3076102

O-Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

Minimum Quantity 8

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3076102 O-Ring Seal is a component designed to ensure the integrity of fluid systems within commercial trucks. Its role is to create a reliable seal in various applications, contributing to the efficient operation of the vehicle. Understanding its function and significance is key to maintaining the performance and reliability of truck systems.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket made from a doughnut-shaped piece of elastic material. It functions by being seated in a groove and compressed during assembly between two or more parts, creating a seal at the interface. O-Rings are widely used in mechanical systems to prevent leakage of fluids and gases, ensuring the system operates within specified parameters 1.

Purpose of the 3076102 O-Ring Seal

This Cummins part is specifically designed to play a role in the sealing mechanisms of commercial trucks. It is associated with various systems or components where fluid integrity is paramount. By providing a barrier against leaks, it helps maintain the efficiency and performance of these systems.

Key Features

The 3076102 is characterized by its material composition, typically a durable elastomer, which allows it to withstand a range of temperatures and pressures. Its dimensions are precisely engineered to fit specific grooves, ensuring a snug fit and effective seal. The design of the O-Ring also incorporates features that enhance its performance and durability in demanding environments.

Benefits of Using the 3076102 O-Ring Seal

Utilizing this Cummins part offers several advantages. It provides improved sealing efficiency, which is crucial for maintaining system performance. Its longevity ensures that replacements are less frequent, reducing maintenance costs. Additionally, the seal is resistant to various environmental factors, including temperature extremes and chemical exposure, which enhances its reliability in commercial truck applications 2.

Installation Considerations

Proper installation of the 3076102 is vital for its performance and longevity. Guidelines recommend ensuring the groove is clean and free of debris before installation. The O-Ring should be lubricated to facilitate seating and to prevent damage during assembly. Careful handling and correct seating are necessary to avoid compromising the seal’s integrity.

Troubleshooting Common Issues

Common issues with O-Ring Seals, such as leaks or failures, can often be traced back to installation errors or environmental factors. Troubleshooting steps include inspecting the seal for signs of wear or damage, checking the groove for cleanliness and proper sizing, and ensuring that the system operates within the O-Ring’s specified temperature and pressure limits.

Maintenance Tips

Regular maintenance of the 3076102 involves periodic inspections to check for signs of wear, deformation, or damage. Conditions such as exposure to extreme temperatures, chemical attack, or physical damage may necessitate replacement. Adhering to manufacturer-recommended inspection intervals helps ensure the seal continues to perform effectively.

Manufacturer Information - Cummins

Cummins is a renowned manufacturer in the automotive and heavy-duty truck industry, known for its commitment to quality and innovation. With a history of producing reliable and high-performance components, Cummins has established a reputation for excellence. The company’s dedication to advancing technology and meeting the needs of its customers underscores its position as a leader in the field.

O-Ring Seal 3076102 Compatibility with Cummins Engines

The O-Ring Seal part number 3076102, manufactured by Cummins, is a critical component designed to ensure the integrity and efficiency of various engine systems. This seal is engineered to fit seamlessly within a range of Cummins engines, providing essential sealing capabilities to prevent leaks and maintain system pressures. Below is a detailed overview of the engines with which this O-Ring Seal is compatible.

Compatible Engines

- ISC CM850

- ISL9 CM2150 SN

- QSB5.9 CM850

- QSB6.7 M CM2250

- QSC8.3 CM850 (CM2850)

- QSK19 CM2350 K105

- QSK19 CM500

- QSK45 CM500

- QSK60 CM500

- QSK60 CM850 MCRS

- QSK60G

- QSK78 CM500

- VTA903 CM2250 V105

Grouping of Compatible Engines

The O-Ring Seal 3076102 is versatile and fits within several engine families and models, including:

-

QSK Series: This includes the QSK19 CM2350 K105, QSK19 CM500, QSK45 CM500, QSK60 CM500, QSK60 CM850 MCRS, QSK60G, and QSK78 CM500. These engines are known for their robust performance and reliability in various industrial and power generation applications.

-

QSB Series: The QSB5.9 CM850 and QSB6.7 M CM2250 are part of this series. These engines are widely used in agricultural and construction equipment due to their durability and efficiency.

