This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3336212 O-Ring Seal is a component designed for use in commercial trucks. It serves to create reliable seals in various mechanical systems, ensuring the efficient operation of the vehicle. This seal is integral to maintaining the integrity of fluid systems within the truck, preventing leaks and ensuring that systems operate under the correct pressure 1.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket with a circular cross-section, designed to create a seal between two or more parts. It functions by being compressed within a groove, forming a barrier that prevents the passage of fluids or gases. O-Rings are widely used in mechanical systems due to their simplicity, effectiveness, and versatility in creating seals in a variety of applications 2.

Purpose of the 3336212 O-Ring Seal in Truck Operations

This Cummins part plays a specific role in the operation of commercial trucks by ensuring the integrity of seals in various systems. It is commonly applied in areas where fluid dynamics are critical, such as in the engine, transmission, and hydraulic systems. By maintaining these seals, the O-Ring contributes to the overall efficiency and reliability of the truck’s mechanical systems.

Key Features of the 3336212 O-Ring Seal

The design and material characteristics of this part are tailored to meet the demanding conditions of commercial truck operations. It is made from materials that offer durability and resistance to a range of chemicals and temperatures. This ensures that the seal can withstand the harsh environments typical of truck operations, providing a reliable fit within the truck’s mechanical systems.

Benefits of Using the 3336212 O-Ring Seal

Utilizing this O-Ring Seal offers several advantages, including improved system reliability, reduced maintenance needs, and enhanced performance of the truck’s components. Its design and material properties contribute to a longer service life, minimizing the frequency of replacements and reducing downtime. Additionally, the seal’s effectiveness in preventing leaks helps maintain the efficiency of the truck’s systems.

Installation and Replacement Guidelines

Proper installation or replacement of this Cummins part involves several steps to ensure a secure fit and function. It is important to use the necessary tools and follow specific procedures to avoid damage to the seal or the surrounding components. Careful handling and correct placement within the designated groove are crucial for the seal to perform its intended function effectively.

Troubleshooting Common Issues

Common problems associated with O-Ring Seals, such as leaks or wear, can often be traced back to installation errors or environmental factors. Diagnosing these issues involves inspecting the seal for signs of damage or improper seating. Resolving these problems may require replacing the seal or addressing external factors that contribute to its degradation.

Maintenance Tips

Regular maintenance practices can help prolong the life of this Cummins part. This includes adhering to inspection schedules and being aware of conditions that may necessitate early replacement. Keeping the seal and its surrounding components clean and free from contaminants can also contribute to its longevity and effectiveness.

Cummins: A Brief Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its commitment to quality and innovation. The company offers a wide range of products, including engines, filtration systems, and aftermarket parts, all designed to meet the rigorous demands of commercial vehicle operations. Cummins’ reputation for reliability and performance is built on a history of delivering high-quality components and solutions to the industry.

Compatibility with Cummins Engines

This O-Ring Seal is designed to fit seamlessly within a range of Cummins engines. It is crucial for maintaining the integrity of various engine components by preventing leaks and ensuring a tight seal where necessary.

QSV81G and QSV91G Engines

This part is compatible with both the QSV81G and QSV91G engines. These engines are part of Cummins’ QSV series, known for their reliability and efficiency in various applications. The seal fits into specific areas of these engines, ensuring that critical components remain sealed and operational.

QSW/QSV82 Engines

For the QSW/QSV82 engines, this Cummins part is engineered to fit precisely within the engine’s design. This compatibility ensures that the seal performs optimally, maintaining the engine’s performance and longevity.

QSW27 and QSW36 Engines

This O-Ring Seal is also suitable for the QSW27 and QSW36 engines. These engines are part of Cummins’ QSW series, which is designed for heavy-duty applications. The seal’s design allows it to fit into the specific requirements of these engines, ensuring that they operate efficiently and reliably.

QSW73 Engines

In the QSW73 engines, this Cummins part plays a vital role in maintaining the engine’s integrity. This seal is designed to fit into the engine’s components, providing a reliable barrier against leaks and ensuring that the engine functions as intended.

QSZ90 Engines

Finally, this O-Ring Seal is compatible with the QSZ90 engines. This seal is engineered to fit into the QSZ90’s design, ensuring that it performs optimally and maintains the engine’s efficiency and reliability.

Role of Part 3336212 O-Ring Seal in Engine Systems

This O-Ring Seal is integral to the reliable operation of various engine components. It ensures the integrity of seals across multiple assemblies, preventing leaks and maintaining system efficiency.

Fuel System Components

In the fuel pump and fuel pump assembly cover, the O-Ring Seal is employed to create a tight seal, preventing fuel leakage. This is particularly important in the fuel injector assembly cover and fuel injector pump assembly cover, where precise fuel delivery is essential for engine performance. The seal ensures that fuel is delivered efficiently without any loss, contributing to the overall fuel efficiency of the engine.

Exhaust System Components

Within the exhaust assembly and exhaust manifold, the O-Ring Seal plays a significant role in sealing connections, particularly in the exhaust manifold manifold. This prevents exhaust gases from escaping, which is vital for maintaining the engine’s exhaust efficiency and reducing emissions. The seal is also used in the hotbox assembly and hotbox assy to ensure that high-temperature gases are contained within the system, protecting other engine components from excessive heat.

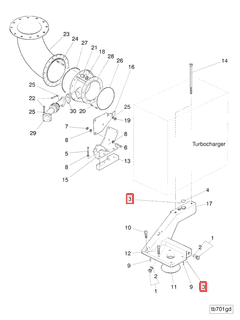

Turbocharger and Plumbing Components

In the turbocharger and plumbing turbocharger assembly, the O-Ring Seal is utilized to maintain the integrity of the seals in the turbocharger assembly arrangement and turbocharger assembly support. This is essential for the efficient operation of the turbocharger, ensuring that pressurized air is delivered to the engine without any loss of pressure. The seal is also critical in the plumbing systems, where it prevents leaks in fluid transfer lines, maintaining the efficiency of fluid systems within the engine.

Manifold and Cover Assemblies

The O-Ring Seal is extensively used in various manifold and cover assemblies, including the cover assy and manifold, exhaust. These seals are vital for preventing leaks in these components, ensuring that the engine operates efficiently and safely. The seal is also used in the hotbox and cover components to maintain the integrity of these assemblies under high-temperature conditions.

General Application

Across all these components, the O-Ring Seal (part 3336212) ensures that connections remain tight and secure, preventing leaks and maintaining the efficiency of the engine systems. Its application is widespread, reflecting its importance in the reliable operation of engine components.

Conclusion

The Cummins 3336212 O-Ring Seal is a critical component in the operation of commercial trucks, ensuring the integrity of various mechanical systems. Its design and material properties contribute to the reliability and efficiency of the truck’s components, making it an essential part for maintaining the performance of commercial vehicles.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.