This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3336218 O-Ring Seal is a critical component in commercial truck maintenance and operation, designed to enhance the efficiency and reliability of the vehicle. Understanding its function and importance is essential for maintaining high performance standards in commercial trucking.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a gasket that forms a seal by being compressed within a groove, preventing the leakage of fluids or gases in mechanical systems. Its simplicity, effectiveness, and versatility make it widely used in automotive and industrial machinery 1.

Purpose of the 3336218 O-Ring Seal in Truck Operation

This Cummins part ensures the integrity of seals in specific systems or components where fluid or gas containment is necessary. It contributes to the efficient operation of the truck by preventing leaks and maintaining system pressure 2.

Key Features of the 3336218 O-Ring Seal

The 3336218 O-Ring Seal is characterized by its durable elastomer material and precise dimensions tailored to fit specific grooves. Its cross-sectional shape enhances performance and durability, allowing it to withstand various operational stresses and environmental conditions 3.

Benefits of Using the 3336218 O-Ring Seal

This part offers improved sealing efficiency, contributing to the overall performance of the truck’s systems. Its longevity and resistance to environmental factors, such as temperature extremes and chemical exposure, make it a reliable component for commercial truck applications.

Installation Considerations

Proper installation of the 3336218 O-Ring Seal involves ensuring the groove is clean, using the correct lubrication, and avoiding damage to the O-Ring. Following these guidelines ensures optimal performance and longevity.

Troubleshooting Common Issues

Common issues with O-Ring Seals, such as leaks or failures, can often be traced back to installation errors, material degradation, or operational stresses. Diagnosing these issues involves inspecting the seal and its environment for signs of wear, damage, or misalignment.

Maintenance Tips

Regular maintenance of the 3336218 O-Ring Seal includes inspection intervals to check for signs of wear or damage, cleaning procedures to remove contaminants, and considering replacement when signs of degradation are observed. These practices help maintain the seal’s effectiveness and the truck’s operational efficiency.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. The development and use of the 3336218 O-Ring Seal are part of Cummins’ commitment to quality and excellence in the automotive sector.

Role of 3336218 O-Ring Seal in Engine Systems

The 3336218 O-Ring Seal is integral to maintaining the integrity and efficiency of various engine systems. It ensures that fluids and gases are contained within their designated pathways, preventing leaks and maintaining system pressure.

Coolant and Heater Systems

In the coolant heater starting arrangement, the O-Ring Seal ensures that the coolant remains within the system, providing consistent heating to the engine during startup.

Engine Oil Systems

Within the engine oil cooler and oil cooler assembly, the O-Ring Seal keeps the oil contained as it circulates through the cooler, ensuring that the oil maintains its lubricating properties.

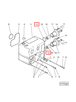

Flywheel and Gear Assemblies

In the flywheel assembly housing and gear assembly housing, the O-Ring Seal helps in sealing the interfaces where different components meet, maintaining the structural integrity of these assemblies.

Thermostat Housing and Assemblies

The O-Ring Seal is used in various thermostat-related components to ensure that the coolant flow is regulated effectively, allowing the engine to reach and maintain its operating temperature.

Lubricating Oil Module Assembly

In the lubricating oil module assembly, the O-Ring Seal ensures that the oil pathways remain sealed, preventing any leakage that could lead to insufficient lubrication.

Water Manifold and Transfer Assemblies

The water assembly manifold and water transfer assembly tube rely on the O-Ring Seal to maintain the integrity of the water pathways, ensuring efficient coolant circulation.

Oil Cooler and Plumbing

In the oilcooler subassy and plumbing oil cooler water, the O-Ring Seal ensures that the oil and water pathways remain separate, preventing any cross-contamination.

Thermostat Equipment Housing

The thermostat equip housing utilizes the O-Ring Seal to ensure that the thermostat operates within a sealed environment, important for accurate temperature regulation.

Additional Applications

The O-Ring Seal is also employed in the oil assembly cooler, oil cooler assembly housing, thermostat assembly holder, and thermostat cover to maintain the seals in these components, ensuring they function as intended without leaks or inefficiencies.

Conclusion

The 3336218 O-Ring Seal plays a vital role in the operation and maintenance of commercial trucks by ensuring the integrity of seals in various engine systems. Its design, durability, and resistance to environmental factors make it a reliable component for enhancing the efficiency and reliability of commercial vehicles.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.