3420801

O-Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3420801 O-Ring Seal is a specialized component designed for use in commercial trucks. Its primary purpose is to provide a reliable seal in various applications within the truck’s systems, ensuring the integrity of fluid and gas pathways. This seal is integral to maintaining the performance and efficiency of the truck’s engine and other mechanical systems.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket consisting of a toroidal (doughnut-shaped) piece of elastomer. It functions by creating a seal between two or more parts, preventing the leakage of fluids or gases. O-Ring Seals are widely used in mechanical systems due to their simplicity, effectiveness, and versatility. They are commonly employed in applications where dynamic sealing is required, such as in pistons, valves, and fluid transfer systems 1.

Purpose of the 3420801 O-Ring Seal in Truck Operation

The Cummins 3420801 O-Ring Seal plays a specific role in the operation of commercial trucks by ensuring the sealing of critical components within the engine and other systems. It is typically located in areas where fluid or gas transfer occurs, such as fuel injectors, coolant systems, and hydraulic components. The seal helps maintain pressure, prevent leaks, and ensure the efficient operation of these systems.

Key Features

The Cummins 3420801 O-Ring Seal is characterized by several key features that make it suitable for heavy-duty applications. It is composed of high-quality elastomer materials that offer excellent resistance to wear, tear, and environmental factors. The seal is designed to withstand high pressures and temperatures, ensuring durability and reliability in demanding conditions. Additionally, its precise manufacturing tolerances ensure a perfect fit within the truck’s systems.

Benefits

Using the Cummins 3420801 O-Ring Seal provides several benefits. It offers improved sealing performance, which helps maintain system efficiency and prevent leaks. The seal’s durability ensures a longer service life, reducing the need for frequent replacements. Furthermore, its resistance to various operating conditions, including extreme temperatures and pressures, enhances the overall reliability of the truck’s systems 2.

Installation Considerations

Proper installation of the Cummins 3420801 O-Ring Seal is crucial for ensuring its function and longevity. Guidelines for installation include ensuring the sealing surfaces are clean and free of debris, using the correct lubrication to facilitate seating, and avoiding over-tightening, which can damage the seal. Following these best practices will help maintain the integrity of the seal and the systems it protects.

Troubleshooting Common Issues

Common problems associated with O-Ring Seals include leaks, wear, and failure due to environmental factors. Troubleshooting steps may involve inspecting the seal for signs of damage, checking the sealing surfaces for cleanliness and proper fit, and replacing the seal if necessary. Regular maintenance and timely replacement can help address these issues effectively.

Maintenance Tips

Regular maintenance of the Cummins 3420801 O-Ring Seal is important for prolonging its service life and ensuring continued reliable performance. Maintenance tips include periodic inspection for signs of wear or damage, cleaning the sealing surfaces during routine maintenance, and replacing the seal according to the manufacturer’s recommendations or when signs of failure are detected.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing high-quality, reliable components. The company’s extensive product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial transportation.

Cummins O-Ring Seal 3420801 Compatibility with Engine Models

The Cummins O-Ring Seal part number 3420801 is designed to fit seamlessly with a variety of engine models. This O-Ring Seal is engineered to provide a reliable seal in high-pressure environments, ensuring that the engine operates efficiently and safely. Below is a detailed breakdown of the engine models that are compatible with this O-Ring Seal.

Compatible Engine Models

- QSV81G

- QSV91-G4 CM558/CM700 V102

- QSV91G

- QSW/QSV82

- QSW27

- QSW36

- QSW73

Grouping of Compatible Engines

The O-Ring Seal 3420801 is versatile and fits a range of Cummins engines. Here’s a grouping of the engines based on their compatibility:

-

QSV Series Engines

- QSV81G

- QSV91-G4 CM558/CM700 V102

- QSV91G

- QSW/QSV82

-

QSW Series Engines

- QSW27

- QSW36

- QSW73

This grouping helps in understanding the broad applicability of the O-Ring Seal across different engine series within the Cummins lineup. Each engine model listed above benefits from the precise fit and reliable sealing properties of the 3420801 O-Ring Seal, ensuring optimal performance and longevity.

Role of Part 3420801 O-Ring Seal in Engine Systems

The O-Ring Seal, identified as part 3420801, is integral to maintaining the integrity and efficiency of various engine systems. Its application spans across multiple components, ensuring that fluids and gases are contained within their designated pathways, thereby preventing leaks and maintaining system pressure.

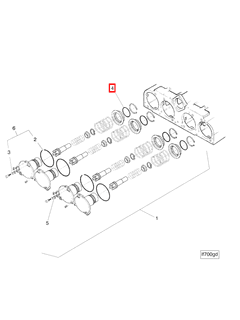

Accessory Drive Assembly Housing

In the accessory drive assembly housing, the O-Ring Seal is positioned to secure the interface between rotating and stationary components. This ensures that lubricants and coolants do not escape, which is essential for the smooth operation and longevity of the accessory drive system.

Coolant Heater Starting Aid

For the coolant heater starting aid, the O-Ring Seal plays a significant role in sealing the connections between the heater element and the coolant passages. This prevents coolant loss and ensures that the heater can effectively warm the engine, facilitating easier starts in cold conditions.

Thermostat Housing

Within the thermostat housing, the O-Ring Seal is critical for maintaining a tight seal around the thermostat. This ensures that coolant flow is regulated accurately, which is vital for maintaining optimal engine temperature and efficiency.

Lubricating Oil Filter Assembly Housing

In the lubricating oil filter assembly housing, the O-Ring Seal ensures that oil does not leak from the filter housing. This is essential for maintaining proper oil pressure and ensuring that the filter can effectively remove contaminants from the oil, prolonging engine life.

Sea Water and Power Take-Off Assembly Housing

For the sea water and power take-off assembly housing, the O-Ring Seal is used to prevent sea water from entering the engine compartments. This is particularly important in marine applications where corrosion and water ingress can lead to significant engine damage.

Full Flow Oil Filter

In the full flow oil filter, the O-Ring Seal is employed to create a secure connection between the filter and the housing. This ensures that oil flows through the filter without any bypass, which is essential for effective filtration and engine protection.

Preheater Mounting Housing

The preheater mounting housing utilizes the O-Ring Seal to ensure that any preheating fluids are contained within the system. This is important for maintaining the efficiency of the preheating process and preventing fluid loss.

Flywheel Housing Assembly

In the flywheel housing assembly, the O-Ring Seal is used to prevent lubricants from escaping, which is vital for maintaining the lubrication of moving parts and ensuring the smooth operation of the flywheel.

Front Gear Train Accessory Drive

For the front gear train accessory drive, the O-Ring Seal ensures that the interface between the drive components and the housing remains sealed. This is important for preventing lubricant loss and maintaining the efficiency of the accessory drive system.

Heat Assembly Exchanger

In the heat assembly exchanger, the O-Ring Seal is critical for maintaining the seal between the heat exchange components. This ensures that the transfer of heat between fluids is efficient and that there is no cross-contamination or loss of fluid.

By understanding the role of the O-Ring Seal in these various engine components, engineers and mechanics can better appreciate its importance in maintaining the overall performance and reliability of the engine system.

Conclusion

The Cummins 3420801 O-Ring Seal is a critical component in the maintenance and efficiency of commercial truck engines. Its design and features ensure reliable sealing in various applications, contributing to the overall performance and longevity of the engine systems. Proper installation, regular maintenance, and timely replacement are essential practices to ensure the continued effectiveness of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.