This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

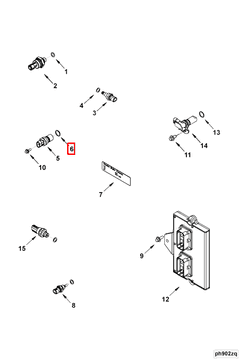

The 3408438 O-Ring Seal, manufactured by Cummins, is a component used in commercial trucks. It is designed to maintain system integrity by preventing leaks and ensuring the proper functioning of various systems. Seals play a significant role in the overall performance and reliability of truck systems, making this Cummins part an important part of truck maintenance and operation 1.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket with a circular cross-section, designed to create a seal between two or more parts. It is typically made from elastomers, which are materials that can return to their original shape after deformation. The principle behind its function is to fill the gap between mating surfaces, thereby preventing the passage of fluids or gases. O-Ring Seals are used in both dynamic and static applications, providing reliable sealing solutions in various environments 2.

Purpose of the 3408438 O-Ring Seal in Truck Operations

This part is utilized in several areas of truck operations, including engine components, fuel systems, and hydraulic systems. It plays a role in maintaining the integrity of these systems by ensuring that fluids and gases remain contained within their designated pathways. This helps in preserving the efficiency and performance of the truck’s systems 3.

Key Features of the 3408438 O-Ring Seal

This Cummins part is designed with specific features that enhance its performance and durability. It is made from materials that offer resistance to a range of chemicals and temperatures, ensuring it can withstand the harsh conditions often encountered in truck operations. Additionally, its design allows for compatibility with various other materials, making it a versatile component in truck systems 4.

Benefits of Using the 3408438 O-Ring Seal

The use of this part provides several advantages. It contributes to improved system reliability by ensuring that seals remain intact under various conditions. This can lead to reduced maintenance needs, as the seal is less likely to fail or require replacement. Furthermore, its performance in harsh operating conditions helps maintain the overall efficiency of the truck’s systems 5.

Installation Considerations

Proper installation of the 3408438 O-Ring Seal is important to ensure a secure and effective seal. Best practices include ensuring the mating surfaces are clean and free from debris, using the correct tools for installation, and avoiding common mistakes such as over-tightening or damaging the seal during installation 6.

Troubleshooting Common Issues

Typical problems associated with O-Ring Seals include leaks or failure. These issues can often be diagnosed by inspecting the seal for signs of wear, damage, or improper installation. Resolving these issues may involve replacing the seal, ensuring proper installation, or addressing underlying problems such as contamination or excessive pressure 7.

Maintenance and Replacement

Regular inspection and maintenance of the 3408438 O-Ring Seal are recommended to ensure its continued performance. Signs that indicate the need for replacement include visible damage, leaks, or a decrease in system performance. The correct procedures for replacement should be followed to ensure the new seal is installed effectively 8.

Cummins: A Brief Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its commitment to quality and innovation. The company offers a wide range of products, including engines, filtration systems, and aftermarket parts. Cummins’ reputation is built on its dedication to providing reliable and high-performing components for the trucking industry 9.

O-Ring Seal 3408438 Compatibility with Cummins Engines

The O-Ring Seal part number 3408438, manufactured by Cummins, is designed to fit a variety of Cummins engines. This seal is crucial for maintaining the integrity of the engine’s sealing system, ensuring that there are no leaks and that the engine operates efficiently. Below is a detailed description of the compatibility of this O-Ring Seal with various Cummins engines:

ISB Series Engines

- ISB CM550

- ISB CM850

- ISB5.9 CM2880 B110

- ISB5.9 CM2880 B140

- ISB5.9G CM2180

The O-Ring Seal 3408438 is compatible with the ISB series engines, which are known for their robust performance and reliability. These engines are widely used in various applications, including heavy-duty trucks and industrial machinery.

ISC Series Engines

- ISC CM554

- ISC CM850

The O-Ring Seal 3408438 fits seamlessly with the ISC series engines, which are designed for high-performance applications. These engines are often used in construction equipment and other heavy machinery.

ISF Series Engines

- ISF2.8 CM2220 F129

This seal is also compatible with the ISF series engines, providing a reliable seal for the engine’s critical components.

ISL Series Engines

- ISL CM554

- ISL9 CM2150 SN

The O-Ring Seal 3408438 is designed to fit the ISL series engines, which are known for their durability and efficiency. These engines are commonly used in on-highway and vocational applications.

QSB Series Engines

- QSB3.9 30 CM550

- QSB5.9 30 CM550

- QSB5.9 CM2880 B115

- QSB5.9 CM850

This seal is compatible with the QSB series engines, which are designed for a wide range of applications, including agricultural, construction, and industrial use.

