This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3336214 O-Ring Seal is a component designed to ensure the integrity of fluid systems within commercial trucks. Its role is to provide a reliable seal in various applications, contributing to the efficient operation of the vehicle. Understanding its purpose and significance helps in maintaining the overall performance and longevity of the truck 1.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket that forms a seal by being squeezed in a groove. It functions by creating a barrier that prevents the leakage of fluids and gases. O-Ring Seals are widely used in mechanical systems due to their simplicity, effectiveness, and versatility. They are commonly found in hydraulic systems, fuel systems, and engine components where sealing is required 2.

Purpose of the 3336214 O-Ring Seal

This part plays a specific role in the operation of a truck by ensuring that fluid systems remain sealed. It is typically located in areas where fluid transfer occurs, such as fuel injectors or hydraulic systems. Its function is to maintain the pressure and prevent leaks, which is vital for the proper operation of these systems 3.

Key Features

The 3336214 O-Ring Seal is characterized by several key features that make it suitable for heavy-duty applications. It is made from durable materials that can withstand high pressures and temperatures. The design of the seal ensures that it can conform to the surfaces it contacts, providing a tight and reliable seal. Additionally, its material composition allows it to resist various chemicals and environmental conditions, enhancing its durability 4.

Benefits of Using the 3336214 O-Ring Seal

Using this Cummins part offers several advantages. It provides improved sealing efficiency, which helps in maintaining system pressure and preventing leaks. The seal’s longevity ensures that it can withstand the rigors of heavy-duty use, reducing the need for frequent replacements. Furthermore, its resistance to various operating conditions makes it a reliable choice for commercial trucks 1.

Installation and Maintenance

Proper installation of the 3336214 O-Ring Seal is crucial for its effectiveness. It should be installed in a clean, lubricated groove to ensure a proper fit. Routine maintenance practices include checking for signs of wear or damage and replacing the seal as needed. Regular inspections can help in identifying potential issues before they lead to system failures 2.

Troubleshooting Common Issues

Common problems associated with O-Ring Seals include leaks and wear. If a leak is detected, it may indicate that the seal has failed or is not properly installed. Wear can occur due to prolonged use or exposure to harsh conditions. Troubleshooting steps include inspecting the seal for damage, ensuring proper installation, and replacing the seal if necessary 3.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company offers a wide range of products designed to meet the needs of various applications, ensuring reliable performance and efficiency.

Cummins O-Ring Seal 3336214 Compatibility with Engine Models

This O-Ring Seal is designed to fit seamlessly within various engine models, ensuring optimal sealing and performance. It is engineered to meet the stringent requirements of the engines it supports, providing a reliable barrier against leaks and contaminants.

QSV81G, QSW/QSV82, and QSW27 Engines

This part is compatible with the QSV81G, QSW/QSV82, and QSW27 engines. These engines benefit from the precise fit and durability of the O-Ring Seal, which helps maintain system integrity and efficiency. The seal’s material and design ensure it can withstand the operational stresses of these engines, providing long-lasting performance.

QSW36 and QSW73 Engines

Similarly, the QSW36 and QSW73 engines are designed to work effectively with the O-Ring Seal 3336214. This compatibility is crucial for maintaining the operational standards of these engines, as the seal helps to prevent leaks and maintain pressure within the system. The O-Ring Seal’s fit and function are tailored to the specific needs of these engines, ensuring they operate smoothly and efficiently.

QSZ90 Engine

The QSZ90 engine also integrates the O-Ring Seal 3336214 as part of its sealing system. This engine relies on the seal’s ability to create a tight, reliable barrier, which is essential for its performance and longevity. The O-Ring Seal’s design and material properties make it an ideal choice for the QSZ90 engine, ensuring that it can handle the demands of its operational environment.

By ensuring compatibility with these engines, the O-Ring Seal 3336214 plays a critical role in maintaining the overall performance and reliability of the engines it supports.

Role of Part 3336214 O-Ring Seal in Engine Systems

This part is integral to maintaining the integrity and efficiency of various engine systems. Its application spans across multiple components, ensuring that fluids and gases are contained within their designated pathways, thereby preventing leaks and maintaining system pressure.

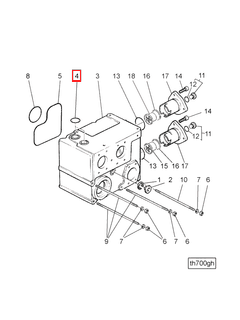

Accessory Assembly Support and Aid

In the accessory assembly support and aid components, the O-Ring Seal ensures that any fluid or gas passages are sealed effectively. This is particularly important in systems where precise fluid dynamics are required to support engine accessories.

Coolant Heater Starting and Assembly Housing Gear

For the coolant heater starting system and the assembly housing gear, the O-Ring Seal plays a significant role in preventing coolant leaks. This ensures that the heating system operates efficiently, providing the necessary warmth to facilitate easier engine starts in cold conditions.

Assembly Preheater and Camshaft Systems

In the assembly preheater and camshaft systems, the O-Ring Seal is used to maintain the integrity of fluid passages. This is essential for the preheater to function correctly, ensuring that engine components reach optimal operating temperatures swiftly. Similarly, in camshaft systems, it helps in sealing lubrication pathways, ensuring smooth operation of the cam and associated components.

Fuel System Components

Across various fuel system components such as the fuel assembly connection, fuel assembly plumbing, fuel injection assembly pump, and fuel injection pump, the O-Ring Seal is vital. It ensures that fuel lines remain leak-free, maintaining the correct fuel pressure and delivery to the engine. This is fundamental for the efficient combustion process and overall engine performance.

Gear Assembly Housing and Mounting

In the gear assembly housing and gear mounting housing, the O-Ring Seal helps in sealing lubrication points. This is important for reducing friction and wear between moving parts, ensuring longevity and reliable operation of the gear systems.

Heat Exchanger and Thermostat Housing

For the heat assembly exchanger and thermostat assembly housing, the O-Ring Seal is used to prevent coolant leaks. This ensures that the heat exchanger and thermostat function correctly, maintaining the engine’s optimal operating temperature.

Fuel Plumbing and Injection Systems

In the plumbing fuel assembly and fuel injection systems, the O-Ring Seal is essential for maintaining the integrity of fuel lines. This prevents fuel leaks and ensures that the fuel injection system delivers the correct amount of fuel at the right pressure, contributing to efficient combustion and engine performance.

Safety Valve Assembly

In the valve assembly safety, the O-Ring Seal is used to ensure that any pressure relief pathways are sealed correctly. This is important for the safety valve to function as intended, protecting the engine from over-pressurization.

Conclusion

Overall, the 3336214 O-Ring Seal is a fundamental component in various engine systems, ensuring that fluids and gases are contained within their intended pathways, thereby maintaining system efficiency and reliability 4.

-

Hilgers, Michael. Alternative Powertrains and Extensions to the Conventional Powertrain. Springer Nature, 2023.

↩ ↩ -

Bonnick, Allan. A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier, 2004.

↩ ↩ -

Bartz, Wilfried J. Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press, 2019.

↩ ↩ -

Lakshminarayanan, P. A., and Avinash Kumar. Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature, 2020.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.