This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3393577 O-Ring Seal is a vital component in ensuring the integrity of seals within various systems in commercial trucks. It plays a significant role in maintaining the efficiency and reliability of truck operations by preventing leaks and ensuring proper system function.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a gasket made from a jointless ring of elastomeric material, used for sealing applications. It functions by creating a barrier that prevents the passage of fluids or gases between two surfaces. When compressed between flanges, the O-Ring deforms to fill the gap, providing a flexible and durable seal 1.

Purpose of the 3393577 O-Ring Seal in Truck Operations

The 3393577 O-Ring Seal ensures the sealing of various components and systems in commercial trucks. It is commonly applied in areas requiring fluid or gas containment, such as engine systems, fuel lines, and hydraulic systems. Its function is to maintain system pressure, prevent leaks, and protect sensitive components from contamination 2.

Key Features

The Cummins 3393577 O-Ring Seal is made from durable elastomers that can withstand high temperatures, pressures, and a range of chemical exposures. Its design specifications include precise dimensions and a smooth surface finish, which are essential for creating effective seals in heavy-duty applications 3.

Benefits of Using the 3393577 O-Ring Seal

Incorporating the 3393577 O-Ring Seal into truck maintenance and operations offers several advantages. It contributes to improved efficiency by ensuring that systems operate under the correct pressure and without leaks. Its reliability and durability enhance the longevity of sealed components, reducing the need for frequent replacements and maintenance.

Installation Considerations

Proper installation of the 3393577 O-Ring Seal is vital for its optimal performance and longevity. Guidelines for installation include ensuring the sealing surfaces are clean and free of debris, using the correct lubrication to facilitate seating, and avoiding over-tightening which can damage the O-Ring. Careful handling and installation according to manufacturer specifications are recommended to ensure effective sealing.

Troubleshooting Common Issues

Common problems associated with O-Ring Seals include leaks, which can be caused by improper installation, degradation of the O-Ring material, or incorrect sizing. Recommended solutions include inspecting the seal for signs of wear or damage, ensuring correct installation practices are followed, and replacing the O-Ring if necessary to maintain system integrity.

Maintenance Tips

Regular maintenance practices for the 3393577 O-Ring Seal include periodic inspection for signs of wear, checking for proper seating, and ensuring that the sealing surfaces remain clean and undamaged. Adhering to these practices can prolong the lifespan of the O-Ring Seal and ensure continued effective performance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry, offering a wide range of products designed to meet the demanding requirements of heavy-duty applications.

Cummins Engine O-Ring Seal 3393577 Compatibility

The O-Ring Seal part number 3393577, manufactured by Cummins, is designed to fit seamlessly within a variety of Cummins engine models. This seal is crucial for maintaining the integrity of the engine’s sealing system, ensuring that there are no leaks and that the engine operates efficiently.

QSK45 CM500 and QSK60 CM500

The O-Ring Seal 3393577 is compatible with both the QSK45 CM500 and QSK60 CM500 engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The seal ensures that the engine’s components remain properly sealed, preventing any fluid or gas leakage that could compromise engine performance.

QSK60 CM850 MCRS and QSK60G

For the QSK60 CM850 MCRS and QSK60G engines, the O-Ring Seal 3393577 provides a critical sealing function. These engines are typically used in marine and industrial applications, where durability and efficiency are paramount. The seal’s design ensures that it can withstand the demanding conditions these engines operate under, maintaining a tight seal and protecting internal components from contaminants.

QSK78 CM500

The QSK78 CM500 engine also benefits from the O-Ring Seal 3393577. This engine is often utilized in heavy-duty on-highway applications, where it needs to deliver consistent power and reliability. The seal’s precision fit ensures that the engine’s sealing system remains intact, preventing any potential leaks that could lead to performance issues.

QSK95 CM2350 K111 and QSK95 CM2350 K113

Finally, the O-Ring Seal 3393577 is compatible with the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines. These engines are designed for extreme durability and are often used in the most challenging environments. The seal’s robust construction ensures that it can handle the high pressures and temperatures these engines generate, providing a reliable seal that enhances engine performance and longevity.

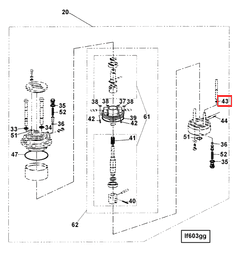

Role of Part 3393577 O-Ring Seal in Engine Systems

The 3393577 O-Ring Seal is instrumental in maintaining the integrity and efficiency of various engine systems. In the context of a Full Flow Oil Filter, this O-Ring Seal ensures a tight and secure connection between the filter and the engine block, preventing oil leaks and maintaining consistent oil pressure. This is vital for the proper lubrication of engine components, reducing wear and tear.

When integrated into a Lubricating Oil System, the O-Ring Seal plays a significant role in the Lubricating Oil Filter and Lubricating Oil Filter Head. It creates a seal that prevents oil from bypassing the filter, ensuring that contaminants are effectively removed from the oil. This enhances the longevity and performance of the engine by maintaining clean lubrication.

In the Hydraulic Kit, the O-Ring Seal is used to secure connections within the hydraulic lines and components. This ensures that hydraulic fluid is contained within the system, providing consistent pressure and performance for hydraulic actuators and controls.

For the Lubricating Oil Filter Kit, the O-Ring Seal is essential in assembling the various components of the kit. It ensures that each connection within the kit is leak-free, allowing for efficient filtration and circulation of lubricating oil throughout the engine system. This contributes to the overall reliability and efficiency of the engine by ensuring that all moving parts are properly lubricated and protected from wear.

Conclusion

The Cummins 3393577 O-Ring Seal is a critical component in maintaining the efficiency and reliability of commercial truck operations. Its role in preventing leaks, ensuring proper system function, and enhancing the longevity of sealed components makes it an indispensable part of truck maintenance and engine systems.

-

Asef, P., Padmanaban, S., & Lapthorn, A. (2022). Modern Automotive Electrical Systems. Wiley.

↩ -

Minaker, B. P. (2019). Fundamentals of Vehicle Dynamics and Modelling. John Wiley Sons.

↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.