3094014

O-Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The 3094014 O-Ring Gasket is a component manufactured by Cummins, a well-established name in the commercial truck industry. This gasket is specifically designed for use in various sealing applications within commercial trucks, ensuring the efficient operation of critical systems.

Basic Concepts of O-Ring Gaskets

An O-Ring Gasket is a circular ring, typically made from elastomers, that provides a seal between two or more parts. Its primary function is to prevent the leakage of fluids or gases in dynamic or static applications. Common materials used in the construction of O-Ring Gaskets include nitrile rubber, silicone, and fluorocarbon elastomers, each offering different levels of resistance to temperature, chemicals, and compression set 1.

Purpose of the 3094014 O-Ring Gasket in Truck Operation

The 3094014 O-Ring Gasket plays a role in the sealing mechanisms of commercial trucks. It is associated with various systems or components, such as fuel injectors, where it helps maintain the integrity of the fuel system by preventing leaks. Its proper function ensures that the truck operates efficiently, with minimal risk of fluid leakage that could lead to performance issues or safety hazards 2.

Key Features

The 3094014 O-Ring Gasket is characterized by its precise design and material properties. It is made from high-quality elastomers that offer excellent resistance to the harsh conditions found in commercial truck environments. Its unique characteristics include a specific durometer rating that ensures it can withstand the pressures and temperatures encountered in its applications, enhancing its performance and reliability.

Benefits

Utilizing the 3094014 O-Ring Gasket offers several advantages. It provides improved sealing efficiency, which contributes to the overall performance and reliability of the truck’s systems. Its durability ensures a longer service life, potentially leading to cost savings over time by reducing the frequency of replacements. Additionally, its design and material properties contribute to maintaining system integrity under various operating conditions 3.

Installation Considerations

For optimal performance and longevity, the 3094014 O-Ring Gasket should be installed according to specific guidelines. It is important to ensure that the mating surfaces are clean and free from any debris that could compromise the seal. Proper lubrication during installation can also help prevent damage to the O-Ring and ensure a snug fit. Following these best practices will help maintain the gasket’s effectiveness and extend its service life.

Troubleshooting Common Issues

Common problems associated with O-Ring Gaskets include leaks, which can be caused by improper installation, degradation of the material, or incorrect sizing. To address these issues, it is important to inspect the gasket and the mating surfaces for any signs of wear or damage. Replacing the gasket with a correctly sized and appropriately rated O-Ring can resolve most sealing issues.

Maintenance Tips

Regular maintenance of the 3094014 O-Ring Gasket is key to preventing failures and extending its service life. This includes periodic inspection for signs of wear or degradation, ensuring that mating surfaces remain clean, and replacing the gasket as part of routine maintenance schedules. Adhering to these practices can help maintain the integrity of the sealing systems in commercial trucks.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. Its extensive product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicle applications 4.

Cummins Engine O-Ring Gasket 3094014 Compatibility

The O-Ring Gasket part number 3094014, manufactured by Cummins, is designed to fit seamlessly with several engine models. This gasket is crucial for ensuring a proper seal between engine components, preventing leaks and maintaining optimal performance.

QST30 Engines

The O-Ring Gasket 3094014 is compatible with the following QST30 engines:

- QST30 CM2350 T101

- QST30 CM552

This gasket is engineered to fit precisely within the specified dimensions of these engines, ensuring a reliable seal and enhancing the overall efficiency of the engine. Its compatibility with these models underscores its versatility and importance in maintaining engine integrity.

Application Considerations

When installing the O-Ring Gasket 3094014, it is essential to follow the manufacturer’s guidelines to ensure a proper fit and function. This includes verifying the gasket’s placement and ensuring it is correctly aligned with the engine’s mating surfaces. Proper installation is critical to avoid potential leaks and maintain the engine’s performance.

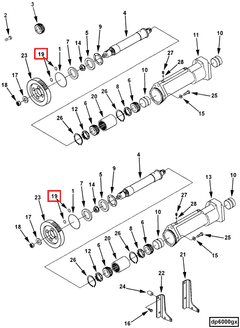

Role of Part 3094014 O-Ring Gasket in Engine Systems

The part 3094014 O-Ring Gasket is integral to the sealing mechanisms within various engine systems, ensuring optimal performance and longevity of the components it interfaces with.

In the compressor system, the O-ring gasket is employed to create a tight seal between the compressor housing and the mating surfaces. This ensures that the pressurized air generated by the compressor is effectively contained, enhancing the efficiency of the air delivery system.

Within the air drive components, the O-ring gasket plays a significant role in maintaining the integrity of the air passages. It prevents air leaks, which could otherwise lead to a drop in system pressure and reduced performance.

For the auxiliary pump drive system, the O-ring gasket is utilized to seal the connections between the pump and its housing. This is essential for maintaining the pressure within the pump system, ensuring consistent fluid delivery to the various engine components.

In the front gear train accessory drive, the O-ring gasket is crucial for sealing the gear housing. This prevents lubricant leakage, which is vital for the smooth operation and longevity of the gear train components.

The fuel pump system also benefits from the O-ring gasket, as it ensures a secure seal between the fuel pump and its housing. This is important for maintaining fuel pressure and preventing fuel leaks, which could pose safety hazards.

When integrating with the fuel pump support kit, the O-ring gasket helps in creating a reliable seal around the fuel pump components, ensuring that the fuel system operates under the correct pressure conditions.

In the context of the lower engine gasket kit and upper engine gasket kit, the O-ring gasket is used to seal various engine compartments. This is important for maintaining the integrity of the engine’s internal environment, preventing coolant, oil, or other fluids from leaking out, and ensuring that the engine operates within its designed parameters.

Overall, the part 3094014 O-Ring Gasket is a fundamental component in ensuring the sealing efficiency across a variety of engine systems, contributing to the overall reliability and performance of the engine.

Conclusion

The 3094014 O-Ring Gasket by Cummins is a critical component in the maintenance and operation of commercial trucks. Its precise design, high-quality materials, and compatibility with various engine models make it an essential part for ensuring the sealing efficiency of engine systems. Proper installation, regular maintenance, and timely replacement are key to maximizing the performance and longevity of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.