This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3036127 Hour Meter is a specialized device designed to monitor and record the operational hours of commercial truck engines. Its purpose is to provide accurate data on engine runtime, which is vital for effective maintenance scheduling and ensuring the longevity of the engine. This part is integral to the operation of commercial trucks, offering valuable insights into engine usage and facilitating informed decision-making regarding maintenance and repairs.

Basic Concepts of Hour Meters

An hour meter is a device that measures the operational time of machinery, such as engines. It functions by counting the number of hours the engine is running, providing a precise record of its usage. This data is crucial for tracking engine runtime, which is essential for maintenance planning. By monitoring the number of hours an engine operates, fleet managers can schedule maintenance tasks at optimal intervals, ensuring that the engine remains in peak condition and reducing the risk of unexpected breakdowns 1.

Purpose of the Cummins 3036127 Hour Meter

The Cummins 3036127 Hour Meter plays a significant role in the operation of a truck by accurately monitoring engine hours. This device aids in maintenance scheduling by providing precise data on engine runtime. With this information, fleet managers can plan maintenance tasks more effectively, ensuring that the engine is serviced at the appropriate intervals. This proactive approach to maintenance helps to extend the engine’s lifespan and maintain its performance 2.

Key Features

The Cummins 3036127 Hour Meter is characterized by several key features that enhance its functionality and reliability. These include high accuracy in recording engine hours, durability to withstand the harsh conditions of commercial truck operations, and ease of installation. Additionally, the meter may incorporate unique technological aspects, such as digital displays or connectivity options, that provide enhanced data collection and analysis capabilities.

Benefits of Using the Cummins 3036127 Hour Meter

Incorporating the Cummins 3036127 Hour Meter into truck operations offers several advantages. It improves maintenance planning by providing accurate data on engine runtime, allowing for more precise scheduling of maintenance tasks. This leads to enhanced engine longevity, as regular maintenance can prevent wear and tear. Furthermore, the meter contributes to increased operational efficiency by ensuring that the engine is always in optimal condition, reducing downtime and improving overall fleet performance.

Installation and Setup

Installing and setting up the Cummins 3036127 Hour Meter involves several steps. Begin by ensuring that the engine is turned off and the key is removed. Locate the appropriate mounting location on the truck’s dashboard or engine compartment. Using the provided mounting bracket and screws, secure the hour meter in place. Connect the wiring harness to the engine’s electrical system, following the manufacturer’s instructions. Finally, turn the engine on to verify that the hour meter is functioning correctly. It is important to use the necessary tools and take precautions to ensure a safe and proper installation.

Troubleshooting Common Issues

Common issues with the Cummins 3036127 Hour Meter may include inaccurate readings, display malfunctions, or connectivity problems. To troubleshoot these issues, first, ensure that the meter is securely mounted and that all connections are properly made. Check the wiring harness for any signs of damage or loose connections. If the display is malfunctioning, try resetting the meter by disconnecting and reconnecting the power source. For connectivity issues, verify that the meter is compatible with the fleet management system and that all software is up to date.

Maintenance Tips

To ensure the longevity and accuracy of the Cummins 3036127 Hour Meter, regular maintenance practices are recommended. Inspect the meter periodically for any signs of damage or wear. Clean the display and housing to remove dirt and debris that may affect its performance. Verify that all connections are secure and that the wiring harness is intact. Additionally, keep the meter’s software updated to ensure compatibility with the latest fleet management systems and to benefit from any improvements or bug fixes.

Integration with Fleet Management Systems

The Cummins 3036127 Hour Meter can be integrated with fleet management systems to enhance data collection and analysis. By connecting the meter to a fleet management system, operators can access real-time data on engine runtime, maintenance schedules, and performance metrics. This integration allows for more efficient monitoring of the fleet, enabling data-driven decisions that improve maintenance practices, reduce downtime, and enhance overall operational efficiency.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. Founded in 1919, Cummins has a long history of innovation and excellence in the commercial truck industry. The company is committed to providing reliable and efficient power solutions that meet the needs of its customers. Cummins’ expertise in engine technology and commitment to quality make it a trusted partner for commercial truck operators worldwide.

