3393565

O-Ring Seal

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3393565 O-Ring Seal is a critical component for maintaining the integrity of fluid systems in commercial trucks. It ensures reliable sealing in various applications, contributing to the efficient operation of the vehicle. Understanding its purpose and significance is essential for maintaining the performance and longevity of truck systems.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a toroidal (ring-shaped) elastomer with a circular cross-section, used to create a seal between two or more parts. It functions by being compressed within a groove, forming a barrier that prevents the leakage of fluids or gases. O-Ring Seals are widely utilized in mechanical systems due to their simplicity, effectiveness, and versatility in sealing applications 1.

Purpose of the Cummins 3393565 O-Ring Seal

The Cummins 3393565 O-Ring Seal is specifically engineered to serve in the demanding environments of commercial trucks. It is positioned in areas where fluid systems require a robust seal to maintain pressure and prevent leaks. Its function within the truck’s system is to ensure that fluids, such as coolants or lubricants, are contained within their designated pathways, thereby supporting the overall efficiency and reliability of the truck’s operation 2.

Key Features

The Cummins 3393565 O-Ring Seal is characterized by its material composition, which is typically a durable elastomer capable of withstanding high temperatures, pressures, and a range of chemical exposures. Its design is tailored to fit precisely within the grooves of the components it seals, ensuring a snug fit that enhances its sealing capabilities. These features make it well-suited for heavy-duty applications, where reliability and performance are paramount 3.

Benefits

Utilizing the Cummins 3393565 O-Ring Seal offers several advantages, including improved sealing efficiency, which helps in maintaining system pressure and preventing leaks. Its durability ensures a longer service life, reducing the frequency of replacements. Additionally, its resistance to various operating conditions, such as extreme temperatures and chemical exposure, contributes to the overall reliability of the truck’s fluid systems 4.

Installation Considerations

Proper installation of the Cummins 3393565 O-Ring Seal is vital for its optimal performance and longevity. It should be installed in a clean, undamaged groove to ensure a proper seal. Care should be taken to avoid damaging the O-Ring during installation, as any nicks or tears can compromise its sealing ability. Following manufacturer guidelines for installation will help ensure the seal functions as intended 1.

Troubleshooting Common Issues

Common problems with O-Ring Seals include leaks, which can be caused by improper installation, damage to the O-Ring, or degradation over time. Troubleshooting steps may involve inspecting the seal for signs of wear or damage, ensuring the groove is clean and undamaged, and verifying that the O-Ring is the correct size and material for the application. Addressing these issues promptly can help maintain the integrity of the truck’s fluid systems 2.

Maintenance Tips

Regular maintenance of the Cummins 3393565 O-Ring Seal involves periodic inspection for signs of wear, damage, or degradation. Keeping the sealing surfaces clean and free of contaminants will help prolong the seal’s service life. Additionally, adhering to recommended replacement intervals can prevent unexpected failures and ensure continued reliable performance of the truck’s systems 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves commercial truck, bus, construction, agricultural, and power generation markets. Its reputation in the commercial truck industry is built on a commitment to reliability, performance, and customer satisfaction 4.

Compatibility with Cummins Engines

The O-Ring Seal part number 3393565, manufactured by Cummins, is designed to fit seamlessly within a variety of Cummins engine models. This seal is crucial for maintaining the integrity of the engine’s sealing system, ensuring that there are no leaks and that the engine operates efficiently.

QSK45 CM500 and QSK60 CM500

Both the QSK45 CM500 and QSK60 CM500 engines benefit from the O-Ring Seal 3393565. This seal is engineered to fit precisely in these engines, providing a reliable barrier against oil and other fluids. Its placement is critical in maintaining the engine’s performance and longevity.

QSK60 CM850 MCRS and QSK60G

The QSK60 CM850 MCRS and QSK60G engines also incorporate the O-Ring Seal 3393565. This seal ensures that the engine’s components remain sealed, preventing any potential leaks that could compromise the engine’s efficiency and reliability. Its design is tailored to fit these specific engine models, ensuring optimal performance.

QSK78 CM500

The QSK78 CM500 engine is another model that utilizes the O-Ring Seal 3393565. This seal is essential for maintaining the engine’s sealing integrity, ensuring that it operates smoothly and efficiently. Its precise fit is critical for the engine’s overall performance.

QSK95 CM2350 K111 and QSK95 CM2350 K113

Lastly, the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines also incorporate the O-Ring Seal 3393565. This seal is designed to fit these engines perfectly, providing a reliable seal that is crucial for the engine’s operation. Its placement is critical in ensuring that the engine maintains its performance and efficiency.

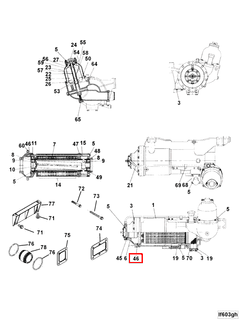

Role of Part 3393565 O-Ring Seal in Engine Systems

The 3393565 O-Ring Seal is instrumental in maintaining the integrity and efficiency of various engine systems by ensuring proper sealing in critical junctures.

- Full Flow Oil Filter: The O-Ring Seal is positioned to create a tight seal between the filter and the engine block or filter housing. This prevents oil leaks and ensures that the oil flows through the filter media without bypassing, which is essential for effective filtration and maintaining clean lubricating oil.

- Lubricating Oil Filter Housing Kit: The O-Ring Seal plays a significant role in sealing the connection points between the filter housing and the engine. This is vital for maintaining the pressure integrity of the lubricating system, ensuring that oil is delivered consistently to all moving parts without any loss.

- Lubricating Oil Filter: The O-Ring Seal is used at the base where the filter connects to the engine or filter housing. This seal is responsible for preventing oil from leaking out while allowing it to pass through the filter media for purification.

- Lubricating Oil Filter Head: The O-Ring Seal is employed to ensure a secure connection between the filter head and the filter element. This is important for maintaining the structural integrity of the filter assembly and ensuring that the oil filtration process is not compromised.

- Lubricating Oil Filter Kit: The O-Ring Seal is utilized at multiple connection points within the kit, which typically includes various components such as the filter, housing, and head. This comprehensive sealing approach is essential for the overall performance and longevity of the lubricating oil system, ensuring that the engine receives clean, pressurized oil for optimal operation.

Conclusion

The Cummins 3393565 O-Ring Seal plays a vital role in the efficient operation of commercial truck engines by ensuring reliable sealing in critical fluid systems. Its durable construction, precise fit, and compatibility with various Cummins engine models make it an essential component for maintaining engine performance and longevity. Proper installation, regular maintenance, and prompt troubleshooting of common issues are key to maximizing the benefits of this Cummins part.

-

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill, 2018.

↩ ↩ -

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines. McGraw-Hill, 2008.

↩ ↩ -

Majewski, Addy, and Hannu Jaskelainen. Diesel Emissions and Their Control: Second Edition. SAE International, 2023.

↩ ↩ -

Bennett, Sean. Modern Diesel Technology: Light Duty Diesels. Cengage Learning, 2012.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.