3066938

O-Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3066938 O-Ring Seal is a component designed to ensure the integrity of seals in heavy-duty truck systems. Its role is significant in maintaining the efficiency and reliability of these vehicles. Understanding its purpose and function is key to effective heavy-duty truck maintenance and operation.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket that forms a seal by being compressed within a groove. It operates by creating a barrier that prevents the leakage of fluids and gases in mechanical systems. O-Ring Seals are widely used due to their simplicity, effectiveness, and versatility in various applications 1.

Purpose of the Cummins 3066938 O-Ring Seal

This Cummins part is specifically designed to play a role in the sealing mechanisms of heavy-duty trucks. It is utilized in various systems where fluid and gas containment is necessary. This includes applications in engine components, fuel systems, and hydraulic systems, where it helps maintain system pressure and prevent leaks.

Key Features

This part is characterized by its material composition, typically made from durable elastomers that offer resistance to a range of operating conditions. Its design is tailored to fit specific grooves, ensuring a snug fit that enhances its sealing capabilities. The seal’s durability is a result of its material properties and design, which are engineered to withstand the rigors of heavy-duty truck operation.

Benefits

The use of the Cummins 3066938 O-Ring Seal offers several advantages. It contributes to improved system efficiency by ensuring that fluids and gases remain contained within their intended pathways. This reduces the risk of leaks, which can lead to system failures or inefficiencies. Additionally, the seal’s reliable performance helps in enhancing the longevity of connected components by protecting them from exposure to contaminants or excessive wear.

Installation Considerations

Proper installation of this part is vital for its performance and longevity. It should be installed in a clean, undamaged groove to ensure a proper fit. Care should be taken to avoid damaging the seal during installation, as this can compromise its sealing capabilities. Following manufacturer guidelines for torque and alignment is recommended to ensure optimal performance.

Troubleshooting Common Issues

Common issues with O-Ring Seals include leaks or failures, which can often be traced back to improper installation, damage, or degradation over time. Troubleshooting these issues involves inspecting the seal and its groove for signs of wear or damage, ensuring proper installation techniques are used, and replacing the seal if necessary to restore system integrity.

Maintenance Tips

Regular maintenance of the Cummins 3066938 O-Ring Seal involves periodic inspection for signs of wear or damage. Cleaning the seal and its groove can prevent contamination that may lead to seal failure. Replacement guidelines should be followed to ensure that the seal is changed before it reaches the end of its service life, maintaining system efficiency and reliability.

Compatibility with Cummins Engines

The O-Ring Seal part number 3066938, manufactured by Cummins, is designed to fit a variety of Cummins engines. This seal is crucial for ensuring that the engine operates efficiently by preventing leaks and maintaining the integrity of the system. Below is a detailed description of the compatibility of this seal with various Cummins engines.

K-Series Engines

- K38

- K50

KTA19 Engines

- KTA19GC

- KTA19GC CM558

L-Series Engines

- L10 MECHANICAL

N-Series Engines

- N14 MECHANICAL

QSK19 Engines

- QSK19 CM500

- QSK19 CM850 MCRS

- QSK19G

QSK38 Engines

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

QSK50 Engines

- QSK50 CM2150 K107

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

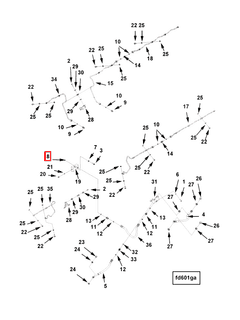

Role of Part 3066938 O-Ring Seal in Engine Systems

This part is integral to maintaining the integrity and efficiency of various engine systems. Its application spans across multiple components, ensuring that each system operates within optimal parameters.

Fuel System Integration

In the fuel block and fuel block mounting, the O-Ring Seal prevents fuel leaks, ensuring a consistent fuel supply to the engine. It is also essential in the fuel plumbing system, where it seals connections between the fuel pump and the fuel supply lines. This seal is vital for maintaining pressure and preventing fuel from escaping, which could lead to performance issues or safety hazards.

Lubrication System

Within the lubricating oil filter and lubricating oil filter head, the O-Ring Seal ensures that oil flows smoothly without any leaks. This is important for the full flow oil system, where consistent oil pressure is necessary to lubricate moving parts and reduce wear.

Housing and Gasket Applications

The O-Ring Seal is used in various housing components, such as the gear housing and valve housing, to create a tight seal that prevents fluid leakage. In conjunction with the gasket kit and lower engine gasket set, it enhances the overall sealing efficiency of the engine.

Plumbing and Couplings

For the service coupling 2008 assembly and service coupling 2009 assembly, the O-Ring Seal ensures that connections remain secure and leak-free. This is particularly important in the fuel drain and fuel supply systems, where any leakage could result in inefficient engine performance or contamination of the fuel.

Additional Components

The O-Ring Seal also plays a role in the bypass valve lever kit, pace module, and short block kit. In these applications, it ensures that all moving parts are properly sealed, contributing to the overall reliability and performance of the engine.

Drain and Lower Engine Applications

In the location drain and components of the lower engine o’ring set, the seal is used to prevent fluid leakage from critical areas, ensuring that the lower engine components remain clean and functional.

Check Valves and Mounting

Finally, in check valves and various mounting applications, the O-Ring Seal ensures that these components remain securely in place and function as intended, contributing to the engine’s overall efficiency and longevity.

Conclusion

The Cummins 3066938 O-Ring Seal plays a critical role in the maintenance and operation of heavy-duty truck engines. Its proper installation, maintenance, and understanding of its applications are essential for ensuring the efficiency and reliability of these vehicles. By preventing leaks and maintaining system integrity, this part contributes significantly to the overall performance and longevity of heavy-duty engines.

-

Crolla, David. Crolla Encyclopedia. Wiley, 2015.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.