This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3093813 O-Ring Seal is a component designed to ensure the integrity of fluid systems in commercial trucks. Its role is to provide a reliable seal in various applications, contributing to the efficient operation of the vehicle. Understanding its purpose and significance is vital for maintaining the performance and longevity of truck systems.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket with a circular cross-section, designed to create a seal between two or more parts. It functions by deforming slightly when compressed, filling the gap between mating surfaces and preventing fluid or gas leakage. O-Ring Seals are widely used in mechanical systems due to their simplicity, effectiveness, and versatility in various applications 1.

Purpose of the Cummins 3093813 O-Ring Seal

The Cummins 3093813 O-Ring Seal plays a specific role in the operation of a truck by ensuring a tight seal in fluid systems. It is typically located in areas where fluid transfer occurs, such as fuel lines, hydraulic systems, and engine components. Its function is to maintain system pressure, prevent leaks, and ensure the efficient transfer of fluids, which is crucial for the truck’s overall performance.

Key Features

The Cummins 3093813 O-Ring Seal is characterized by several key features that enhance its performance. It is made from durable materials, such as nitrile rubber, which provide resistance to a wide range of chemicals and operating temperatures. The design of the O-Ring ensures it can withstand compression and deformation without losing its sealing properties, contributing to its longevity and reliability in demanding environments.

Benefits

Using the Cummins 3093813 O-Ring Seal offers several benefits. It provides improved sealing efficiency, reducing the risk of leaks and maintaining system integrity. Its durability ensures long-term performance, even under harsh operating conditions. Additionally, its resistance to various fluids and temperatures makes it a versatile choice for different applications within commercial trucks.

Installation Process

Proper installation of the Cummins 3093813 O-Ring Seal is crucial for ensuring optimal performance and longevity. The installation process involves cleaning the mating surfaces to remove any debris or contaminants, lubricating the O-Ring to facilitate easy insertion, and carefully placing it into the groove without twisting or damaging it. Ensuring the O-Ring is properly seated will help maintain the seal’s integrity and efficiency.

Troubleshooting Common Issues

Common issues with O-Ring Seals include leaks, which can be caused by improper installation, wear and tear, or exposure to incompatible fluids. Troubleshooting steps include inspecting the O-Ring for signs of damage, ensuring it is correctly installed, and replacing it if necessary. Regular checks and maintenance can help identify and address issues before they lead to significant problems.

Maintenance Tips

Regular maintenance of the Cummins 3093813 O-Ring Seal is important for prolonging its lifespan and ensuring continued reliable performance. This includes periodic inspection for signs of wear or damage, cleaning the mating surfaces during maintenance procedures, and replacing the O-Ring as part of routine service intervals. Keeping the O-Ring and its environment clean and free from contaminants will also contribute to its longevity.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves commercial truck, bus, construction, agricultural, and industrial markets. The company is known for its commitment to reliability, performance, and customer satisfaction, making it a trusted name in the commercial truck industry 2.

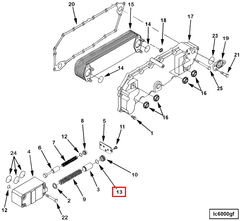

Cummins Engine O-Ring Seal 3093813 Compatibility

The O-Ring Seal part number 3093813, manufactured by Cummins, is a critical component designed to ensure the integrity of various engine systems. This seal is engineered to fit seamlessly within the engine architecture, providing a reliable barrier against leaks and maintaining system pressure.

QST30 CM2350 T101 and QST30 CM552 Engines

For the QST30 CM2350 T101 and QST30 CM552 engines, the O-Ring Seal 3093813 is specifically tailored to fit into the engine’s critical junctures where fluid or gas containment is essential. These engines, while differing in their specific configurations and applications, share common design elements that allow the seal to integrate effectively.

In these engines, the O-Ring Seal 3093813 is typically used in areas where components interface, such as between the engine block and various auxiliary systems. Its placement is crucial for maintaining the engine’s operational efficiency and longevity.

The seal’s design ensures it can withstand the operational stresses of these engines, including high temperatures, pressures, and vibrations. This compatibility is vital for preventing leaks and ensuring the engine operates within its designed parameters.

By using the O-Ring Seal 3093813, engine maintenance and repair processes are streamlined, as this part is specifically engineered to fit these engine models, ensuring a precise and reliable seal.

Role of Part 3093813 O-Ring Seal in Engine Systems

The part 3093813 O-Ring Seal is instrumental in ensuring the integrity and efficiency of various engine systems. Its application spans across multiple components, each playing a significant role in the overall performance and reliability of the engine.

Bypass Valve

In the bypass valve system, the O-Ring Seal is employed to create a tight seal between the valve and its housing. This seal prevents any leakage of engine oil, ensuring that the valve operates within specified parameters. The seal’s effectiveness is vital for maintaining the correct pressure and flow rates, which are essential for the valve’s function in redirecting oil flow when necessary.

Cooler

When integrated into the cooler system, the O-Ring Seal ensures that coolant or oil, depending on the application, remains contained within the cooling passages. This containment is essential for heat dissipation, as any leakage could lead to inefficient cooling and potential overheating of the engine. The seal’s durability under varying temperatures and pressures is key to its performance in this application.

Engine Oil System

Within the engine oil system, the O-Ring Seal is used at various connection points to prevent oil leaks. This includes seals at oil filters, pressure sensors, and other components where oil lines connect. The seal’s ability to withstand the chemical properties of engine oil, along with its resistance to wear and tear, ensures consistent oil pressure and lubrication throughout the engine.

Lower Engine Gasket Kit

In the lower engine gasket kit, the O-Ring Seal is often used to seal oil passages and coolant channels. Its role here is to prevent any cross-contamination between oil and coolant, as well as to ensure that these fluids remain within their designated paths. This is particularly important for maintaining the engine’s thermal efficiency and preventing damage from fluid mixing.

Overall, the part 3093813 O-Ring Seal plays a significant role in maintaining the operational integrity of these engine systems, contributing to the engine’s overall performance, efficiency, and longevity.

Conclusion

The Cummins 3093813 O-Ring Seal is a vital component in the maintenance and operation of commercial truck engines. Its design and material properties ensure reliable sealing in various engine systems, contributing to the overall performance and longevity of the vehicle. Proper installation, regular maintenance, and understanding its role in engine systems are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.