This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

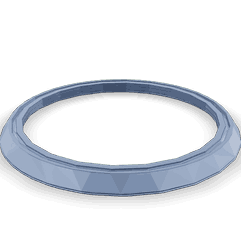

The Cummins 3076203 Dust Seal is a component designed to prevent the ingress of contaminants into the mechanical systems of commercial trucks. Its role is significant in maintaining the integrity and performance of truck components by ensuring that dust and debris do not interfere with the operation of moving parts.

Basic Concepts of Dust Seals

Dust seals, also known as lip seals or exclusion seals, are designed to keep contaminants out of mechanical systems while allowing for the passage of lubricants. They function by creating a barrier between the internal components and the external environment. Typically made from elastomeric materials, dust seals are widely used in various mechanical systems to protect bearings, shafts, and other rotating parts from dirt and dust 1.

Purpose of the 3076203 Dust Seal

The 3076203 Dust Seal plays a role in the operation of a truck by safeguarding critical components from environmental contaminants. It is positioned to cover gaps and openings in the truck’s mechanical system, ensuring that dust and debris do not enter and cause wear or damage to internal parts. This seal contributes to the smooth operation and longevity of the truck’s components by maintaining a clean operating environment 2.

Key Features

The 3076203 Dust Seal is characterized by several key features that enhance its performance and durability. It is constructed from high-quality elastomeric materials, which provide flexibility and resistance to wear. The design includes a lip that contacts the shaft or housing, creating a seal that effectively blocks contaminants while allowing for movement. Additionally, the seal may feature reinforcement materials to improve its durability under dynamic conditions 3.

Benefits of Using the 3076203 Dust Seal

Utilizing the 3076203 Dust Seal offers several advantages. It contributes to improved durability of the truck’s components by preventing contaminant ingress, which can lead to premature wear. Enhanced performance is achieved through the maintenance of clean operating conditions, ensuring that parts function as intended. Increased reliability of the truck’s mechanical system is also a benefit, as the seal helps to reduce the risk of failure due to contamination 4.

Installation Process

Proper installation of the 3076203 Dust Seal is crucial for its effective function. The process involves cleaning the area where the seal will be installed to remove any debris that could compromise the seal. The seal should be carefully positioned to ensure a proper fit without damage to the lip. Tools such as seal installation tools may be required to ensure the seal is seated correctly without distortion 5.

Troubleshooting Common Issues

Common problems associated with dust seals include leaks, wear, and failure to seat properly. These issues can arise from incorrect installation, environmental factors, or material degradation. Solutions may involve re-installation, replacement of the seal, or addressing environmental conditions that contribute to seal degradation 6.

Maintenance Tips

Regular maintenance practices can prolong the life of the 3076203 Dust Seal. Inspection routines should be established to check for signs of wear or damage. Cleaning procedures should be implemented to remove any accumulated contaminants that could affect the seal’s performance. Additionally, ensuring that the seal is correctly installed and that the surrounding components are in good condition will contribute to the seal’s longevity 7.

Conclusion

The 3076203 Dust Seal is a vital component in the maintenance and operation of commercial truck engines. By preventing the ingress of contaminants, it ensures the longevity and performance of engine components. Proper installation, regular maintenance, and prompt troubleshooting of issues are essential for maximizing the benefits of this Cummins part.

-

Automotive Braking Systems, Nicholas Goodnight and Kirk Van Gelder, Jones & Bartlett Learning, 2018.

↩ -

Automotive Heating Ventilation and Air Conditioning, Quansheng Zhan, Shengbo Eben, Li Kun Deng, Jones Bartlett Learning, 2018.

↩ -

Proceedings of the 5th Commercial Vehicle Technology Symposium CVT, Karsten Berns, Klaus Dressler, Patrick Fleischmann, Daniel Grges, Ralf Kalmar, Bernd Sauer, Nicole Stephan, Roman Teutsch, Martin Thul, Springer, 2018.

↩ -

Automotive Technician Training, Second Edition, Tom Denton and Hayley Pells, Routledge, 2022.

↩ -

QSK60 CM2350 K117, Bulletin Number 4367450, Operation and Maintenance Manual.

↩ -

Automotive Braking Systems, Nicholas Goodnight and Kirk Van Gelder, Jones & Bartlett Learning, 2018.

↩ -

Automotive Technician Training, Second Edition, Tom Denton and Hayley Pells, Routledge, 2022.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.