This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

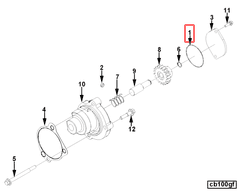

The Cummins 3202179 O-Ring Seal is a component used in commercial trucks to maintain system integrity. It plays a role in ensuring that various systems within the truck operate efficiently by preventing leaks of fluids or gases. The seal’s proper function is integral to the overall performance and reliability of the truck 1.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket with a circular cross-section, designed to create a seal between two or more parts. It operates by being compressed within a groove, forming a barrier that prevents the passage of fluids or gases. O-Ring Seals are widely used in mechanical systems due to their simplicity, effectiveness, and versatility in various applications 2.

Purpose of the 3202179 O-Ring Seal in Truck Operations

The 3202179 O-Ring Seal is specifically designed to function within the systems of commercial trucks. It is involved in sealing connections where fluids or gases are present, ensuring that these substances remain contained within their designated pathways. This seal is part of systems that require a reliable barrier to maintain operational efficiency and prevent contamination or loss of critical substances 3.

Key Features of the 3202179 O-Ring Seal

The design and material characteristics of the 3202179 O-Ring Seal contribute to its effectiveness. It is crafted from materials that offer durability and resistance to a range of chemicals, ensuring it can withstand the harsh environments typical of commercial truck operations. Additionally, the seal is capable of operating within a specified temperature range, maintaining its integrity under varying conditions 1.

Benefits of Using the 3202179 O-Ring Seal

Utilizing the 3202179 O-Ring Seal in commercial trucks offers several advantages. It contributes to improved system efficiency by ensuring that fluids and gases are properly contained. This containment reduces the need for frequent maintenance, as the seal helps to prevent leaks that could lead to system failures. Furthermore, the seal’s reliability in harsh operating conditions enhances the overall dependability of the truck’s systems 2.

Installation and Maintenance Guidelines

Proper installation of the 3202179 O-Ring Seal involves preparing the sealing surface to ensure it is clean and free of debris. The seal should be correctly seated within its groove to ensure optimal performance. Regular maintenance, including inspection for wear or damage, is recommended to ensure the longevity and effectiveness of the seal. Following these guidelines helps maintain the seal’s performance and extends its service life 3.

Troubleshooting Common Issues

Common issues with O-Ring Seals, such as leaks or failure, can often be traced back to improper installation, wear, or exposure to incompatible substances. Troubleshooting these problems involves inspecting the seal and its seating area for signs of damage or misalignment. Addressing these issues promptly can help restore system integrity and prevent further complications 1.

Compatibility and Application

The 3202179 O-Ring Seal is designed for use in specific applications within commercial trucks. It is compatible with a range of systems where sealing is required to maintain operational efficiency. Understanding its applications and compatibility with other components is important for ensuring it is used correctly within the truck’s systems 2.

Cummins: A Brief Overview

Cummins Inc. is a well-established manufacturer in the commercial vehicle industry, known for its wide range of products and commitment to quality and reliability. The company’s history and reputation underscore the quality and dependability of components like the 3202179 O-Ring Seal, reflecting Cummins’ dedication to excellence in the automotive and heavy-duty truck parts sector 3.

Compatibility with Cummins Engines

This Cummins part is designed to fit a variety of Cummins engines. It is crucial for ensuring a tight and reliable connection in various engine components, preventing leaks and maintaining optimal performance.

ISB/ISD6.7 CM2150 SN, QSX15 CM2250, QSX15 CM2250 ECF, QSX15 CM2350 X105

These engines, part of the Cummins QSX and ISB/ISD series, utilize the 3202179 in several critical applications. This seal is commonly used in fuel systems, oil systems, and other fluid pathways where a secure seal is necessary to prevent leaks and maintain system integrity.

ISBE CM800, ISBE4 CM850

The ISBE and ISBE4 series engines, specifically the CM800 and CM850 models, also incorporate the 3202179. These engines, typically used in industrial and marine applications, benefit from the seal’s ability to provide a reliable barrier in high-pressure environments.

K19, N14 CELECT PLUS

The K19 and N14 CELECT PLUS engines, known for their durability and performance, also use the 3202179. This seal is essential in these engines for maintaining the integrity of various fluid systems, ensuring that the engines operate efficiently and reliably.

QSK19 CM500

The QSK19 CM500 engine, part of the Cummins QSK series, incorporates the 3202179 in its design. This seal is critical for ensuring that the engine’s fluid systems remain sealed and leak-free, contributing to the overall performance and longevity of the engine.

Role of 3202179 in Engine Systems

The 3202179 is integral to maintaining the integrity and efficiency of various engine systems. It is employed in several key areas to ensure proper sealing and prevent leaks, which can significantly impact engine performance and longevity.

Oil Fill and Lubricating Oil Systems

In the oil fill and lubricating oil systems, the O-Ring Seal is used to create a tight seal around the oil fill cap and the lubricating oil pump. This ensures that oil does not leak out, maintaining the necessary lubrication for moving parts within the engine. Proper lubrication is essential for reducing friction and wear on components such as the cylinder and base parts.

Fuel System

Within the fuel system, the O-Ring Seal is positioned around the fuel pump and fuel lines. This seal prevents fuel leaks, which are not only hazardous but also ensure that the fuel delivery system operates efficiently. A secure seal around the fuel pump ensures consistent fuel pressure and flow, which is vital for engine performance.

Engine Barring and Drive Systems

The O-Ring Seal is also utilized in the engine barring and drive systems. In these applications, it helps to seal the connections between the drive components and the engine block. This prevents any lubricants or coolants from escaping, which could lead to inefficient operation or damage to the engine barring mechanism.

Mounting and Base Components

In the arrangement of mounting spacers and base parts, the O-Ring Seal plays a role in sealing the interfaces between these components and the engine block. This is particularly important in high-stress areas where vibrations and thermal expansion could otherwise lead to leaks. Ensuring a solid seal here contributes to the overall stability and reliability of the engine arrangement.

Cylinder and Block Sealing

The cylinder and engine block are critical areas where the O-Ring Seal is employed to prevent coolant or oil leaks. These seals are positioned around gaskets and other sealing surfaces to maintain the integrity of the cooling and lubrication systems. Effective sealing in these areas is essential for preventing contamination and ensuring optimal engine operation.

Conclusion

In summary, the 3202179 O-Ring Seal is a versatile component that enhances the functionality and reliability of various engine systems by providing essential seals in critical applications. Its role in preventing leaks and maintaining system integrity is crucial for the efficient operation of commercial trucks and Cummins engines.

-

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ ↩ ↩ -

Mom, G. (2023). The Evolution of Automotive Engineering: A Handbook. SAE International.

↩ ↩ ↩ -

Boyce, M. P. (2011). Gas Turbine Engineering Handbook 4th Edition. Butterworth-Heinemann.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.