3051980

Rectangular Ring Seal

Cummins®

AVAILABLE

4 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Rectangular Ring Seal, Part #3051980, manufactured by Cummins, is a critical component in commercial truck operations. Cummins, a renowned name in the automotive industry, produces a wide range of parts and systems that enhance the efficiency and reliability of commercial vehicles. This part is essential for maintaining the integrity of various truck systems by providing effective sealing solutions.

Basic Concepts of Rectangular Ring Seals

A Rectangular Ring Seal is a type of gasket designed to create a seal between two or more mating surfaces. Constructed from materials that can withstand pressure, temperature, and chemical exposure, the seal deforms slightly when compressed, creating a barrier that prevents the leakage of fluids or gases. This type of seal is commonly used in applications requiring a reliable and durable seal.

Purpose of the 3051980 Rectangular Ring Seal in Truck Operations

The 3051980 Rectangular Ring Seal plays a role in the operation of commercial trucks by ensuring the integrity of seals in various systems. It is applied in systems where the prevention of leaks is necessary to maintain performance and safety. This includes applications in engine components, transmission systems, and hydraulic systems, where the seal helps to maintain pressure and prevent contamination 1.

Key Features of the 3051980 Rectangular Ring Seal

The design and material characteristics of the 3051980 Rectangular Ring Seal contribute to its effectiveness and durability. It is made from materials that offer resistance to wear, chemical exposure, and temperature variations. The seal’s rectangular shape allows it to fit into specific applications where other seal types may not be suitable. Additionally, the seal is engineered to provide a consistent sealing surface under compression, ensuring reliable performance over time 2.

Benefits of Using the 3051980 Rectangular Ring Seal

The 3051980 Rectangular Ring Seal offers several advantages. It provides improved sealing performance due to its design and material properties. The seal’s durability allows for longer service intervals between replacements, reducing maintenance costs. It also exhibits resistance to various operating conditions, including high pressure and temperature fluctuations, which are common in commercial truck environments 3.

Installation Considerations

Proper installation of the 3051980 Rectangular Ring Seal is important to ensure optimal performance and longevity. Guidelines for installation include ensuring that the mating surfaces are clean and free of debris, using the correct torque specifications when tightening components, and verifying that the seal is properly seated. Following these best practices helps to prevent installation-related issues that could affect the seal’s performance 4.

Common Issues and Troubleshooting

Typical problems associated with Rectangular Ring Seals include signs of wear, leakage, and failure. These issues can arise from improper installation, exposure to harsh operating conditions, or natural wear over time. Troubleshooting steps may involve inspecting the seal for damage, checking the mating surfaces for cleanliness and condition, and ensuring that the system is operating within specified parameters.

Maintenance Tips

Routine maintenance practices can help prolong the life of the 3051980 Rectangular Ring Seal. This includes regular inspection intervals to check for signs of wear or damage, and following manufacturer guidelines for replacement. Keeping the seal and its mating surfaces clean and free of contaminants also contributes to the seal’s longevity and performance.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial vehicle industry. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial applications.

Compatibility of 3051980 Rectangular Ring Seal

This Cummins part is designed to fit seamlessly with a variety of engine models, ensuring optimal performance and durability. It is compatible with the following engines:

- ISM CM570

- ISM11 CM876 SN

- ISX CM570

- ISX CM870

- ISX CM871

- ISX15 CM2250

- ISX15 CM2250 SN

- ISX15 CM2350 X101

- L10 MECHANICAL

- N14 MECHANICAL

- QSX15 CM2250 ECF

- QSX15 CM2350 X105

- X15 CM2350 X116B

- X15 CM2350 X123B

- X15 CM2450 X134B

This seal is engineered to provide a tight fit, preventing leaks and maintaining the integrity of the engine’s internal components. Its design ensures compatibility across different engine series, making it a versatile choice for maintenance and repair.

Role of 3051980 Rectangular Ring Seal in Engine Systems

The 3051980 Rectangular Ring Seal is integral to maintaining the integrity and efficiency of various engine components. It is strategically placed in areas where sealing is necessary to prevent leaks and ensure optimal performance.

Flywheel Housing

In the flywheel housing, the Rectangular Ring Seal ensures that no fluids or gases escape, which is vital for maintaining the pressure and efficiency of the system. This seal helps in keeping the flywheel securely in place and operating smoothly.

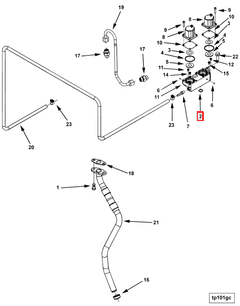

Fuel Bypass Tube

For the fuel bypass tube, the Rectangular Ring Seal plays a role in maintaining the fuel’s path without any leakage. This is essential for the consistent delivery of fuel to the engine, ensuring that the combustion process is efficient and reliable.

Fuel Pump and Housing

When installed in the fuel pump and its housing, the seal prevents any fuel from leaking out, which is important for maintaining the pressure within the fuel system. This ensures that the fuel pump can deliver the required amount of fuel to the engine under various operating conditions.

Pace Module Mounting

In the pace module mounting, the Rectangular Ring Seal ensures that the module is securely attached and that there are no gaps through which fluids or gases could escape. This is important for the accurate functioning of the pace module, which controls the timing of fuel injection.

Plumbing and Turbocharger

For the plumbing connected to the turbocharger, the seal is used to maintain the integrity of the system by preventing any leaks. This is particularly important in high-pressure environments where even small leaks can lead to significant performance issues.

Fuel Injection System

In the fuel injection system, the Rectangular Ring Seal ensures that the fuel is delivered precisely and without any leaks. This is essential for the efficient operation of the engine, as it directly impacts the combustion process.

Pump and Fuel System

Within the pump and broader fuel system, the seal helps in maintaining the necessary pressure and preventing any fuel from escaping. This ensures that the pump can operate efficiently and that the fuel system as a whole remains reliable.

By effectively sealing these various components, the Rectangular Ring Seal contributes to the overall performance and reliability of the engine system.

Conclusion

The 3051980 Rectangular Ring Seal by Cummins is a vital component in the maintenance and operation of commercial trucks. Its design and material properties ensure reliable sealing performance across various engine systems, contributing to the efficiency and safety of truck operations. Proper installation, regular maintenance, and understanding its role in different engine components are key to maximizing the benefits of this part.

-

Handbook of Diesel Engines, Klaus Mollenhauer and Helmut Tschoeke, Springer, 2010

↩ -

Diesel Emissions and Their Control: Second Edition, Addy Majewski and Hannu Jaskelainen, SAE International, 2023

↩ -

SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety, R. Matthew Brach, SAE International, 2023

↩ -

Motor Vehicle Mechanics Textbook, Fifth Edition, F. K. Sully, Heinemann Professional Publishing, 1998

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.