This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3336232 O-Ring Seal, manufactured by Cummins, is a critical component in the commercial truck industry. This part ensures the integrity and efficiency of various systems within commercial trucks through effective sealing.

Basic Concepts of O-Ring Seals

O-Ring Seals are circular rings, typically made from elastomers, that create a seal when compressed within a groove. They function by filling the space between mating parts, preventing the passage of fluids and gases. O-Rings are widely used in mechanical systems due to their simplicity, effectiveness, and versatility in creating seals in various applications 1.

Purpose of the 3336232 O-Ring Seal in Truck Operations

The 3336232 O-Ring Seal plays a specific role in the operation of commercial trucks by ensuring the sealing integrity of certain systems or components. It is associated with systems where fluid or gas containment is necessary to maintain system efficiency and prevent leaks. The seal helps in maintaining the pressure and purity of the fluids or gases within the system, contributing to the overall performance and reliability of the truck 2.

Key Features of the 3336232 O-Ring Seal

The 3336232 O-Ring Seal is characterized by its design and material properties, which include durability, resistance to specific chemicals, and a suitable temperature range for operation. These features make it well-suited for the demanding environments found in commercial truck applications, ensuring long-lasting performance and reliability 3.

Benefits of Using the 3336232 O-Ring Seal

Utilizing the 3336232 O-Ring Seal offers several advantages, such as enhanced system efficiency, increased longevity of the sealed components, and improved reliability in sealing applications. Its design and material properties contribute to these benefits, making it a valuable component in commercial truck maintenance and operation 4.

Installation Considerations

Proper installation of the 3336232 O-Ring Seal is vital for ensuring optimal performance and longevity. Guidelines and best practices for installation include ensuring the groove is clean and free of debris, using the correct lubrication during installation, and avoiding over-stretching the O-Ring. These practices help in achieving a secure and effective seal.

Troubleshooting Common Issues

Common problems associated with O-Ring Seals, such as leaks or failures, can often be traced back to installation errors, environmental factors, or material degradation. Troubleshooting steps may involve inspecting the seal and groove for damage, checking for proper installation, and assessing the environmental conditions to which the seal is exposed.

Maintenance Tips

Regular maintenance of the 3336232 O-Ring Seal includes periodic inspection for signs of wear or damage, cleaning the seal and groove as necessary, and replacing the seal according to the manufacturer’s recommendations or when signs of degradation are observed. These practices help in maintaining the seal’s effectiveness and extending its service life.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction, making it a trusted partner for commercial truck operators and maintenance professionals.

Cummins O-Ring Seal 3336232 Compatibility with Engine Models

The Cummins O-Ring Seal part number 3336232 is designed to fit seamlessly within the engine systems of the QSW27 and QSW36 engines. This seal is crucial for maintaining the integrity of the engine’s sealing mechanisms, ensuring that there are no leaks and that the engine operates efficiently.

For the QSW27 and QSW36 engines, the O-Ring Seal 3336232 is engineered to provide a reliable seal in various critical areas. Its placement is vital for preventing fluid and gas leaks, which can compromise engine performance and longevity. The seal’s design ensures it can withstand the high temperatures and pressures typical of these engine environments.

In the case of the QSZ90 engine, the O-Ring Seal 3336232 also plays a pivotal role. Given the advanced technology and design of the QSZ90, this seal is tailored to fit precisely within the engine’s specific sealing requirements. Its compatibility with the QSZ90 ensures that the engine maintains optimal sealing, contributing to its overall efficiency and reliability.

The O-Ring Seal 3336232’s compatibility with these engines underscores its importance in maintaining the engine’s operational integrity. Its design and material properties make it an essential component for ensuring that the engines function as intended, without the risk of leaks or other sealing-related issues.

Role of Part 3336232 O-Ring Seal in Engine Systems

The 3336232 O-Ring Seal is an essential component in maintaining the integrity and efficiency of various engine systems. Its application spans across multiple assemblies and sub-assemblies, ensuring that fluids and gases are contained within their designated pathways, thereby preventing leaks and maintaining system pressure.

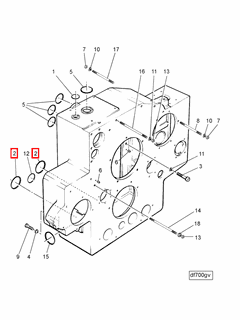

Assembly Housing and Gear Components

In the assembly housing gear and gear assembly housing, the O-Ring Seal is utilized to create a tight seal between moving parts and stationary housings. This ensures that lubricants, such as engine oil, remain within the system, reducing friction and wear on gears.

Cylinder and Block Assemblies

Within the cylinder and block, as well as the cylinder assembly block, cylinder sensor assembly block, and cylinder sub-assembly block, the O-Ring Seal plays a significant role in sealing the interfaces between components. This is particularly important in high-pressure environments where even minor leaks can lead to performance issues.

Cooler and Engine Oil Systems

The cooler and engine oil systems benefit from the O-Ring Seal in the engine oil assembly cooler. Here, it ensures that the cooling fluid circulates efficiently without leakage, maintaining optimal engine temperature and prolonging the life of engine components.

Flywheel and Housing Assemblies

In the flywheel assembly housing and gear mounting housing, the O-Ring Seal is critical for sealing the interfaces where the flywheel meets the housing. This prevents any lubricants from escaping, which is vital for the smooth operation of the flywheel and connected components.

Pump Drive and Thermostat Housings

The housing pump drive and various thermostat housings (thermostat assembly housing, thermostat mounting housing) rely on the O-Ring Seal to maintain the integrity of the cooling system. By sealing the connections between the thermostat and the housing, it ensures that the coolant flows correctly through the engine, regulating temperature effectively.

Manifold and Water Systems

In the manifold, water and water assembly manifold, the O-Ring Seal is used to ensure that water or other coolants are properly contained within the manifold. This is essential for consistent coolant distribution throughout the engine, which is crucial for thermal management.

Additional Applications

The O-Ring Seal is also employed in the seal free end mtg, manifold water, and pump drive assembly housing. In these applications, it ensures that any fluids or gases are correctly sealed, preventing leaks that could lead to system inefficiency or failure.

Conclusion

Overall, the 3336232 O-Ring Seal is a versatile component that enhances the reliability and performance of various engine systems by ensuring proper sealing and containment of fluids and gases. Its compatibility with specific Cummins engine models and its role in critical engine assemblies underscore its importance in maintaining engine efficiency and reliability.

-

Robert Bosch GmbH. (2007). Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg.

↩ -

Konrad Reif Ed. (2015). Gasoline Engine Management Systems and Components. Springer Vieweg.

↩ -

Wilfried J Bartz. (2019). Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press.

↩ -

Sean Bennett, Ian Andrew Norman. (2011). Heavy Duty Truck Systems Fifth Edition. Delmar Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.