3417238

O Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

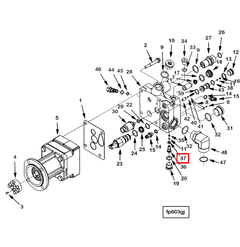

The Cummins 3417238 O-Ring Seal is a component designed to ensure the integrity of seals within commercial truck engines. Its role is significant in maintaining the efficiency and reliability of truck operations by preventing leaks and ensuring proper system function 1.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket with a circular cross-section, used to create a seal between two or more parts. It operates by being compressed within a groove, forming a barrier that prevents the passage of fluids or gases. O-Ring Seals are widely utilized in mechanical systems for their simplicity, effectiveness, and versatility in creating reliable seals in various applications 2.

Purpose of the 3417238 O-Ring Seal

This Cummins part is specifically designed to play a role in the sealing mechanisms of Cummins engines. It is associated with various systems or components within the engine, ensuring that fluids and gases remain contained within their designated pathways. This helps maintain the engine’s performance and longevity by preventing leaks that could lead to system inefficiencies or damage 3.

Key Features

The 3417238 O-Ring Seal is characterized by its material composition, typically made from durable elastomers that offer resistance to a range of environmental factors. Its dimensions are precisely engineered to fit specific grooves within the engine components, ensuring a snug fit and effective seal. Unique characteristics such as its flexibility and resilience enhance its performance under varying operating conditions 4.

Benefits

Utilizing the 3417238 O-Ring Seal provides several advantages, including improved sealing efficiency, which contributes to the overall performance of the engine. Its durability ensures long-term reliability, while its resistance to various environmental factors, such as temperature extremes and chemical exposure, enhances its suitability for use in demanding commercial truck applications 1.

Installation Process

Proper installation of the 3417238 O-Ring Seal involves careful handling to avoid damage. It should be placed in the designated groove without twisting or kinking. Tools such as lubricants may be recommended to facilitate the fitting process, ensuring the O-Ring Seal is correctly positioned and compressed to form an effective seal 2.

Troubleshooting Common Issues

Common problems associated with O-Ring Seals include leaks or wear, which can arise from improper installation, degradation over time, or exposure to incompatible fluids. Troubleshooting steps may involve inspecting the seal for signs of damage, ensuring it is correctly installed, and replacing it if necessary to restore system integrity 3.

Maintenance Tips

Regular maintenance of the 3417238 O-Ring Seal includes periodic inspections for signs of wear or damage. Cleaning procedures should be followed to remove any contaminants that could affect its performance. Replacement should be considered if the seal shows signs of degradation or if leaks are detected, to maintain the efficiency and reliability of the engine system 4.

Compatibility with Cummins Engines

The O-Ring Seal part number 3417238, manufactured by Cummins, is designed to fit a variety of Cummins engines. This seal is crucial for maintaining the integrity of fluid systems and preventing leaks in high-pressure environments. Below is a detailed description of its compatibility with the listed engines:

ISX Series Engines

- ISX12 CM2350 X102

- ISX12/ISX11.9 CM2250

- ISX15 CM2250

- ISX15 CM2250 SN

- ISX15 CM2350 X101

ISZ Series Engines

- ISZ13 CM2150 Z105

QSK Series Engines

- QSK19 CM2350 K144G

- QSK19 CM500

- QSK45 CM500

- QSK50 CM2350 K108

- QSK60 CM500

- QSK60G

- QSK78 CM500

- QSK95 CM2350 K111

- QSK95 CM2350 K113

QSX Series Engines

- QSX11.9 CM2250 ECF

- QSX15 CM2250

- QSX15 CM2250 ECF

- QSX15 CM2350 X105

QSZ Series Engines

- QSZ13 CM2150 Z101

- QSZ13 CM2150 Z102

VTA Series Engines

- VTA903 CM2250 V105

X Series Engines

- X15 CM2350 X116B

- X15 CM2350 X123B

- X15 CM2450 X134B

Role of Part 3417238 O-Ring Seal in Engine Systems

This part is an essential component in ensuring the integrity and efficiency of various engine systems. It is strategically placed in areas where sealing is required to prevent leaks and maintain pressure.

In the fuel injection pump and gear fuel pump, the O-Ring Seal is used to create a tight seal around moving parts, ensuring that fuel is delivered under precise pressure without any leakage. This is particularly important in high-pressure systems like the Fuel Systems HD XPI where even minor leaks can significantly affect performance.

Within the fuel system, the O-Ring Seal is employed in the pressure regulator valve and pressure relief valve to maintain consistent fuel pressure. It also plays a role in the pressure sensor and pressure temperature sensor by ensuring accurate readings by preventing any fuel from bypassing these critical components.

In the valve cover and around the valve components, the O-Ring Seal helps in maintaining the integrity of the engine’s lubrication system. It ensures that oil does not leak out, which is vital for the proper functioning and longevity of the engine.

For the fuel supply plumbing and connections, such as those found in the XPI JV System Cummins HD, XPI JV System Scania HD, and XPI JV System Texas, the O-Ring Seal is used to secure fittings and prevent fuel from escaping. This is essential in high-demand engines where fuel efficiency and reliability are paramount.

Additionally, in the engine control module and related components, the O-Ring Seal is used to protect electronic sensors and connectors from fuel or oil contamination, ensuring the accurate operation of the engine’s control systems.

The filter plug and threaded plug also benefit from the O-Ring Seal, as it ensures that these components remain securely in place and do not allow any fluids to escape, which could lead to system failures or inefficiencies.

Conclusion

Overall, the 3417238 O-Ring Seal is a fundamental component in maintaining the operational integrity of various engine systems, ensuring that they function efficiently and reliably. Its role in preventing leaks, maintaining pressure, and protecting critical components underscores its importance in the maintenance and performance of commercial truck engines.

-

BT Fijalkowski, Automotive Mechatronics Operational and Practical Issues Volume 1, Springer, 2011.

↩ ↩ -

Klaus Mollenhauer and Helmut Tschoeke, Handbook of Diesel Engines, Springer, 2010.

↩ ↩ -

Haoran Hu, Rudy Smaling, and Simon Baseley, Heavy-Duty Wheeled Vehicles, SAE International, 2014.

↩ ↩ -

John Kasab and Andrea Strzelec, Automotive Emissions Regulations and Exhaust Aftertreatment Systems, SAE International, 2020.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.