This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3073960 O-Ring Seal is a critical component designed to maintain the integrity of seals in various systems within heavy-duty trucks. Its role is essential in ensuring the efficiency and reliability of truck operations, especially in environments where durability and performance are crucial.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket with a circular cross-section, used to create a seal between two or more parts. It operates by being compressed within a groove, forming a barrier that prevents the leakage of fluids or gases. O-Ring Seals are widely utilized in mechanical systems due to their simplicity, effectiveness, and versatility in various applications 1.

Purpose of the 3073960 O-Ring Seal in Truck Operation

The 3073960 O-Ring Seal plays a specific role in the operation of heavy-duty trucks by ensuring the sealing integrity in systems where fluid or gas containment is required. It is applied in areas such as fuel systems, hydraulic systems, and engine components, supporting the overall functionality and efficiency of these systems 2.

Key Features

The Cummins 3073960 O-Ring Seal is characterized by its material composition, typically made from durable elastomers that can withstand high temperatures and pressures. Its design is tailored to fit precisely within specified grooves, ensuring a tight seal. These features make it particularly suitable for the demanding conditions encountered in heavy-duty truck applications 3.

Benefits of Using the 3073960 O-Ring Seal

Utilizing the 3073960 O-Ring Seal offers several advantages, including enhanced system efficiency through reliable sealing, increased longevity due to its durable material, and improved reliability even under challenging operating conditions. These benefits contribute to the overall performance and maintenance efficiency of heavy-duty trucks 4.

Installation Considerations

Proper installation of the 3073960 O-Ring Seal is crucial for its performance and longevity. Guidelines recommend ensuring the groove is clean and free of debris before installation, using lubricants compatible with the O-Ring material to facilitate seating, and avoiding over-compression which can lead to seal failure 5.

Troubleshooting Common Issues

Common issues with O-Ring Seals, such as leaks or failures, can often be traced back to installation errors, material incompatibilities, or environmental factors. Troubleshooting steps include inspecting the seal and groove for damage, ensuring correct material selection, and addressing any environmental factors that may affect seal performance 6.

Maintenance Tips

Regular maintenance of the 3073960 O-Ring Seal involves periodic inspections for signs of wear or damage, cleaning the seal and groove to remove contaminants, and replacing the seal according to manufacturer guidelines or when signs of degradation are observed. These practices help prolong the service life of the seal and maintain system integrity 7.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related components. With a history of innovation and a strong reputation in the automotive and heavy-duty truck industry, Cummins is recognized for its commitment to quality, performance, and customer satisfaction.

O-Ring Seal Part 3073960 Compatibility with Cummins Engines

The O-Ring Seal part 3073960, manufactured by Cummins, is designed to fit seamlessly with several of their engine models. This seal is crucial for maintaining the integrity of various engine components by preventing leaks and ensuring a tight seal where necessary.

QSK50 CM2350 K108 and QSK95 CM2350 K111 Engines

The O-Ring Seal part 3073960 is compatible with both the QSK50 CM2350 K108 and QSK95 CM2350 K111 engines. These engines are part of Cummins’ robust lineup, known for their reliability and performance in demanding applications. The seal fits into specific areas of these engines, ensuring that critical components remain sealed and operational.

QSK95 CM2350 K113 Engine

Similarly, the QSK95 CM2350 K113 engine also accommodates the O-Ring Seal part 3073960. This engine shares many components with the QSK95 CM2350 K111, making the seal a versatile fit across these models. The seal’s role in this engine is equally important, providing essential sealing where it is needed to maintain engine efficiency and longevity.

By ensuring a proper fit and function, the O-Ring Seal part 3073960 contributes to the overall performance and durability of these Cummins engines.

Role of Part 3073960 O-Ring Seal in Engine Systems

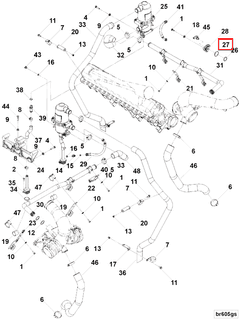

The Part 3073960 O-Ring Seal is instrumental in ensuring the integrity and efficiency of various engine systems by providing reliable sealing solutions. Here’s how it integrates with different components:

Adapter Connection

In the adapter connection, the O-Ring Seal ensures a tight seal between mating surfaces, preventing leaks of fluids such as oil or coolant. This is essential for maintaining system pressure and ensuring that the adapter functions correctly within the engine system.

Arrangement

When used in an arrangement involving multiple components, the O-Ring Seal helps in maintaining the structural integrity of the assembly. It ensures that each part fits snugly together, reducing the risk of misalignment and subsequent wear or failure.

Crankcase Breather

For the crankcase breather system, the O-Ring Seal is positioned to prevent the escape of crankcase gases. This helps in maintaining the proper pressure within the crankcase, which is vital for the efficient operation of the engine.

Connection

In various connection points throughout the engine, the O-Ring Seal plays a key role in sealing fluid passages. Whether it’s between the engine block and an external component or within the engine itself, the seal ensures that fluids remain contained within their designated pathways.

Water Inlet

At the water inlet, the O-Ring Seal is critical for preventing coolant leaks. This ensures that the cooling system operates efficiently, maintaining optimal engine temperature and preventing overheating.

Gasket Kit

When included in a gasket kit, the O-Ring Seal complements other gaskets by providing additional sealing at specific points where standard gaskets may not fit perfectly. This enhances the overall sealing effectiveness of the kit.

Oil Cooler Mounting

In the oil cooler mounting system, the O-Ring Seal ensures that the connection between the oil cooler and the engine is leak-free. This is important for maintaining the efficiency of the oil cooling process, which is essential for engine longevity.

Parts

In the broader context of engine parts, the O-Ring Seal is often used in conjunction with other components to ensure that assemblies, such as sensors or housings, are securely sealed. This prevents contaminants from entering sensitive areas and ensures that fluids remain where they are needed.

Base

At the base of various engine components, the O-Ring Seal helps in creating a secure seal between the base and other attached parts. This is particularly important in applications where vibration or movement could otherwise lead to leaks.

Overall, the Part 3073960 O-Ring Seal is a versatile component that enhances the reliability and performance of engine systems by providing essential sealing functions across a variety of applications.

Conclusion

The Cummins 3073960 O-Ring Seal is a vital component in the maintenance and operation of heavy-duty trucks and engines. Its role in ensuring the integrity of seals across various systems cannot be overstated. Proper installation, maintenance, and understanding of its compatibility with Cummins engines are key to maximizing its benefits and ensuring the longevity and efficiency of truck and engine operations.

-

Reif, K. (Ed.). (2014). Diesel Engine Management Systems and Components. Springer Vieweg.

↩ -

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ -

Eret, A. (2024). Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature.

↩ -

Bari, S. (2013). Diesel Engine Combustion, Emissions and Condition Monitoring. InTech.

↩ -

Cummins Inc. (n.d.). Service Manual (5579522).

↩ -

Cummins Inc. (n.d.). Service Manual (5579522).

↩ -

Cummins Inc. (n.d.). Service Manual (5579522).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.