This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

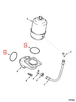

The 3336140 O-Ring Seal, a component manufactured by Cummins, is integral to the commercial truck industry. This Cummins part is designed to ensure the integrity of various systems within commercial trucks.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a gasket with a circular cross-section, used to create a seal between parts to prevent fluid and gas leakage 1. These seals are typically made from elastomers like nitrile rubber, silicone, and fluorocarbon, known for their flexibility and resistance to wear 2.

Purpose of the 3336140 O-Ring Seal in Truck Operations

This O-Ring Seal is utilized in commercial trucks to maintain seals in systems requiring fluid or gas containment. It is often found in areas needing dynamic sealing, such as engine components or fluid transfer systems, contributing to the truck’s operational efficiency and reliability 3.

Key Features of the 3336140 O-Ring Seal

The 3336140 is engineered with a precise cross-sectional diameter, high-quality elastomer material, and a smooth surface finish. These features enhance its effectiveness and durability in heavy-duty applications, ensuring resilience under pressure and minimizing friction and wear.

Benefits of Using the 3336140 O-Ring Seal

Using this O-Ring Seal offers benefits such as improved sealing performance, preventing leaks and maintaining system efficiency. Its durability reduces replacement frequency, and its resistance to temperature extremes and chemicals enhances reliability in commercial truck applications.

Installation Considerations

Proper installation of the 3336140 is crucial for optimal performance. This includes ensuring clean sealing surfaces, using appropriate lubrication, and avoiding over-stretching during placement.

Troubleshooting Common Issues

Common issues with O-Ring Seals include leaks, wear, and improper seating. Troubleshooting involves inspecting for damage, ensuring correct installation, and considering environmental factors affecting seal performance.

Maintenance Tips

Regular maintenance of the 3336140 is recommended. This includes periodic inspection for wear, cleaning to prevent contamination, and replacement according to manufacturer guidelines or when degradation is observed.

Cummins: A Brief Overview

Cummins Inc. is a global leader in power solutions, known for its quality, innovation, and customer satisfaction in the commercial truck industry. Its extensive product range and reliability make it a preferred choice for operators and manufacturers.

Compatibility with Engine Models

The 3336140 is compatible with various Cummins engine models, including QSV91-G4 CM558/CM700 V102, QSV91G, and QSZ90. It ensures optimal sealing and performance, fitting seamlessly within these engines to prevent fluid leakage and maintain system integrity.

Role of the 3336140 O-Ring Seal in Various Engine Systems

This part is crucial in several engine systems:

- Aid Coolant Heater Starting Assembly: Prevents coolant leaks, maintaining optimal engine temperature during startup.

- Assembly Gas Circuit and Circuit Assembly Gas: Ensures smooth gas flow without escape, essential for the fuel injection system.

- Coolant Heater Start Assembly Aid: Maintains coolant pressure and temperature for efficient engine warm-up.

- Engine Cool Assembly Plumbing and Engine Coolant Plumbing: Prevents coolant leaks, ensuring correct engine operating temperature.

- Filter, Lubricating Oil and Filter, Oil Bypass systems: Ensures correct oil flow through filters, maintaining engine component lubrication.

- Gas Circuit Assembly: Maintains gas flow integrity, crucial for the combustion process.

- Housing, Front Gear: Keeps lubricants contained, ensuring smooth gear operation.

- Plumbing, Engine Coolant system: Maintains coolant flow and pressure, fundamental for engine cooling and performance.

Conclusion

The 3336140 O-Ring Seal plays a significant role in the efficiency and reliability of commercial truck engines. Its proper installation, maintenance, and compatibility with various engine models are essential for optimal performance and longevity.

-

Mananathan, R. (2022). Automobile Wheel Alignment and Wheel Balancing. SAE International.

↩ -

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ -

Quigley, J. M. (2023). SAE International’s Dictionary of Testing, Verification and Validation. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.