3093963

O-Ring Seal

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3093963 O-Ring Seal, manufactured by Cummins, is a component designed for use in commercial truck applications. Cummins, a well-established name in the automotive industry, produces this seal to meet the demanding requirements of heavy-duty truck operations. The 3093963 O-Ring Seal is integral to maintaining the efficiency and reliability of various truck systems.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket with a circular cross-section, designed to create a seal between two or more parts. In mechanical systems, O-Ring Seals play a role in preventing leaks of fluids and gases by filling the gap between mating surfaces. They are commonly constructed from materials such as nitrile rubber, silicone, or fluorocarbon, chosen for their durability and resistance to various environmental factors 1.

Purpose of the 3093963 O-Ring Seal in Truck Operations

The 3093963 O-Ring Seal is specifically designed to function within the operational systems of commercial trucks. It is associated with components where fluid or gas sealing is required to maintain system integrity and performance. This seal helps in ensuring that the systems operate efficiently by preventing unwanted leaks that could lead to system failure or inefficiency.

Key Features of the 3093963 O-Ring Seal

The 3093963 O-Ring Seal is characterized by its precise design and manufacturing specifications. It features specific dimensions tailored to fit snugly within the designated applications. The material properties of this seal are selected to withstand the harsh conditions typical in commercial truck operations, including exposure to high temperatures, pressure variations, and corrosive substances.

Benefits of Using the 3093963 O-Ring Seal

Utilizing the 3093963 O-Ring Seal offers several advantages. It provides enhanced sealing efficiency, contributing to the overall reliability of the truck’s systems. Its durability ensures long-term performance, even under demanding conditions. Additionally, the seal’s resistance to various operating conditions helps in maintaining the integrity of the systems it is part of.

Installation and Maintenance

Proper installation of the 3093963 O-Ring Seal involves preparing the mating surfaces to ensure a clean and smooth fit. Following torque specifications during installation is important to avoid damage to the seal or the components it interfaces with. Regular maintenance, including inspection for wear and proper lubrication where applicable, can help in ensuring the longevity and optimal performance of the seal.

Troubleshooting Common Issues

Common issues with O-Ring Seals, such as leaks or failures, can often be traced back to installation errors, environmental factors, or wear and tear. Troubleshooting these problems involves a systematic approach to identify the root cause, whether it be improper installation, exposure to incompatible substances, or natural degradation over time. Addressing these issues promptly can help in maintaining the efficiency of the truck’s systems.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and technological advancements have made it a preferred choice for commercial vehicle manufacturers and operators worldwide 2.

Role of Part 3093963 O-Ring Seal in Engine Systems

The 3093963 O-Ring Seal is integral to maintaining the integrity and efficiency of various engine systems. Its application spans across multiple components, ensuring that each system operates within optimal parameters.

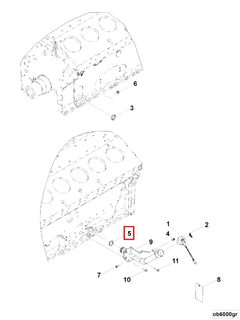

Integration with Engine Components

-

Arrangement: The O-Ring Seal is strategically placed within the engine arrangement to prevent leaks and ensure that fluids remain contained within their designated pathways. This placement is vital for maintaining pressure and preventing contamination between different engine sections.

-

Oil Fill System: In the oil fill system, the O-Ring Seal is used to create a tight seal around the oil fill cap and other components. This ensures that oil does not escape during operation, thereby maintaining the lubrication system’s efficiency and prolonging the life of moving parts.

-

Lower Engine Gasket Kit: When incorporated into the lower engine gasket kit, the O-Ring Seal plays a role in sealing various joints and connections. This is essential for preventing oil and coolant leaks, which can lead to engine damage if not addressed promptly.

-

Lower Engine Gasket Set: Similar to its function in the gasket kit, within the lower engine gasket set, the O-Ring Seal ensures that all gaskets are properly sealed. This comprehensive sealing approach helps in maintaining the engine’s overall performance and reliability.

-

Package: In packaged engine components, the O-Ring Seal is often included to ensure that all parts are pre-sealed for easy installation. This reduces the risk of human error during assembly and ensures that the engine is ready for operation upon installation.

-

Product Installation: During the installation of engine components, the O-Ring Seal is crucial for creating a secure fit between mating surfaces. This is particularly important in high-pressure areas where even a small leak can lead to significant issues.

The 3093963 O-Ring Seal, through its precise application in these components, contributes to the seamless operation of engine systems, enhancing both performance and durability.

Conclusion

The 3093963 O-Ring Seal by Cummins is a critical component in the maintenance and efficiency of commercial truck and engine systems. Its precise design, durable materials, and strategic application across various engine components ensure optimal performance and reliability. Proper installation, maintenance, and prompt troubleshooting of common issues are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.