3094129

O-Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3094129 O-Ring Seal is a component designed to ensure the integrity of seals within commercial truck systems. Its role is significant in maintaining the operational efficiency and reliability of truck engines and associated systems.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket with a circular cross-section, used to create a seal between two or more parts. It operates by being compressed within a groove, forming a barrier that prevents the leakage of fluids or gases. O-Ring Seals are widely utilized in mechanical systems for their effectiveness in sealing dynamic and static applications 1.

Purpose of the Cummins 3094129 O-Ring Seal

This Cummins part is specifically designed to play a role in the sealing mechanisms of truck engines. It is associated with various systems or components where maintaining a seal is necessary to ensure the proper function of the engine and to prevent leaks that could lead to system failure or inefficiency.

Key Features

The Cummins 3094129 O-Ring Seal is characterized by its material composition, typically made from durable elastomers that provide flexibility and resistance to a range of temperatures and chemicals. Its design includes precise dimensions to fit specific grooves and applications, ensuring a snug fit and effective seal. Unique attributes may include enhanced resistance to wear and tear, as well as compatibility with various fluids encountered in truck engine systems 2.

Benefits

This part offers several benefits, including improved sealing efficiency which helps in maintaining system pressure and preventing leaks. Its durability ensures long-term performance under demanding conditions, and its resistance to various operating conditions makes it suitable for the harsh environments typical of commercial truck operations 3.

Installation Considerations

Proper installation of the Cummins 3094129 O-Ring Seal is vital for its performance and longevity. It should be installed in a clean groove free from debris, with careful attention to avoid damage to the O-Ring. Correct sizing and compression are also important to ensure an effective seal without over-stressing the material 4.

Troubleshooting Common Issues

Common issues with O-Ring Seals, such as leaks, wear, and failure, can often be traced to improper installation, environmental factors, or natural wear over time. Identifying the cause of these issues is key to addressing them effectively, whether it involves replacing the seal, cleaning the groove, or adjusting operational conditions.

Maintenance Tips

Regular maintenance of the Cummins 3094129 O-Ring Seal involves periodic inspection for signs of wear or damage, cleaning the sealing area to remove contaminants, and replacing the seal as necessary. Adhering to manufacturer guidelines for maintenance intervals and conditions can help prolong the service life of the seal and maintain system integrity.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction, providing reliable components that contribute to the efficiency and performance of commercial vehicles.

Cummins Engine O-Ring Seal 3094129 Compatibility

The O-Ring Seal part number 3094129, manufactured by Cummins, is designed to ensure the integrity of various engine systems. This seal is engineered to fit seamlessly within the specified engine models, providing a reliable barrier against leaks and maintaining system pressure.

QST30 CM2350 T101 and QST30 CM552 Engines

The O-Ring Seal 3094129 is compatible with both the QST30 CM2350 T101 and QST30 CM552 engines. These engines, while differing in specific configurations, share common design elements that necessitate the use of this particular seal. The seal’s precision fit ensures that it effectively prevents fluid leakage, thereby maintaining the operational efficiency and longevity of the engine.

In these engines, the O-Ring Seal 3094129 is typically used in areas where fluid containment is crucial. Its placement in high-pressure zones and critical junctures underscores its importance in the overall engine performance. The seal’s material and design are tailored to withstand the operational stresses and environmental conditions these engines encounter, ensuring durability and consistent performance.

Role of Part 3094129 O-Ring Seal in Engine Systems

This part is instrumental in ensuring the integrity and efficiency of various engine systems. Its application spans across multiple components, each playing a significant role in the overall performance and longevity of the engine.

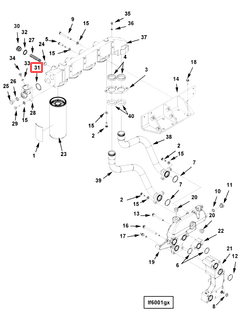

Integration with Filters

In the context of filters, particularly the full flow oil filter and lubricating oil filter, the O-Ring Seal is employed to create a tight, leak-proof connection between the filter elements and the engine block or filter housing. This seal is vital for maintaining the pressure within the filtration system, ensuring that oil is effectively filtered before circulating through the engine. The seal prevents any bypass of unfiltered oil, which could lead to engine wear and reduced efficiency.

Lubricating Oil Systems

When it comes to the lubricating oil system, the O-Ring Seal is used in the filter head adapter kit and the lube oil filter head. These components are designed to manage the flow of lubricating oil to various engine parts. The seal ensures that there is no leakage at the connection points, maintaining the system’s pressure and ensuring consistent lubrication to critical engine components. This is particularly important in high-performance engines where lubrication is key to preventing overheating and mechanical failure.

Top-Level Assembly Heads

In the lubricating oil filter (top-level assembly) head and similar components, the O-Ring Seal plays a role in securing the assembly to the engine. These assemblies are often complex, with multiple moving parts and connections. The seal ensures that the assembly remains securely attached, preventing any oil leaks that could compromise the engine’s lubrication system.

Package and Upfit Kit Applications

In package and upfit kits, which are often used for engine modifications or upgrades, the O-Ring Seal is a common component. These kits may include various engine parts that require secure connections to function correctly. The seal ensures that all components within the kit are properly sealed, contributing to the overall effectiveness of the engine modification.

Product Installation

During the product installation phase, the O-Ring Seal is often one of the first components to be installed. Its proper placement is essential for the successful assembly of engine parts. Whether it’s a new engine build or a repair, the seal’s role in creating a secure, leak-free connection cannot be overstated.

Conclusion

In summary, the Cummins 3094129 O-Ring Seal is a fundamental component in various engine systems, ensuring the integrity of connections, preventing leaks, and contributing to the efficient operation of the engine. Its application across different components highlights its versatility and importance in engine maintenance and performance.

-

Randall, Martynn. Haynes Manual on Diesel Engines. Haynes Publishing, 2015.

↩ -

Hilgers, Michael. The Drivers Cab. Springer Vieweg, 2022.

↩ -

Hu, Haoran, Simon J Baseley, and Xubin Song. Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International, 2021.

↩ -

Cummins Inc. X15 CM2350 X116B - Performance Series. Bulletin Number 5411187: Operation and Maintenance Manual.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.