3336217

O-Ring Seal

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3336217 O-Ring Seal is a component designed to ensure the integrity of seals in various systems within commercial trucks. Its role is significant in maintaining the efficiency and reliability of truck operations, particularly in environments where durability and resistance to harsh conditions are paramount 1.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket consisting of a toroidal piece of elastomer with a round cross-section. It functions by creating a seal between two or more parts, preventing the leakage of fluids or gases. O-Rings operate based on their ability to deform under compression, filling the gap between mating surfaces and forming a tight seal 2.

Purpose of the 3336217 O-Ring Seal in Truck Operation

This Cummins part plays a specific role in the operation of commercial trucks by ensuring the integrity of seals in various systems. It is commonly used in applications where fluid or gas containment is necessary, supporting systems such as fuel lines, hydraulic systems, and engine components. Its application ensures that these systems operate efficiently without leaks, contributing to the overall performance and safety of the vehicle 3.

Key Features of the 3336217 O-Ring Seal

This part is characterized by several key features that make it suitable for its intended applications. These include its material composition, typically a durable elastomer that offers resistance to a wide range of temperatures and chemicals. Its size is designed to fit specific applications, ensuring a proper seal. Additionally, it may possess unique attributes such as enhanced flexibility or resistance to compression set, which contribute to its effectiveness in demanding environments 4.

Benefits of Using the 3336217 O-Ring Seal

Utilizing this O-Ring Seal offers several advantages. It provides improved sealing efficiency, ensuring that systems remain leak-free under various operating conditions. Its durability allows it to withstand the rigors of commercial truck operation, while its resistance to environmental factors such as temperature extremes and chemical exposure ensures long-term reliability.

Installation and Maintenance Guidelines

Proper installation of the 3336217 O-Ring Seal involves preparing the mating surfaces to ensure they are clean and free of debris. It is important to follow torque specifications during installation to avoid over-tightening, which can damage the seal. Regular maintenance, including inspection for wear or damage, is recommended to ensure the longevity and optimal performance of the seal.

Troubleshooting Common Issues

Common issues associated with O-Ring Seals, such as leaks or failures, can often be traced to improper installation, wear and tear, or exposure to incompatible fluids. Troubleshooting steps may include inspecting the seal for damage, ensuring proper installation techniques are followed, and verifying compatibility with the system’s fluids and operating conditions.

Compatibility and Application

This Cummins part is designed for use within Cummins engines and other commercial truck components, demonstrating its versatility and widespread application. Its compatibility with various systems underscores its importance in maintaining the efficiency and reliability of commercial trucks.

Manufacturer Information - Cummins

Cummins is a reputable manufacturer in the commercial truck industry, known for its commitment to quality and innovation. They offer a wide range of products designed to enhance the performance and reliability of commercial vehicles, including the 3336217 O-Ring Seal. Cummins’ reputation is built on their dedication to producing durable, high-quality components that meet the demanding requirements of commercial truck operations.

Cummins O-Ring Seal 3336217 Compatibility with Engine Models

The Cummins O-Ring Seal part number 3336217 is designed to fit seamlessly within a variety of engine models, ensuring optimal sealing performance and reliability. This O-Ring Seal is engineered to meet the stringent requirements of high-performance engines, providing a critical barrier against leaks and maintaining system integrity.

QSV81G, QSV91G, QSW/QSV82, QSW27, QSW36, QSW73, and QSZ90

The O-Ring Seal 3336217 is compatible with the following engine models:

- QSV81G

- QSV91G

- QSW/QSV82

- QSW27

- QSW36

- QSW73

- QSZ90

These engines benefit from the precise fit and durability of the O-Ring Seal, ensuring that the seal performs effectively under various operating conditions. The seal’s design allows it to conform to the specific contours of the engine components, providing a tight seal that prevents fluid and gas leaks.

QSV91-G4 CM558/CM700 V102

The O-Ring Seal 3336217 is also suitable for the QSV91-G4 CM558/CM700 V102 engine. This particular engine model, with its advanced features and high-performance capabilities, requires a reliable sealing solution to maintain its operational efficiency. The O-Ring Seal 3336217 is engineered to meet these demands, providing a consistent and reliable seal that enhances the engine’s overall performance and longevity.

By integrating the O-Ring Seal 3336217 into these engine models, users can expect improved sealing performance, reduced maintenance needs, and enhanced reliability, ensuring that their engines operate at peak efficiency.

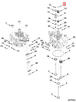

Role of Part 3336217 O-Ring Seal in Engine Systems

This part is integral to the functionality and efficiency of various engine systems. It ensures the integrity of fluid pathways and the prevention of leaks, thereby maintaining optimal performance across different components.

Fuel System Integration

In the fuel system, the O-Ring Seal is employed in the fuel filter, fuel assembly filter, and fuel assembly prefilter to create a secure seal that prevents fuel leakage. It is also vital in the fuel assembly pump and fuel block connection, ensuring that fuel is delivered consistently without any loss. Additionally, in the fuel shut-off assembly valve and fuel sub-assembly plumbing, the seal maintains the pressure integrity required for efficient fuel delivery.

Oil System Applications

Within the oil system, the O-Ring Seal is used in the oil assembly pan and oil sub-assembly pan to prevent oil leaks, ensuring that the lubrication system remains effective. This seal is also crucial in the pan, oil connections, maintaining the necessary oil pressure for engine components.

Cylinder and Head Assembly

In the cylinder assembly head and cylinder head, the O-Ring Seal is utilized to ensure that there are no leaks between the head and the block, preserving combustion efficiency. It is also found in the cylinder head kit and single head gasket set, contributing to the overall seal integrity of the engine’s upper end.

Turbocharger and Plumbing

The O-Ring Seal plays a role in the plumbing, turbocharger system by ensuring that the high-pressure air pathways remain sealed. In the plumbing, fuel tube and plumbing, fuel systems, it prevents leaks in the fuel lines, maintaining consistent fuel pressure and flow.

Additional Components

The seal is also used in the camshaft and connecting rod and piston assemblies to ensure that any fluid pathways associated with these components are securely sealed. This helps in maintaining the performance and longevity of these critical engine parts.

Conclusion

The Cummins 3336217 O-Ring Seal is a vital component in ensuring the efficiency and reliability of commercial truck operations. Its design and features make it suitable for a wide range of applications, from fuel and oil systems to cylinder heads and turbochargers. Proper installation and maintenance are crucial for maximizing its performance and longevity, contributing to the overall safety and efficiency of the vehicle.

-

Atkins, Richard D. An Introduction to Engine Testing and Development. SAE International, 2009.

↩ -

Zhan, Quansheng, Eben, Shengbo, and Deng, Li Kun. Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning, 2018.

↩ -

Gilles, Tim. Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning, 2020.

↩ -

Singh, D. K. Dictionary of Mechanical Engineering. Springer Nature, 2024.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.