This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

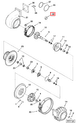

The Cummins 3029627 Dust Seal is a component designed to enhance the performance and longevity of heavy-duty trucks. Its purpose is to prevent contaminants such as dirt, dust, and debris from entering sensitive mechanical components, thereby maintaining the integrity and efficiency of the truck’s systems.

Basic Concepts of Dust Seals

Dust seals, also known as lip seals or exclusion seals, are mechanical components used to prevent the ingress of contaminants into moving parts. They function by creating a barrier between the external environment and the internal components of a system. Typically made from elastomeric materials, dust seals are designed to fit snugly around shafts or housings, providing a seal that can withstand various operational conditions. Their application is widespread in mechanical systems where protection against environmental contaminants is necessary 1.

Purpose of the 3029627 Dust Seal

The Cummins 3029627 Dust Seal plays a role in the operation of a truck by preventing contaminants from entering sensitive components. This seal is positioned in areas where shafts or rotating parts are exposed to the environment, such as in wheel hubs or transmission systems. By effectively blocking the entry of dirt and dust, the seal helps maintain the cleanliness of internal components, which is vital for the smooth operation and longevity of the truck 2.

Key Features

The Cummins 3029627 Dust Seal is characterized by its specific design and material properties that enhance its performance and durability. Constructed from high-quality elastomeric compounds, this seal offers excellent resistance to wear and tear. Its design includes a lip that contacts the shaft or housing, providing a tight seal that can adapt to minor misalignments and vibrations. Additionally, the material selection ensures compatibility with various lubricants and operating temperatures, making it suitable for demanding heavy-duty applications 3.

Benefits of Using the 3029627 Dust Seal

The advantages provided by the Cummins 3029627 Dust Seal include improved component longevity, reduced maintenance needs, and enhanced overall system efficiency. By keeping contaminants out, the seal helps prevent premature wear and damage to internal parts, leading to longer service intervals and reduced repair costs. Furthermore, the seal contributes to the efficient operation of the truck by ensuring that components remain clean and function as intended.

Installation Considerations

Proper installation of the Cummins 3029627 Dust Seal is vital to ensure optimal performance and longevity. Guidelines for installation include ensuring the sealing surface is clean and free of contaminants, using the correct tools to avoid damage to the seal, and verifying that the seal is properly seated and aligned. Following these best practices helps maintain the integrity of the seal and ensures it functions effectively throughout its service life.

Troubleshooting Common Issues

Common problems associated with dust seals include leaks, wear, and damage. Potential causes for these issues may include improper installation, exposure to harsh operating conditions, or the presence of contaminants that degrade the seal material. Recommended troubleshooting steps involve inspecting the seal for signs of wear or damage, checking the alignment and fit of the seal, and ensuring that the sealing surface is clean and free of contaminants. In cases where the seal is damaged or worn, replacement may be necessary to restore proper function.

Maintenance Tips

Maintaining the Cummins 3029627 Dust Seal involves regular inspection routines, cleaning procedures, and knowing when to consider replacement. Inspection should include checking for signs of wear, damage, or leaks. Cleaning the seal and its surrounding area can help remove contaminants that may affect its performance. Replacement should be considered if the seal shows significant wear, damage, or if leaks are present. Adhering to these maintenance practices helps ensure the continued effectiveness of the seal and the overall performance of the truck.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and aftermarket parts. With a history spanning over a century, Cummins is committed to quality, innovation, and customer satisfaction. The company’s product range includes engines for on-highway and off-highway applications, as well as components and systems that enhance the performance and efficiency of vehicles and equipment. Cummins’ dedication to excellence is evident in its rigorous testing and quality control processes, ensuring that its products meet the highest standards of reliability and performance.

Role of Part 3029627 Dust Seal in Engine Systems

The part 3029627 Dust Seal is an essential component in maintaining the integrity and performance of various engine systems. Its primary function is to prevent contaminants such as dust, dirt, and debris from entering sensitive areas of the engine, thereby ensuring smooth operation and longevity of the components.

In the context of an Air Inlet Connection, the Dust Seal acts as a barrier between the external environment and the internal components of the air intake system. This helps in maintaining the purity of the air entering the engine, which is vital for optimal combustion and efficiency.

When integrated into a Kit that includes multiple performance-enhancing parts, the Dust Seal contributes to the overall reliability of the system. It ensures that all components within the kit operate in a clean environment, free from abrasive particles that could cause wear and tear.

For the PDC (Powertrain Control Module), the Dust Seal is important in protecting electronic sensors and connectors from environmental contaminants. This protection is essential for accurate data collection and reliable performance of the powertrain system.

In Performance Parts, where every component is designed to maximize engine output, the Dust Seal plays a supportive yet significant role. It ensures that high-performance parts remain uncontaminated, allowing them to function at their peak without premature degradation.

The Turbocharger benefits greatly from the Dust Seal, as turbochargers are particularly sensitive to contaminants. By preventing dust and debris from entering the turbocharger, the Dust Seal helps maintain the efficiency and responsiveness of the turbo, leading to better overall engine performance.

In a Turbocharger Kit, which often includes various components designed to work in unison, the Dust Seal is a key element in ensuring that all parts of the kit remain clean and operational. This is especially important in high-stress environments where turbochargers are subjected to extreme conditions.

Lastly, in an Uprate Upper Set, which typically includes upgraded components for enhanced engine performance, the Dust Seal ensures that these premium parts are protected from environmental contaminants. This protection is vital for maintaining the performance gains achieved through the uprate, ensuring that the engine continues to operate at an elevated level.

Overall, the part 3029627 Dust Seal is a fundamental component in various engine systems, providing essential protection against contaminants and contributing to the reliability and performance of the engine.

Conclusion

The Cummins 3029627 Dust Seal is a critical component for maintaining the performance and longevity of heavy-duty trucks. By preventing contaminants from entering sensitive mechanical components, it ensures the smooth operation and efficiency of the truck’s systems. Proper installation, regular maintenance, and timely replacement are essential for maximizing the benefits of this Cummins part. Its role in various engine systems underscores its importance in protecting components from environmental contaminants, thereby contributing to the overall reliability and performance of the engine.

-

Hilgers, Michael. Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature, 2023.

↩ -

Wang, Yushu. Introduction to Engine Valvetrains. SAE International, 2007.

↩ -

Goodnight, Nicholas, and Kirk VanGelder. Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.