3094339

O-Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction To O-Ring Seals

O-ring seals are critical in various mechanical systems, particularly in commercial trucks. These seals are designed to create a tight barrier between two surfaces, preventing the leakage of fluids or gases. The unique design of O-rings allows them to withstand high pressure and temperature, making them essential in many industrial applications 1.

How An O-Ring Seal Works

An O-ring seal functions by being compressed between two surfaces, forming a robust barrier against fluid or gas leakage. Typically made from rubber or synthetic polymers, the seal’s material offers flexibility and resilience, ensuring a dependable seal under diverse conditions. When pressure is exerted, the O-ring slightly deforms, creating a seal that effectively contains the substance within 2.

The Purpose Of The Cummins 3094339 O-Ring Seal

The Cummins 3094339 O-ring seal is designed for use in commercial truck engines. Its primary function is to ensure a tight seal between moving parts, preventing oil or fuel leaks that could jeopardize engine performance or pose safety risks. By maintaining a secure seal, the O-ring contributes to the integrity of the engine’s lubrication system, ensuring smooth operation and longevity 3.

Role In Truck Operation

Within commercial truck engines, the O-ring seal is pivotal in upholding engine efficiency and reliability. By preventing leaks, the O-ring aids in maintaining proper oil pressure, thereby reducing wear on engine components and preventing overheating. This, in turn, enhances the overall performance and lifespan of the engine, ensuring the truck can operate dependably over extensive distances and under varied conditions 1.

Troubleshooting And Maintenance

Consistent inspection and maintenance of the O-ring seal are crucial to sustaining its effectiveness. Mechanics should vigilantly check for signs of wear, such as cracks, deformation, or excessive compression, which may signal the need for O-ring replacement. Moreover, ensuring that the mating surfaces are clean and devoid of debris can help prevent damage to the O-ring and maintain a secure seal 2.

When addressing issues related to the O-ring seal, it is imperative to pinpoint the root cause of any leaks or performance problems. This may entail inspecting the O-ring for damage, verifying the proper alignment and condition of the mating surfaces, and ensuring that the seal is correctly installed and compressed. In certain instances, replacing the O-ring or other components may be necessary to resolve the issue 3.

Cummins: A Leader In Engine Technology

Cummins stands as a distinguished manufacturer of engines and related components for commercial trucks and other heavy-duty applications. With a steadfast commitment to quality and innovation, Cummins has solidified its reputation as a trusted provider of reliable and efficient engine solutions. The company’s extensive product range, including the 3094339 O-ring seal, is engineered to meet the rigorous demands of the commercial trucking industry, ensuring optimal performance and durability 1.

Compatibility with Cummins Engines

This Cummins part is designed to ensure the integrity of various engine systems. It is engineered to fit seamlessly within specified engine models, providing a reliable barrier against leaks and maintaining the necessary pressure within the engine’s compartments.

B3.3 and QSB3.3 CM2250 EC Engines

The 3094339 is compatible with the B3.3 and QSB3.3 CM2250 EC engines. These engines are known for their robust design and efficiency, often utilized in a variety of applications from agricultural machinery to industrial equipment. The seal’s precision fit ensures that it effectively prevents fluid leakage, thereby maintaining the engine’s operational integrity and longevity.

QST30 CM2350 T101 and QST30 CM552 Engines

For the QST30 CM2350 T101 and QST30 CM552 engines, the 3094339 is equally essential. These engines are part of Cummins’ QST series, which is renowned for its high performance and reliability in demanding environments. The seal’s design allows it to conform to the specific contours of these engines, ensuring a tight seal that is crucial for maintaining optimal engine performance and preventing costly downtime due to leaks.

Each of these engines benefits from the 3094339’s ability to withstand high temperatures and pressures, making it a vital component in the overall maintenance and operation of the engine systems 1.

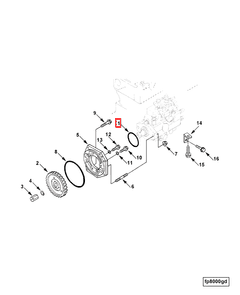

Role of 3094339 O-Ring Seal in Engine Systems

The 3094339 O-Ring Seal is an essential component in ensuring the integrity and efficiency of various engine systems. Its application spans across multiple components, each playing a distinct role in the overall functionality of the engine.

Integration with Engine Components

-

Complete Engine Gasket Kit: The O-Ring Seal is utilized within the gasket kit to provide a reliable seal between mating surfaces, preventing leaks and ensuring that fluids and gases remain contained within their designated pathways.

-

Cover and Front Gear: When installed in the cover and front gear assemblies, the O-Ring Seal helps maintain a tight seal, which is vital for the proper operation of these components. This ensures that lubricants stay in place, reducing friction and wear.

-

Drive and Tachometer: In the drive mechanism and tachometer systems, the O-Ring Seal plays a role in sealing connections and interfaces, which is important for accurate readings and smooth operation of these components.

-

Filter and Oil Bypass: The seal is integral in the filter and oil bypass systems, where it prevents oil leaks and ensures that the filtration process is effective. This contributes to maintaining clean oil, which is essential for engine longevity.

-

Fuel Injection Pump and Fuel Pump: Within the fuel injection pump and fuel pump assemblies, the O-Ring Seal ensures that fuel is delivered without leaks, maintaining the precision required for efficient combustion.

-

Fuel Pump Mounting: The seal is used in the mounting of the fuel pump to prevent any fuel leakage, which is crucial for safety and performance.

-

Gasket Kit: In a broader gasket kit application, the O-Ring Seal is employed to ensure that all gasketed joints are secure, contributing to the overall sealing integrity of the engine.

-

Mounting and Fuel Pump: For components that require mounting, such as the fuel pump, the O-Ring Seal ensures that the mounting process does not result in any fluid leaks, which could compromise engine performance.

-

Overhaul Kit: During engine overhauls, the O-Ring Seal is a key component in the overhaul kit, used to replace worn seals and ensure that the refurbished engine operates efficiently.

-

Pump and Fuel Systems: In various pump and fuel system applications, the O-Ring Seal is vital for maintaining pressure and preventing leaks, which is essential for the consistent delivery of fuel to the engine.

-

Fuel Injection and Tachometer Drive: Finally, in fuel injection systems and tachometer drives, the O-Ring Seal ensures that all connections are sealed, contributing to the accurate measurement of engine performance and the efficient delivery of fuel 2.

Conclusion

The Cummins 3094339 O-ring seal is a critical component in commercial truck engines, offering a reliable seal that prevents leaks and upholds engine performance. By understanding the role and significance of the O-ring seal, mechanics and fleet operators can ensure their trucks operate efficiently and reliably, minimizing downtime and maximizing productivity. Regular inspection and maintenance of the O-ring seal are essential to its continued effectiveness, helping to prevent issues and extend the lifespan of the engine 3.

-

Hilgers, Michael. Entire Vehicle: Second Edition. Springer Nature, 2023.

↩ ↩ ↩ ↩ -

Gilles, Tim. Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning, 2020.

↩ ↩ ↩ -

Duffy, Owen C, and Gus Wright. Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning, 2016.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.