QSC Series Engines

- QSC8.3 CM554

- QSC8.3 CM850 (CM2850)

- QSC9 CM2250/QSL9 CM2250

The O-Ring Seal 3408438 fits the QSC series engines, which are known for their versatility and performance. These engines are used in various applications, including power generation and industrial equipment.

QSK Series Engines

- QSK19 CM2350 K105

- QSK19 CM2350 K114

- QSK19 CM500

- QSK19G

- QSK78 CM500

This seal is compatible with the QSK series engines, which are designed for high-performance applications. These engines are often used in heavy-duty trucks and industrial machinery.

B Series Engines

- B5.9 GAS PLUS CM556

The O-Ring Seal 3408438 is also compatible with the B series engines, providing a reliable seal for these engines’ critical components.

L Series Engines

- L8.9G CMOH2.0 L125B

This seal fits the L series engines, ensuring that the engine operates efficiently and without leaks.

By ensuring that the O-Ring Seal 3408438 is correctly installed, engine operators can maintain the performance and longevity of their Cummins engines.

Role of Part 3408438 O-Ring Seal in Engine Systems

The O-Ring Seal, part number 3408438, is an essential component in ensuring the integrity and efficiency of various engine systems. Its application spans across multiple components, providing necessary sealing to prevent leaks and maintain system performance.

Air Intake Manifold Kit

In the Air Intake Manifold Kit, the O-Ring Seal is used to create a tight seal between the manifold and the engine block. This ensures that the air-fuel mixture is delivered efficiently to the cylinders without any leaks, which could otherwise lead to performance issues.

Position Speed Sensor and Position Sensor

For the Position Speed Sensor and Position Sensor, the O-Ring Seal is employed to seal the sensor housing to the engine block or transmission housing. This prevents contaminants from entering the sensor cavity and ensures accurate readings, which are vital for engine management.

Cylinder and Cylinder Block

Within the Cylinder and Cylinder Block, the O-Ring Seal is utilized to seal various passages and ports. This includes sealing oil galleries and coolant passages, ensuring that fluids remain within their designated paths and do not mix or leak out.

Engine Control Module (ECM) and Engine Control Module Housing

In the Engine Control Module (ECM) and its housing, the O-Ring Seal is critical for protecting the sensitive electronic components from moisture and contaminants. This seal ensures the longevity and reliability of the ECM.

Gear Housing and Gear Housing Plug

For the Gear Housing and Gear Housing Plug, the O-Ring Seal is used to maintain the integrity of the gear housing, preventing lubricant leakage and ensuring that the gears operate smoothly without contamination.

Flywheel and Front Gear Housing

In the Flywheel and Front Gear Housing, the O-Ring Seal helps in sealing the interface between the flywheel and the gear housing. This prevents lubricant loss and keeps the mating surfaces clean, which is essential for the proper functioning of the transmission system.

Service Coupling 2008 Assembly and Service Coupling 2009 Assembly

In both the Service Coupling 2008 Assembly and Service Coupling 2009 Assembly, the O-Ring Seal is used to ensure a leak-proof connection between the coupling components. This is important for maintaining the pressure and integrity of the fluid lines within the engine system.

Threaded Plug

Lastly, the O-Ring Seal is often used with Threaded Plugs to seal off unused ports or passages within the engine block or other housings. This prevents fluid leakage and ensures that the engine operates within specified parameters.

Overall, the O-Ring Seal, part number 3408438, plays a significant role in maintaining the efficiency and reliability of various engine components by providing essential sealing in critical applications.

Conclusion

The 3408438 O-Ring Seal is a critical component in the maintenance and operation of commercial trucks, particularly those equipped with Cummins engines. Its role in preventing leaks and ensuring the proper functioning of various systems underscores its importance in truck maintenance. Proper installation, regular maintenance, and timely replacement of this part are essential to ensure the continued performance and reliability of truck systems.

-

Heywood, J. (2019). Internal Combustion Engine Fundamentals. McGraw-Hill Education.

↩ -

Bennett, S. (2012). Modern Diesel Technology: Light Duty Diesels. Cengage Learning.

↩ -

Pulkrabek, W. W. (2014). Engineering Fundamentals of the Internal Combustion Engine. Pearson Education.

↩ -

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for KTAA19 K131 G Engines. Bulletin Number 5504187.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for KTAA19 K131 G Engines. Bulletin Number 5504187.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for KTAA19 K131 G Engines. Bulletin Number 5504187.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for KTAA19 K131 G Engines. Bulletin Number 5504187.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for KTAA19 K131 G Engines. Bulletin Number 5504187.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.