3038058

O-Ring Seal

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3038058 O-Ring Seal is a component designed for use in commercial trucks. Its primary function is to provide a reliable seal in various applications within the truck’s systems, ensuring the integrity of fluid and gas pathways. This seal is integral to maintaining the efficiency and performance of the truck’s engine and other mechanical systems.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket made from a circular section of elastomer. It functions by being seated in a groove and compressed during assembly between two or more parts, creating a seal at the interface 1. O-Ring Seals are widely used in mechanical systems to prevent leakage of fluids and gases, and to protect against the ingress of contaminants. Their versatility and effectiveness make them a common component in various industries, including automotive and heavy-duty truck manufacturing.

Purpose of the 3038058 O-Ring Seal in Truck Operation

This Cummins part plays a specific role in the operation of a truck by ensuring the sealing of connections within the engine or other systems. It is designed to withstand the pressures and temperatures encountered in these environments, contributing to the overall efficiency and reliability of the truck’s performance. By maintaining a secure seal, it helps in preserving the integrity of the system’s fluid and gas pathways.

Key Features of the 3038058 O-Ring Seal

The 3038058 is characterized by its material composition, typically a durable elastomer that offers resistance to a range of environmental factors. Its dimensions are precisely engineered to fit specific applications, ensuring a snug fit in the designated grooves. The design of the seal includes features that enhance its ability to maintain a seal under pressure and temperature variations, contributing to its effectiveness in demanding applications.

Benefits of Using the 3038058 O-Ring Seal

Utilizing this part offers several advantages. Its design contributes to improved sealing performance, reducing the risk of leaks. The material’s durability ensures a longer service life, even under challenging conditions. Additionally, the seal’s resistance to various environmental factors, including chemicals and temperature extremes, enhances its reliability in commercial truck applications.

Installation and Maintenance

Proper installation of the 3038058 involves preparing the mating surfaces to ensure a clean and smooth fit. It is important to follow torque specifications during assembly to avoid over-tightening, which could damage the seal. Regular maintenance, including inspection for wear and damage, is recommended to ensure the longevity and optimal performance of the seal. Replacement should be considered if signs of degradation are observed.

Troubleshooting Common Issues

Common issues with O-Ring Seals, such as leaks or failures, can often be traced back to installation errors, environmental factors, or wear and tear. Troubleshooting steps include inspecting the seal and mating surfaces for damage, ensuring proper installation techniques were followed, and considering environmental conditions that may affect the seal’s performance. Addressing these issues promptly can help maintain the efficiency and reliability of the truck’s systems.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and technological advancements contribute to its leadership position in the market.

Role of Part 3038058 O-Ring Seal in Engine Systems

The 3038058 is instrumental in maintaining the integrity and efficiency of various engine systems. Its application ensures that fluid dynamics within the engine are optimized, preventing leaks and ensuring smooth operation.

Filter Systems

In filter systems, the O-Ring Seal is positioned to create a tight seal around the filter housing. This prevents contaminants from bypassing the filter media, ensuring that only clean fluid circulates through the engine. The seal’s resilience to varying temperatures and pressures is vital for consistent performance.

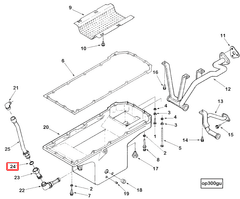

Lubricating Oil Systems

Within lubricating oil systems, the O-Ring Seal is employed at connection points such as the oil pan gasket and oil filter adapter. It ensures that lubricating oil is effectively contained, reducing the risk of oil starvation which could lead to increased friction and wear on engine components.

Lubricating Oil Bypass Tube and Hose

For the lubricating oil bypass tube and oil bypass hose, the O-Ring Seal plays a significant role in maintaining the bypass system’s functionality. It ensures that oil flows smoothly through the bypass when the filter becomes clogged, preventing excessive pressure build-up and potential damage to the filter or other components.

Oil Cooler

In oil cooler applications, the O-Ring Seal is used at the connections between the cooler and the associated piping. This seal is essential for maintaining the efficiency of the cooling process, ensuring that oil is adequately cooled before re-entering the engine, thus prolonging the life of engine components.

Turbocharger

The turbocharger relies on the O-Ring Seal at various connection points, including the oil feed and return lines. This ensures that lubricating oil reaches the turbocharger bearings without leakage, which is essential for the turbocharger’s operation and longevity.

Conclusion

In summary, the 3038058 is a fundamental component in ensuring the reliability and performance of engine systems by providing essential seals at critical connection points. Its role in maintaining the integrity of fluid and gas pathways within the engine is crucial for the overall efficiency and longevity of the truck’s mechanical systems.

-

Saiful Bari, Diesel Engine Combustion, Emissions and Condition Monitoring, InTech, 2013.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.