This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3393707 O Ring Seal is a component designed for use in commercial trucks. Its purpose is to provide a reliable seal in various applications within the truck’s engine and other systems. This seal is integral to maintaining the integrity of fluid systems, preventing leaks, and ensuring the efficient operation of the truck 1.

Basic Concepts of O Ring Seals

An O Ring Seal is a type of gasket consisting of a toroidal (ring-shaped) piece of elastomer. It functions by creating a seal when compressed between two or more mating surfaces. O Ring Seals are widely used in mechanical systems to prevent the leakage of fluids and gases. They are valued for their simplicity, effectiveness, and versatility in various applications 2.

Role of the 3393707 O Ring Seal in Truck Operation

This Cummins part plays a specific role in the operation of a truck by ensuring the integrity of seals in the engine and other systems. It is typically placed in areas where fluid dynamics are critical, such as around injection nozzles, fuel lines, or coolant passages. Its function is to maintain a tight seal under pressure, thereby preventing leaks and ensuring the efficient transfer of fluids 3.

Key Features of the 3393707 O Ring Seal

The 3393707 is characterized by several key features that enhance its performance. It is made from a durable elastomer material, which provides resistance to a wide range of temperatures and chemical environments. The design of the seal ensures it can withstand high pressures without deforming, maintaining its sealing properties over time. Additionally, the material composition of the seal contributes to its longevity and reliability in demanding applications.

Benefits of Using the 3393707 O Ring Seal

Using this part offers several benefits. It provides improved sealing efficiency, which is crucial for maintaining the performance of fluid systems in a truck. The seal’s durability ensures it can withstand the rigors of commercial truck operation, leading to longer service intervals. Furthermore, its resistance to various operating conditions, including extreme temperatures and exposure to chemicals, enhances its reliability and effectiveness.

Installation and Maintenance

Proper installation of the 3393707 is crucial for its effectiveness. It should be installed in a clean, dry environment to prevent contamination that could compromise the seal. During maintenance, it is important to inspect the seal for signs of wear or damage and replace it as necessary to ensure continued sealing efficiency. Regular checks and replacements can help maintain the integrity of the truck’s fluid systems.

Troubleshooting Common Issues

Common problems associated with O Ring Seals include leaks, which can occur due to wear, damage, or improper installation. Troubleshooting steps include inspecting the seal for physical damage, ensuring it is correctly installed, and checking for contamination or debris that could affect its performance. Addressing these issues promptly can help maintain the efficiency and reliability of the truck’s systems.

Manufacturer: Cummins

Cummins is a renowned manufacturer in the automotive and heavy-duty truck industry, known for its commitment to quality and innovation. With a history of producing reliable and high-performance components, Cummins has established a reputation for excellence. The company’s focus on research and development ensures that its products, including the 3393707, meet the demanding requirements of commercial truck applications.

Conclusion

The Cummins 3393707 O Ring Seal is a vital component in the operation of commercial trucks, ensuring the integrity of fluid systems and preventing leaks. Its durable construction, resistance to various operating conditions, and ease of maintenance make it a reliable choice for truck operators. Proper installation and regular maintenance are key to maximizing the effectiveness of this part, contributing to the overall efficiency and reliability of the truck’s systems.

-

Quansheng Zhan, Shengbo Eben, Li Kun Deng. Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning, 2018.

↩ -

Giancarlo Genta and Lorenzo Morello. The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer, 2019.

↩ -

P. A. Lakshminarayanan and Nagaraj S. Nayak. Critical Component Wear in Heavy Duty Engines. John Wiley & Sons, 2011.

↩

SPECIFICATIONS

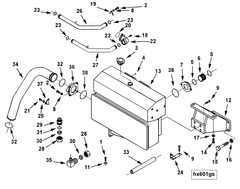

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.