This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3176552 Tamper-Proof Seal is a specialized component designed to enhance the security and integrity of commercial truck systems. Its role is significant in the context of commercial truck maintenance and operation, providing a means to ensure that critical components remain unaltered and secure 2.

Basic Concepts of Tamper-Proof Seals

Tamper-proof seals are security devices used to indicate whether a component or system has been tampered with. They function by creating a physical bond that is difficult to remove without leaving evidence of tampering. These seals find applications across various industries, including automotive, where they are used to secure critical components and systems against unauthorized access or modification 1.

Purpose of the 3176552 Tamper-Proof Seal

The 3176552 Tamper-Proof Seal plays a specific role in the operation and maintenance of commercial trucks by securing critical components and systems. It ensures the integrity of these components by providing a visible indication if tampering has occurred, thereby maintaining the safety and reliability of the vehicle 2.

Key Features

The 3176552 Tamper-Proof Seal is characterized by several key features that enhance its functionality and reliability. Its design incorporates materials that are resistant to tampering and environmental factors. Unique characteristics include a robust construction that ensures durability and a design that allows for easy inspection and verification of seal integrity 2.

Benefits

Using the 3176552 Tamper-Proof Seal offers several benefits. It improves security by deterring unauthorized access to critical components. It facilitates ease of inspection, allowing for quick verification of seal integrity. Additionally, it contributes to overall vehicle safety and compliance with regulatory standards by ensuring that components remain unaltered and secure 2.

Installation Process

Proper installation of the 3176552 Tamper-Proof Seal involves a series of steps to ensure effective sealing. The process requires specific tools and equipment to apply the seal correctly. Best practices include ensuring the surface is clean and free of debris before application, and verifying that the seal is properly aligned and secured 2.

Troubleshooting Common Issues

Common problems associated with tamper-proof seals may include difficulty in application, seal breakage, or false indications of tampering. Practical solutions involve ensuring proper installation techniques, using the correct tools, and regularly inspecting the seal for signs of wear or damage 2.

Maintenance Tips

Regular maintenance and inspection of the 3176552 Tamper-Proof Seal are recommended to ensure its continued effectiveness and longevity. This includes checking for signs of wear, ensuring the seal remains intact, and replacing it if any signs of tampering or damage are detected 2.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of products and commitment to quality and reliability. The company’s history and reputation underscore the quality and reliability of the 3176552 Tamper-Proof Seal, reflecting Cummins’ dedication to providing high-quality components for the automotive sector 2.

Tamper-Proof Seal 3176552 Compatibility with Cummins Engines

The Tamper-Proof Seal 3176552, manufactured by Cummins, is designed to ensure the integrity and security of various engine components. This seal is compatible with a range of Cummins engines, providing a reliable method to prevent unauthorized access and tampering 2.

K-Series Engines

- K19

- K38

- K50

KTA Series Engines

- KTA19GC

- KTA19GC CM558

- KTA38GC CM558

QSK Series Engines

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

- QSK45 CM500

- QSK50 CM2150 K107

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

- QSK60 CM500

- QSK60 CM850 MCRS

- QSK60G

- QSK78 CM500

QSV Series Engines

- QSV81G

- QSV91-G4 CM558/CM700 V102

- QSV91G

By integrating the Tamper-Proof Seal 3176552 into these engines, Cummins ensures that the engines’ components remain protected against unauthorized access and tampering, thereby maintaining the overall reliability and performance of the engines 2.

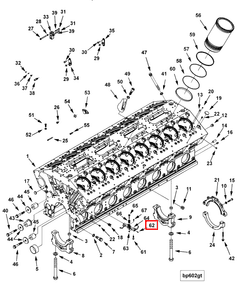

Role of Part 3176552 Tamper-Proof Seal in Engine Systems

The part 3176552 Tamper-Proof Seal is integral to maintaining the integrity and security of various engine components. It ensures that once an assembly is sealed, it remains untouched and unaltered, which is essential for the reliable operation of the engine 2.

Accessory Drive Support and Air Compressor Support

In the accessory drive support and air compressor support systems, the Tamper-Proof Seal prevents unauthorized adjustments or tampering. This is particularly important for maintaining the precise alignment and tension of belts and pulleys, ensuring efficient operation of accessories like the air compressor 2.

Assembly and Short Block Components

For assemblies such as the short block K50G3 and the cylinder block assembly, the seal ensures that internal components remain secure. This is vital for the structural integrity of the engine, preventing any unauthorized modifications that could lead to performance issues or failures 2.

Camshaft and Valve Components

The cam follower housing and camshaft cover benefit from the Tamper-Proof Seal by securing the camshaft and its associated components. This seal ensures that the timing and operation of the camshaft remain consistent, which is essential for the engine’s valve timing and overall performance 2.

Fuel System Components

In the fuel pump and fuel pump & drive (Bosch) systems, the seal ensures that the fuel delivery components are not tampered with. This is important for maintaining the correct fuel pressure and delivery, which are critical for engine performance and efficiency 2.

Lubrication System

For the lubricating oil pump and its cover, the Tamper-Proof Seal ensures that the oil pump settings and internal components are not altered. This is essential for maintaining the correct oil pressure and lubrication throughout the engine, which is vital for reducing wear and ensuring longevity 2.

Piston Cooling and Rocker Assembly

The piston cooling valve and its body, along with the rocker assembly lever, are secured by the Tamper-Proof Seal to ensure that these components operate within their designed parameters. This is important for managing engine temperatures and ensuring smooth valve operation 2.

Long Block Assembly

In the long block assy. - 50, the seal ensures that all integrated components, from the cylinder kit block to the valve tappet assembly housing, remain secure. This comprehensive sealing is essential for the overall reliability and performance of the engine 2.

On Board Spares and Hardware Kit

The on board spares and hardware kit components are also secured by the Tamper-Proof Seal, ensuring that these critical spare parts are not tampered with and remain available for use when needed 2.

Conclusion

By integrating the Tamper-Proof Seal 3176552 across these various engine components, engineers and mechanics can ensure that the engine operates as designed, with all components secured and unaltered, leading to improved reliability and performance 2.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.