This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

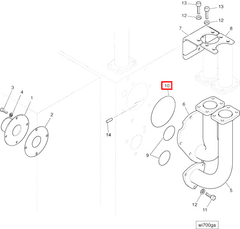

The 3336205 O-Ring Seal is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This Cummins part is specifically designed for use in commercial trucks, where it plays a role in ensuring the integrity of various systems within these vehicles.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket with a circular cross-section, designed to create a seal between two or more parts. In mechanical systems, O-Rings are commonly used to prevent leakage of fluids and gases, ensuring the system operates efficiently. They function by being compressed between flanges on two connecting pieces, and their elastomeric properties allow them to conform to the surfaces they seal against, creating a barrier that prevents the passage of substances 1.

Purpose of the 3336205 O-Ring Seal in Truck Operations

In the context of commercial trucks, the 3336205 O-Ring Seal is utilized in various systems where fluid or gas sealing is required. Its specific location and function can vary depending on the truck’s make and model, but it generally serves to maintain the integrity of seals in engines, transmissions, and other critical systems. By doing so, it helps to ensure that these systems operate under the designed parameters, contributing to the overall efficiency and reliability of the truck 2.

Key Features of the 3336205 O-Ring Seal

The 3336205 O-Ring Seal is engineered with specific design and material characteristics that make it well-suited for heavy-duty applications. It is constructed from durable materials that offer resistance to a wide range of chemicals and can withstand significant temperature variations. These features ensure that the seal remains effective under the demanding conditions typically encountered in commercial truck operations.

Benefits of Using the 3336205 O-Ring Seal

Incorporating the 3336205 O-Ring Seal into truck systems offers several advantages. Its robust design and material properties contribute to improved system reliability, as it is less likely to fail under stress. Additionally, the seal’s durability reduces the need for frequent maintenance, allowing for more consistent vehicle operation. Furthermore, its ability to perform well in challenging conditions enhances the overall performance of the truck, ensuring that it can meet the demands of commercial use.

Installation Considerations

Proper installation of the 3336205 O-Ring Seal is crucial for ensuring its effectiveness and longevity. Best practices include ensuring the sealing surfaces are clean and free of debris before installation, using the correct tools to avoid damaging the O-Ring, and verifying that the seal is properly seated within its groove. Following these guidelines helps to ensure that the seal will perform as intended, providing a reliable barrier against leaks 3.

Troubleshooting Common Issues

O-Ring Seals, including the 3336205 model, can encounter issues such as leaks, extrusion, or degradation over time. Diagnosing these problems involves inspecting the seal for signs of wear or damage, checking the condition of the sealing surfaces, and ensuring that the O-Ring is correctly installed. Addressing these issues may require cleaning or replacing the seal, depending on the severity of the problem.

Maintenance Tips

Regular maintenance of the 3336205 O-Ring Seal is important for ensuring continued optimal performance. This includes periodic inspections to check for signs of wear or damage, and replacing the seal according to the manufacturer’s guidelines or when any issues are detected. Proper maintenance helps to prevent unexpected failures and ensures that the truck’s systems remain efficient and reliable.

Compatibility with Engine Models

The 3336205 O-Ring Seal is designed to fit seamlessly within various engine models, ensuring optimal sealing and performance. This seal is crucial in maintaining the integrity of the engine’s system by preventing leaks and ensuring that components operate efficiently.

Grouping of Engines

QSV81G and QSV91G Engines The O-Ring Seal 3336205 is compatible with the QSV81G and QSV91G engines. These engines are known for their robust design and reliability, often used in heavy-duty applications. The seal fits perfectly in these engines, ensuring that the critical components remain sealed and protected from contaminants.

QSW/QSV82 Engines For the QSW/QSV82 engines, the O-Ring Seal 3336205 is engineered to provide a precise fit. This engine model is designed for versatility and efficiency, making the seal an essential component in maintaining its operational standards. The compatibility ensures that the seal performs consistently under various conditions.

QSW27 and QSW36 Engines The O-Ring Seal 3336205 is also suitable for the QSW27 and QSW36 engines. These engines are part of a series known for their durability and performance. The seal’s design allows it to fit snugly, providing a reliable barrier against leaks and ensuring the engine’s components function optimally.

QSW73 Engine The QSW73 engine benefits from the O-Ring Seal 3336205, which is specifically designed to fit this model. This engine is engineered for high performance and efficiency, and the seal plays a role in maintaining its operational integrity.

QSZ90 Engine Lastly, the QSZ90 engine is another model that is compatible with the O-Ring Seal 3336205. This engine is known for its advanced features and reliability. The seal ensures that the engine’s components are protected, contributing to its overall performance and longevity.

Role of 3336205 O-Ring Seal in Engine Systems

The 3336205 O-Ring Seal is integral to maintaining the integrity and efficiency of various engine systems by ensuring proper sealing in multiple components.

In the water inlet and water outlet connection, the O-Ring Seal prevents coolant leaks, ensuring consistent coolant flow which is vital for engine temperature regulation.

Within the cooler and engine oil assembly cooler, it secures the seal between the housing and the cooler, preventing any oil or coolant leakage that could compromise the cooling efficiency of the engine oil.

For the thermostat housing and thermostat sub-assembly cover, the O-Ring Seal ensures that the thermostat operates within its designed parameters by maintaining a sealed environment, which is essential for accurate temperature control.

In the accy drive pulley housing and oil cooler sub-assembly, the seal prevents any fluid leaks that could affect the performance of accessories driven by the engine.

The front gear train accessory and power take-off assembly housing rely on the O-Ring Seal to maintain pressure integrity and prevent fluid loss, ensuring smooth operation of these components.

For the pump and water pump, the O-Ring Seal is used in the water pump cover and seal water pump mounting kit to ensure that the pump operates efficiently without any coolant escape, which is fundamental for consistent engine cooling.

In the thermostat assembly housing and water assembly pump, the seal plays a role in maintaining the structural integrity and operational efficiency by preventing any fluid ingress or egress that could lead to system failure.

Overall, the 3336205 O-Ring Seal is a small yet significant component that contributes to the reliable operation of various engine systems by ensuring that seals remain intact across a range of critical connections and housings.

Conclusion

The 3336205 O-Ring Seal by Cummins is a critical component in the maintenance and operation of commercial truck engines. Its design and material properties ensure durability and reliability under demanding conditions, contributing to the overall efficiency and reliability of the vehicle. Proper installation, regular maintenance, and understanding its role in various engine systems are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.