3099408

O-Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

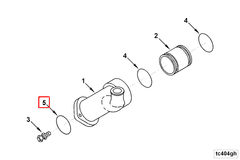

The Cummins 3099408 O-Ring Seal is a critical component designed to maintain the integrity of fluid systems within commercial trucks. Its role is to provide a reliable seal in various applications, contributing to the efficient operation of the vehicle. Understanding its function and significance is essential for maintaining the performance and longevity of truck systems.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket with a circular cross-section, designed to create a seal between two or more parts. It functions by being compressed within a groove, forming a barrier that prevents the leakage of fluids or gases. O-Ring Seals are widely used in mechanical systems due to their simplicity, effectiveness, and versatility in sealing applications 1.

Purpose of the 3099408 O-Ring Seal in Truck Operation

The 3099408 O-Ring Seal plays a crucial role in the operation of a truck by ensuring the sealing of fluid pathways within the engine or transmission systems. Its location is typically within areas where fluid dynamics are critical, such as around fittings, flanges, or within the engine block. The function of this seal is to maintain system pressure, prevent leaks, and ensure the purity of the fluids by keeping contaminants out 2.

Key Features of the 3099408 O-Ring Seal

The design and material characteristics of the 3099408 O-Ring Seal contribute significantly to its effectiveness and durability. Crafted from high-quality elastomers, it is engineered to withstand a range of temperatures and pressures. Its material properties allow it to flex and conform to the surfaces it seals, ensuring a tight fit even under dynamic conditions 3.

Benefits of Using the 3099408 O-Ring Seal

The advantages provided by the 3099408 O-Ring Seal include enhanced sealing performance, which leads to improved system efficiency. Its durability ensures a longer service life, reducing the frequency of replacements. Additionally, the seal is resistant to various environmental factors, such as oils, fuels, and temperature extremes, which are commonly encountered in truck operations 4.

Installation and Maintenance

Proper installation of the 3099408 O-Ring Seal is vital for its effective performance. It should be seated correctly within the designated groove without twists or folds. Regular maintenance practices, such as inspection for wear or damage and replacement as needed, are recommended to ensure continued sealing integrity and system reliability 5.

Troubleshooting Common Issues

Common problems associated with O-Ring Seals may include leaks, which can be caused by improper installation, wear, or exposure to incompatible fluids. Troubleshooting steps involve inspecting the seal for damage, ensuring correct installation, and verifying compatibility with the system’s fluids and operating conditions 6.

Manufacturer: Cummins

Cummins is a renowned manufacturer with a history of producing high-quality automotive components. Their reputation is built on a commitment to innovation, reliability, and customer satisfaction. Cummins’ products, including the 3099408 O-Ring Seal, are designed with precision and engineered to meet the demanding requirements of commercial truck applications 7.

Cummins O-Ring Seal 3099408 Compatibility

The Cummins O-Ring Seal part number 3099408 is designed to fit a variety of Cummins engines, ensuring a tight seal in critical areas to prevent leaks and maintain engine efficiency. Here is a detailed overview of its compatibility with the listed engines:

K-Series Engines

- K19

- K38

- K50

The O-Ring Seal 3099408 is compatible with the K-Series engines, including the K19, K38, and K50. These engines are known for their robust design and reliability, often used in various industrial and agricultural applications.

KTA19 Series Engines

- KTA19GC

- KTA19GC CM558

The KTA19GC and KTA19GC CM558 engines also support the use of the O-Ring Seal 3099408. These engines are typically used in power generation and other heavy-duty applications, requiring durable sealing solutions to maintain performance.

QSK19 Series Engines

- QSK19 CM2350 K105

- QSK19 CM2350 K114

- QSK19 CM2350 K144G

The QSK19 series engines, including the QSK19 CM2350 K105, QSK19 CM2350 K114, and QSK19 CM2350 K144G, are compatible with the O-Ring Seal 3099408. These engines are widely used in marine, power generation, and industrial applications, where reliability and efficiency are paramount.

QSK19 Series Engines with Higher Power Ratings

- QSK19 CM500

- QSK19 CM850 MCRS

The higher power rating QSK19 engines, such as the QSK19 CM500 and QSK19 CM850 MCRS, also utilize the O-Ring Seal 3099408. These engines are designed for demanding applications, requiring high performance and durability.

QSK Series Engines

- QSK19G

- QSK60G

- QST30 CM552

The QSK19G, QSK60G, and QST30 CM552 engines are also compatible with the O-Ring Seal 3099408. These engines are known for their versatility and are used in a range of applications, from construction equipment to marine vessels.

