This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3420659 O-Ring Seal is a component designed to ensure the integrity of fluid systems in commercial trucks. Its purpose is to create a reliable seal in various applications, contributing to the overall efficiency and reliability of truck operations. Understanding the role and significance of this O-Ring Seal is vital for maintaining the performance and longevity of commercial vehicles.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket with a circular cross-section, designed to create a seal between two or more parts. It operates by being compressed within a groove, forming a barrier that prevents the leakage of fluids or gases. O-Ring Seals are widely used in mechanical systems due to their simplicity, effectiveness, and versatility in various applications 1.

Purpose of the 3420659 O-Ring Seal in Truck Operation

This Cummins part plays a specific role in the operation of commercial trucks by ensuring the sealing of fluid systems. It is applied in areas where fluid transfer occurs, such as in hydraulic systems, fuel lines, and engine compartments. By maintaining a secure seal, it supports the efficient operation of these systems, preventing leaks that could lead to performance issues or safety hazards.

Key Features of the 3420659 O-Ring Seal

The design and material characteristics of this part contribute to its effectiveness. It is made from materials that offer durability and resistance to a range of chemicals and temperatures. This ensures that the seal remains intact under various operating conditions, providing compatibility with other components and systems within the truck.

Benefits of Using the 3420659 O-Ring Seal

Utilizing this Cummins part offers several advantages. It enhances system reliability by ensuring that fluid systems operate without leaks. This reduces the need for frequent maintenance and contributes to the overall performance of the truck. The seal’s durability and resistance properties also mean that it can withstand the demanding conditions of commercial truck operation 2.

Installation and Maintenance Guidelines

Proper installation of this part involves preparing the sealing surface to ensure it is clean and free from debris. The seal should be placed correctly within the designated groove to ensure optimal performance. Regular maintenance checks can help identify any signs of wear or damage, allowing for timely replacement and ensuring the longevity and optimal performance of the seal.

Troubleshooting Common Issues

Common problems associated with O-Ring Seals include leaks or failure due to wear, improper installation, or exposure to incompatible fluids or temperatures. Troubleshooting these issues involves inspecting the seal for signs of damage, ensuring it is correctly installed, and verifying that it is compatible with the fluids and operating conditions it encounters 3.

Compatibility with Cummins Engines

The O-Ring Seal part number 3420659, manufactured by Cummins, is designed to fit seamlessly within several of their engine models. This part is integral to maintaining the integrity of the engine’s sealing system, ensuring that there are no leaks or unwanted fluid movement.

QSW/QSV82 Engines

In the QSW/QSV82 engines, 3420659 is utilized in critical areas where sealing is paramount. This includes sealing between rotating components and stationary parts, preventing the escape of fluids such as oil and coolant. Its placement in these engines ensures that the engine operates efficiently and reliably by maintaining the necessary pressure and preventing contamination.

QSW27 and QSW36 Engines

Similarly, 3420659 is also compatible with the QSW27 and QSW36 engines. These engines, like the QSW/QSV82, benefit from the precise sealing provided by this O-Ring. The part’s design ensures that it can withstand the operational stresses and conditions within these engines, providing a long-lasting and dependable seal.

QSW73 Engines

The QSW73 engines also incorporate 3420659 in their design. This part plays a role in maintaining the engine’s sealing integrity, ensuring that all moving parts are properly sealed from the surrounding environment. Its application in these engines helps in maintaining optimal engine performance and longevity.

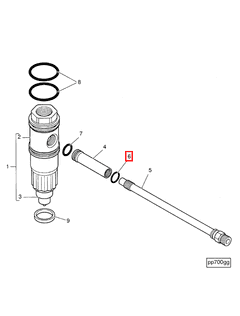

Role of Part 3420659 O-Ring Seal in Engine Systems

The O-Ring Seal, identified by part number 3420659, is integral to the functionality and efficiency of various engine components. In the context of an Assembly Injector, this seal ensures a tight and secure connection between the injector and the fuel rail, preventing any fuel leakage that could compromise engine performance.

Within the Injector itself, the O-Ring Seal plays a role in maintaining the integrity of the fuel delivery system. It ensures that fuel is delivered under precise pressure conditions, which is essential for optimal combustion and overall engine efficiency.

For the Injector Assembly, the O-Ring Seal is vital in creating a leak-proof environment. This is particularly important in high-pressure fuel systems where even minor leaks can lead to significant performance issues, including reduced fuel efficiency and potential engine damage.

In terms of Parts and Performance, the O-Ring Seal contributes to the longevity and reliability of the engine components it is associated with. By preventing leaks and maintaining pressure integrity, it helps in sustaining the performance levels of the engine over time. This is especially relevant in high-performance engines where precision and reliability are paramount 4.

Conclusion

The Cummins 3420659 O-Ring Seal is a critical component in ensuring the efficiency and reliability of fluid systems in commercial trucks. Its proper installation and maintenance are essential for preventing leaks and ensuring the longevity of engine components. Understanding its role and significance can contribute to the overall performance and safety of commercial vehicles.

-

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ -

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩ -

Fehan, D. R. (2013). Design of Racing and High-Performance Engines 2004-2013. SAE International.

↩ -

ElGindy, M., & ElSayegh, Z. (2023). Road and Off-Road Vehicle Dynamics. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.