This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3336210 O-Ring Seal is a critical component designed to maintain the integrity of fluid systems within commercial trucks. Its role in providing a reliable seal in various applications contributes to the efficient operation of the vehicle. Understanding its purpose and significance is essential for maintaining the performance and longevity of truck systems.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket consisting of a torus (doughnut) shape that creates a seal between two or more parts. It functions by deforming slightly when compressed, filling the gap between mating surfaces to prevent fluid or gas leakage. O-Ring Seals are widely used in mechanical systems due to their simplicity, effectiveness, and versatility in sealing applications 1.

Purpose of the 3336210 O-Ring Seal in Truck Operation

This part plays a specific role in the operation of commercial trucks by ensuring the sealing of fluid pathways within the engine or other systems. Its location and function are vital to maintaining system pressure and preventing leaks, which can lead to inefficiencies or damage 2.

Key Features of the 3336210 O-Ring Seal

The design and material characteristics of the 3336210 O-Ring Seal contribute to its effectiveness and durability. Crafted from high-quality elastomeric materials, it is engineered to withstand a range of temperatures and pressures, ensuring reliable performance in demanding environments 3.

Benefits of Using the 3336210 O-Ring Seal

The advantages provided by this Cummins part include improved sealing performance, which helps maintain system efficiency. Its durability ensures longevity, reducing the need for frequent replacements. Additionally, its resistance to various operating conditions enhances the reliability of truck systems.

Installation and Maintenance

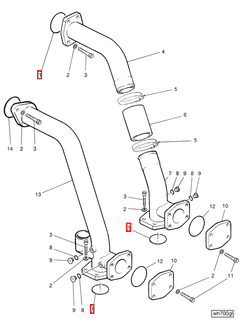

Proper installation of the 3336210 O-Ring Seal involves preparation steps such as cleaning the mating surfaces and ensuring the correct size and fit. Tools required may include lubricants to facilitate installation without damaging the seal. Maintenance tips to ensure longevity and optimal performance include regular inspection for signs of wear or damage and replacement as needed.

Troubleshooting Common Issues

Common problems associated with O-Ring Seals, such as leaks or wear, can often be diagnosed through visual inspection and pressure testing. Steps for resolving these issues may involve cleaning the sealing surfaces, replacing the seal, or addressing underlying causes such as misalignment or excessive pressure.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction.

Cummins O-Ring Seal 3336210 Compatibility with Engine Models

This Cummins part is designed to fit seamlessly with a variety of engine models, ensuring optimal performance and reliability. It is engineered to provide a tight and effective seal, preventing leaks and maintaining system integrity.

Engine Models QSV81G and QSV91G

The O-Ring Seal 3336210 is compatible with the QSV81G and QSV91G engines. These engines are part of Cummins’ lineup of high-performance diesel engines, known for their durability and efficiency. The seal fits precisely in areas where it is needed to prevent fluid or gas leaks, ensuring that the engine operates smoothly without any loss of pressure or performance.

Engine Models QSW/QSV82, QSW27, and QSW36

The O-Ring Seal 3336210 is also suitable for the QSW/QSV82, QSW27, and QSW36 engines. These engines are designed for various applications, from industrial use to heavy-duty transportation. The seal’s design allows it to conform to the unique contours of these engines, providing a reliable barrier against leaks and contaminants.

Engine Models QSW73 and QSZ90

Lastly, the O-Ring Seal 3336210 is compatible with the QSW73 and QSZ90 engines. These engines are part of Cummins’ extensive range, offering robust performance and reliability. The seal fits these engines with precision, ensuring that they maintain their operational efficiency and longevity.

Role of Part 3336210 O-Ring Seal in Engine Systems

This part is instrumental in maintaining the integrity and efficiency of various engine systems by providing essential sealing functions. In the Connection Assembly Flywheel, it ensures that there are no leaks between the flywheel and its housing, which is vital for the smooth operation of the engine.

Within the Cooler and Engine Oil systems, the O-Ring Seal plays a significant role in preventing oil leaks. This is particularly important in the Engine Oil Assembly Cooler and Oil Cooler Subassembly, where maintaining oil pressure and temperature is essential for engine performance and longevity.

In the Drive and Front Gear Train Accessory, the seal helps in keeping the lubricants contained, which is necessary for reducing friction and wear on moving parts.

The Engine Assembly Sensor and Engine Control System rely on the O-Ring Seal to ensure that sensor readings are accurate by preventing any contaminants from entering the system through leaks.

For the Gear Assembly Housing and Housing components, the seal is used to maintain the structural integrity and prevent any fluid leakage that could compromise the housing’s function.

In the Lubricating Oil Assembly and Lubricating Oil Pressure Assembly, the O-Ring Seal is critical for maintaining the correct oil pressure, which is necessary for the proper lubrication of engine components.

The Oil Assembly Cooler, Oil Cooler, and Oil Cooler Assembly Housing all depend on the seal to ensure efficient cooling of the oil, which is paramount for engine reliability.

The Oil Pressure Assembly Lubricating and Oil Sensor Assembly utilize the seal to ensure that oil pressure readings are consistent and accurate, which is important for engine monitoring systems.

In the Plumbing systems, such as the Flywheel Housing and Oil Cooler Water, the O-Ring Seal is used to prevent leaks in the fluid pathways, ensuring that the engine receives the necessary lubrication and cooling.

The Pressure Assembly Lubricating Oil and Water Assembly Tube also benefit from the seal, as it helps in maintaining the pressure and flow of lubricants and coolants, respectively.

Lastly, in the Water Transfer Assembly Tube, the O-Ring Seal ensures that there are no leaks in the coolant system, which is essential for maintaining the engine’s operating temperature.

Conclusion

The Cummins 3336210 O-Ring Seal is a vital component in the maintenance and operation of commercial truck engines. Its role in providing reliable seals across various engine systems ensures the efficiency, performance, and longevity of these systems. Proper installation, maintenance, and understanding of its compatibility with different engine models are key to leveraging the full benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.