3348961

O-Ring Seal

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3348961 O-Ring Seal is a vital component in commercial trucks, designed to ensure the integrity of fluid and gas pathways by providing a reliable seal in various systems. This part is essential for maintaining the efficiency and performance of truck systems, preventing leaks, and ensuring proper system function 1.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket that creates a seal by being compressed within a groove. It operates based on the principle of elastomeric deformation, where the ring’s material deforms to fill the space between two surfaces, creating a barrier to fluid or gas flow. O-Rings are widely used in mechanical systems for their simplicity, effectiveness, and versatility 2.

Purpose of the Cummins 3348961 O-Ring Seal

The Cummins 3348961 O-Ring Seal is specifically designed for use in commercial trucks, where it is utilized in systems requiring fluid or gas sealing, such as the engine, transmission, or hydraulic systems. By ensuring a tight seal, it helps maintain system pressure, prevent leaks, and contribute to the overall efficiency and reliability of the truck’s operation 3.

Key Features

This Cummins part is characterized by several key features that enhance its performance. It is made from high-quality elastomeric materials, chosen for their durability and resistance to various chemicals and operating conditions. The design specifications of this O-Ring, including its size and cross-sectional area, are tailored to meet the specific requirements of its application, ensuring optimal sealing capabilities 4.

Benefits

Using the Cummins 3348961 O-Ring Seal offers several advantages. It contributes to improved system efficiency by ensuring that fluids and gases remain within their intended pathways. The seal’s durability and reliability help extend the lifespan of the systems it is part of, reducing the need for frequent replacements. Additionally, its effective sealing capabilities help maintain system performance and reliability over time 1.

Installation Considerations

Proper installation of the Cummins 3348961 O-Ring Seal is vital for its performance and longevity. It should be installed in a clean, undamaged groove to ensure a proper seal. Care should be taken to avoid damaging the O-Ring during installation, as this can compromise its sealing ability. Following manufacturer guidelines for installation can help ensure optimal performance and longevity of the seal 2.

Troubleshooting Common Issues

Common issues with O-Ring Seals include leaks, which can occur due to wear, damage, or improper installation. Troubleshooting these issues involves inspecting the seal and its groove for signs of wear or damage, ensuring the seal is correctly sized and installed, and checking for any external factors that may be affecting its performance. Addressing these issues promptly can help maintain system efficiency and prevent further damage 3.

Maintenance Tips

Regular maintenance of the Cummins 3348961 O-Ring Seal can help prolong its lifespan and ensure continued efficient operation. This includes periodic inspection for signs of wear or damage, cleaning the seal and its groove to remove any contaminants, and replacing the seal as needed. Adhering to these maintenance practices can help maintain the seal’s effectiveness and contribute to the overall reliability of the truck’s systems 4.

Replacement Procedures

Replacing a worn or damaged Cummins 3348961 O-Ring Seal involves several steps. First, the system must be drained of any fluids to prevent contamination. The old seal is then removed, taking care not to damage the groove. The new seal is installed according to manufacturer guidelines, ensuring it is properly seated in the groove. Finally, the system is refilled with fluid, and its operation is tested to ensure the new seal is functioning correctly 1.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and commitment to quality, Cummins plays a significant role in the commercial truck industry. Its products, including the Cummins 3348961 O-Ring Seal, are designed to meet the demanding requirements of commercial applications, ensuring reliability and performance in various operating conditions 2.

Compatibility with Cummins Engines

The O-Ring Seal part number 3348961 is compatible with several Cummins engine models, including the QSB6.7 CM850 (CM2850), QSK19 CM850 MCRS, QSB7 CM2880 B117, QSK45 CM500, QSK60 CM500, QSK60 CM850 MCRS, QSK78 CM500, X15 CM2350 X116B, and X15 CM2450 X134B. This seal is designed to fit seamlessly within the engine architecture of these models, providing a reliable barrier against leaks and maintaining system pressure 3.

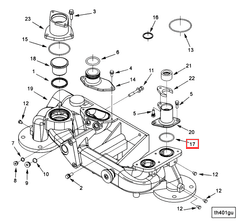

Role in Engine Systems

The Cummins 3348961 O-Ring Seal plays a crucial role in various engine systems. In the arrangement of engine components, this seal ensures tight and secure connections between parts, preventing leaks that could compromise performance. It is used in the Exhaust Recirculation (EGR) System, filters (Fuel Filter and Full Flow Oil Filter), Lubricating Oil System, Thermostat Housing, Inlet Manifold, Lube Oil Filter Head, Lubricating Oil Filter Head, plumbing applications within the engine, and recirculation and exhaust systems. Its role in these systems ensures that the engine operates efficiently and reliably under demanding conditions 4.

Conclusion

The Cummins 3348961 O-Ring Seal is a critical component in maintaining the integrity and efficiency of various engine systems in commercial trucks. Its proper installation, maintenance, and replacement are essential for ensuring the reliability and performance of these systems. By understanding its key features, benefits, and role in engine systems, truck operators and maintenance professionals can ensure the longevity and efficiency of their vehicles.

-

Giles, T. (2019). Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning.

↩ ↩ ↩ -

Kershaw, J. F. (2023). SAE International’s Dictionary for Automotive Engineers. SAE International.

↩ ↩ ↩ -

Sclar, D. (2008). Auto Repair for Dummies: 2nd Edition. For Dummies.

↩ ↩ ↩ -

Hilgers, M. (2023). Alternative Powertrains and Extensions to the Conventional Powertrain. Springer Nature.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.