By ensuring that the O-Ring Seal 3099408 is used in these engines, operators can maintain the integrity of their systems, prevent leaks, and extend the lifespan of their equipment.

Role of Part 3099408 O-Ring Seal in Engine Systems

The Part 3099408 O-Ring Seal is instrumental in ensuring the integrity and efficiency of various engine systems by providing reliable sealing solutions. Here’s how it integrates with the specified components:

Aftercooler Water Plumbing

In the aftercooler water plumbing system, the O-Ring Seal ensures that there are no leaks in the connections between the water tubes and the aftercooler. This maintains the efficiency of the aftercooling process, allowing the engine to operate at optimal temperatures.

Auxiliary Cooling System

Within the auxiliary cooling system, the O-Ring Seal is used at various connection points to prevent coolant leakage. This ensures that the auxiliary cooling system can effectively manage engine temperatures, especially under high-load conditions.

Engine Oil Cooler

For the engine oil cooler, the O-Ring Seal plays a vital role in sealing the connections between the oil cooler and its plumbing. This prevents oil leaks and maintains the effectiveness of the oil cooling process, which is essential for prolonging engine life.

Keel Cooling

In keel cooling systems, the O-Ring Seal is employed to ensure that the cooling water passages remain leak-free. This is particularly important in marine applications where keel cooling is used to manage engine temperatures in harsh environments.

Oil Cooler Water Plumbing

The O-Ring Seal is critical in the oil cooler water plumbing to prevent any mixing of oil and water, ensuring that both systems operate efficiently and without contamination.

Starting Aid Kit

Although less common, the O-Ring Seal may be used in starting aid kits to seal fluid connections, ensuring that the starting aid system functions correctly without any fluid loss.

Torque Converter Cooler

In the torque converter cooler, the O-Ring Seal ensures that the cooling fluid passages are sealed, maintaining the efficiency of the torque converter and preventing any fluid leaks that could affect transmission performance.

Torque Converter Cooler Plumbing

Similar to the torque converter cooler, the O-Ring Seal in the torque converter cooler plumbing prevents leaks, ensuring that the cooling system operates efficiently and maintains the proper temperature for the torque converter.

Torque Converter Oil Cooler

The O-Ring Seal in the torque converter oil cooler ensures that oil passages are sealed, preventing leaks and maintaining the efficiency of the oil cooling process for the torque converter.

Water By-Pass Tube

In the water by-pass tube system, the O-Ring Seal is used to ensure that the by-pass function operates without leaks, allowing for efficient temperature management within the engine system.

Water Connection Mounting

For water connection mountings, the O-Ring Seal provides a secure seal at the mounting points, preventing water leaks and ensuring the stability and efficiency of the water connections.

Water Manifold

In the water manifold, the O-Ring Seal is used to seal the various connections, ensuring that water distribution within the engine system is efficient and leak-free.

Water Outlet Connection

At the water outlet connection, the O-Ring Seal ensures that the outlet operates without leaks, maintaining the integrity of the cooling system.

Water Outlet Mounting Connection

Similarly, in the water outlet mounting connection, the O-Ring Seal prevents leaks, ensuring that the mounting connection remains secure and efficient.

Water Transfer Connection

For water transfer connections, the O-Ring Seal ensures that the transfer of water within the engine system is leak-free, maintaining the efficiency of the cooling process.

Water Transfer Tube

In the water transfer tubes, the O-Ring Seal is used to seal the connections, preventing any water leaks and ensuring that the transfer tubes operate efficiently.

Water Transfer Tubes

Finally, in the water transfer tubes system, the O-Ring Seal ensures that all tubes are securely sealed, preventing leaks and maintaining the overall efficiency of the water transfer system within the engine.

Conclusion

The Cummins 3099408 O-Ring Seal is a vital component in maintaining the integrity and efficiency of fluid systems within commercial trucks. Its design, material properties, and compatibility with various Cummins engines make it an essential part for ensuring reliable sealing solutions. Proper installation, regular maintenance, and troubleshooting common issues are key to maximizing the performance and longevity of this Cummins part.

-

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩ -

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ -

Wharton, A. J. (1991). Diesel Engines. Butterworth-Heinemann Ltd.

↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for Marine Auxiliary QSB7-DM CM850. Bulletin Number 4310650.

↩ -

Wharton, A. J. (1991). Diesel Engines. Butterworth-Heinemann Ltd.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for Marine Auxiliary QSB7-DM CM850. Bulletin Number 4310650.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.