-

ISC and ISL Series: The ISC CM850 and ISL9 CM2150 SN engines are part of this series. These engines are commonly found in heavy-duty trucks and buses, providing dependable power and performance.

-

QSC Series: The QSC8.3 CM850 (CM2850) is part of this series. This engine is designed for high-performance applications, including marine and power generation.

-

VTA Series: The VTA903 CM2250 V105 is part of this series. This engine is used in various industrial applications, offering a balance of power and efficiency.

Each of these engines relies on the O-Ring Seal 3076102 to maintain system integrity, ensuring that the engine operates efficiently and reliably. The seal’s design and material composition are tailored to withstand the specific conditions and pressures encountered in these engines, providing a long-lasting and dependable solution for sealing needs.

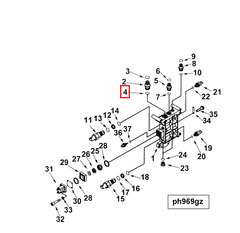

Role of Part 3076102 O-Ring Seal in Engine Systems

This Cummins part is integral to maintaining the integrity and efficiency of various engine systems by ensuring proper sealing in fluid and gas pathways. Its applications span across multiple components, each playing a specific role in the engine’s operation.

Sealing in Fluid Pathways

-

Block and Cylinder: The O-ring seal is used in the block and cylinder to prevent leaks between mating surfaces, ensuring that engine oil and coolant remain within their designated pathways. This helps maintain consistent lubrication and cooling, which are essential for engine longevity and performance.

-

Engine Oil Cooler: In the engine oil cooler, the O-ring seal ensures that engine oil flows through the cooler without leaking, maintaining the oil’s temperature within optimal ranges for engine efficiency and durability.

-

Fuel System Components:

- Fuel Filter: The O-ring seal in the fuel filter housing prevents fuel leaks, ensuring that the fuel system operates under the correct pressure and that contaminants are effectively filtered out.

- Fuel Injector: At the fuel injector, the O-ring seal ensures a tight fit, preventing fuel from leaking into the engine bay and maintaining precise fuel delivery for combustion.

Integration with Electronic Control Systems

- Electronic Control Pressure Valve and Electronic Control Valve: These components rely on the O-ring seal to maintain pressure integrity within the valve housings. This ensures that the electronic control systems can accurately regulate fuel and oil pressures, contributing to overall engine performance and efficiency.

Lubrication and Cooling Systems

-

Engine Lubricating Pump and Scavenge Pump: The O-ring seal is utilized in these pumps to prevent oil leaks, ensuring that the lubrication system can effectively circulate oil to all moving parts, reducing friction and wear.

-

Thermostat Housing: In the thermostat housing, the O-ring seal helps maintain a consistent coolant flow, allowing the thermostat to regulate engine temperature accurately.

Accessory and Plumbing Components

-

Lower Accessory Gasket Set and Lower Engine Gasket Set: These gasket sets often incorporate O-ring seals to ensure that fluids do not leak between the engine block and accessory components, maintaining system integrity.

-

Female Run Tee and Male Union Tee: In these plumbing components, the O-ring seal ensures that connections remain leak-free, whether in the engine oil primer system or the turbocharger oil plumbing.

Starting and Control Systems

-

Starting Motor Mounting: The O-ring seal is used in the starting motor mounting to prevent fluid leaks around the motor, ensuring that the starting system operates efficiently without contamination.

-

Engine Control Module: In the engine control module housing, the O-ring seal prevents environmental contaminants from entering, protecting the sensitive electronic components within.

Turbocharger Systems

- Turbocharger and Turbocharger Oil Plumbing: The O-ring seal is critical in turbocharger systems to maintain the integrity of oil pathways, ensuring that the turbocharger receives consistent lubrication for optimal performance and longevity.

Conclusion

The 3076102 O-Ring Seal plays a significant role in various engine systems by providing reliable seals in fluid and gas pathways, contributing to the overall efficiency, performance, and durability of the engine. Proper installation, maintenance, and understanding of its applications are essential for ensuring the longevity and reliability of commercial truck systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.