ↩ ↩ ↩ -

Giles, Tim. Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning, 2019.

↩ ↩ ↩ ↩ ↩ -

Duffy, Owen C, and Gus Wright. Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning, 2016.

↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.