Cummins Engine Hour Meter Part 3036127

The Cummins engine part 3036127, an Hour Meter, is a crucial component designed to track the operational hours of various Cummins engines. This part is integral to maintaining the performance and reliability of the engines it is installed in. Here’s how it fits with the specified engines:

N14 CELECT and N14 CELECT PLUS

The N14 CELECT and N14 CELECT PLUS engines benefit from the precise tracking provided by the Hour Meter part 3036127. These engines, known for their robust performance, require accurate monitoring of operational hours to ensure timely maintenance and to maximize their lifespan. The Hour Meter ensures that the engine’s operational data is logged accurately, facilitating better maintenance planning and reducing unexpected downtime.

N14 MECHANICAL

For the N14 MECHANICAL engines, the Hour Meter part 3036127 plays a vital role in tracking engine hours. This engine variant, which relies on mechanical controls, needs reliable data to manage maintenance schedules effectively. The Hour Meter provides the necessary data to keep the engine running smoothly and to prevent wear and tear by scheduling maintenance at the right intervals.

NH/NT 855

The NH/NT 855 engines also integrate the Hour Meter part 3036127 to monitor operational hours. These engines are designed for heavy-duty applications, and accurate hour tracking is essential for maintaining their performance. The Hour Meter ensures that the engine’s operational data is recorded accurately, allowing for proactive maintenance and reducing the risk of unexpected failures.

V28

The V28 engine utilizes the Hour Meter part 3036127 to keep track of its operational hours. This engine, known for its versatility and reliability, requires precise monitoring to ensure optimal performance. The Hour Meter provides the necessary data to schedule maintenance and to keep the engine running efficiently, thereby extending its operational life.

By integrating the Hour Meter part 3036127, Cummins ensures that all these engines can be maintained effectively, leading to improved reliability and performance.

Role of Part 3036127 Hour Meter in Engine Systems

The Hour Meter (Part 3036127) is an essential component in monitoring the operational hours of various engine systems. It provides valuable data that aids in maintenance scheduling and performance evaluation. Here’s how it integrates with different engine components:

Integration with Engine Components

1. Bearing and Gasket Assemblies

The Hour Meter helps track the operational hours of Bearing/Gasket and Bearing Gasket Kit components. Regular monitoring allows for timely replacement of these parts, preventing potential failures and ensuring consistent engine performance.

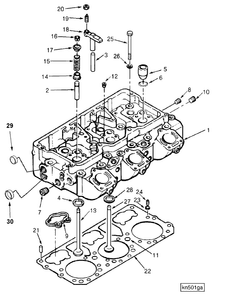

2. Camshaft and Cylinder Head

For components like the Camshaft and Cylinder Head, the Hour Meter is instrumental in determining when these parts may need inspection or replacement. This is particularly important for high-performance engines where precision and reliability are paramount.

3. Cylinder and Long Block Assemblies

In Cylinder and Long Block assemblies, the Hour Meter assists in tracking the usage hours, which is vital for planning overhauls and ensuring that the engine components are operating within their designed lifespan.

4. Dataplate and Performance Parts

The data recorded by the Hour Meter complements the information on the Dataplate, offering a comprehensive view of the engine’s operational history. For Performance Parts and EBM: Performance Parts, this data is invaluable for fine-tuning maintenance schedules and enhancing engine reliability.

5. Engine Gasket Sets and Overhaul Kits

Components such as the Engine Gasket Set Upper, Overhaul Gasket Set, and Engine Overhaul Kit benefit from the precise hour tracking provided by the Hour Meter. This ensures that gaskets and other critical components are replaced at optimal intervals, maintaining engine integrity.

6. Injector Plumbing and Lubricating Oil Cooler Mounting

For systems involving Injector Plumbing and Lubricating Oil Cooler Mounting, the Hour Meter helps in scheduling maintenance checks. This is essential for preventing leaks and ensuring efficient oil circulation, which is critical for engine health.

7. Turbocharger and Upper Engine Gasket Set

The Turbocharger and Upper Engine Gasket Set are components where the Hour Meter plays a significant role. By tracking the operational hours, mechanics can anticipate when these parts may require servicing or replacement, thus avoiding unexpected failures.

Conclusion

Incorporating the Hour Meter (Part 3036127) into engine systems provides a systematic approach to maintenance. It ensures that all components, from bearings and gaskets to turbochargers and performance parts, are maintained at optimal intervals, leading to enhanced engine performance and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.