This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3421125 O-Ring Seal is a critical component designed to maintain the integrity of fluid systems in commercial trucks. Its role in providing a reliable seal in various applications contributes to the efficient operation of the vehicle. Understanding its purpose and significance is essential for maintaining the performance and longevity of truck systems.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket with a circular cross-section, designed to create a seal between two or more parts. It functions by being compressed within a groove, forming a barrier that prevents the leakage of fluids or gases. O-Ring Seals are widely used in mechanical systems due to their simplicity, effectiveness, and versatility in sealing applications 1.

Purpose of the Cummins 3421125 O-Ring Seal

The Cummins 3421125 O-Ring Seal is specifically engineered to play a role in the sealing mechanisms of truck systems. It is positioned in areas where fluid dynamics are critical, such as in fuel systems, hydraulic systems, and engine components. Its function is to maintain the integrity of these systems by preventing leaks, which could lead to inefficiencies or failures 2.

Key Features

The Cummins 3421125 O-Ring Seal is characterized by its material composition, typically made from durable elastomers that can withstand a range of temperatures and pressures. Its design is tailored to ensure a snug fit within the designated grooves, enhancing its sealing capabilities. The seal’s resilience and flexibility contribute to its performance, allowing it to adapt to the dynamic conditions within a truck’s operating environment 3.

Benefits of Using the Cummins 3421125 O-Ring Seal

Utilizing the Cummins 3421125 O-Ring Seal offers several advantages. It provides improved sealing efficiency, which is vital for maintaining system performance. Its durability ensures longevity, reducing the frequency of replacements. Additionally, its reliability in harsh operating conditions makes it a preferred choice for commercial truck applications 4.

Installation and Maintenance

Proper installation of the Cummins 3421125 O-Ring Seal involves careful preparation of the groove to ensure a clean and undamaged surface. The use of appropriate tools is recommended to avoid damaging the seal during installation. Regular maintenance, including inspection for wear and tear, is important to ensure the seal continues to perform effectively over time 5.

Troubleshooting Common Issues

Common issues with O-Ring Seals, such as leaks or failures, can often be traced back to improper installation, environmental factors, or wear. Troubleshooting these problems involves a systematic approach to identify the root cause, whether it be a misfit, degradation of the seal material, or external damage. Addressing these issues promptly can prevent more significant problems down the line 6.

Manufacturer: Cummins

Cummins is a well-established manufacturer with a strong reputation in the automotive and heavy-duty truck industries. The company is known for its commitment to quality and innovation, producing a wide range of components that are integral to the performance and reliability of commercial vehicles. Cummins’ dedication to excellence is reflected in the design and manufacturing of the 3421125 O-Ring Seal.

Cummins O-Ring Seal Part 3421125 Compatibility with Engine Models

The Cummins O-Ring Seal part number 3421125 is designed to fit seamlessly with a range of engine models, ensuring optimal sealing performance and reliability. This part is engineered to meet the stringent requirements of various engine applications, providing a critical seal that prevents leaks and maintains system integrity.

Compatibility with QSV81G and QSV91G Engines

The O-Ring Seal part 3421125 is compatible with the QSV81G and QSV91G engines. These engines are known for their robust design and high performance, often used in demanding industrial and commercial applications. The seal ensures that the engine’s internal components remain protected from contaminants and wear, contributing to the engine’s longevity and efficiency.

Compatibility with QSW/QSV82, QSW27, and QSW36 Engines

The O-Ring Seal part 3421125 also fits the QSW/QSV82, QSW27, and QSW36 engines. These engines are part of a series that offers a balance of power and reliability, suitable for various applications including heavy-duty trucks and industrial machinery. The seal’s precision fit and durability make it an essential component for maintaining the engines’ operational efficiency and preventing fluid leaks.

Compatibility with QSW73 Engine

Lastly, the O-Ring Seal part 3421125 is designed to work with the QSW73 engine. This engine is recognized for its versatility and performance, often used in applications where reliability and efficiency are paramount. The seal’s compatibility with the QSW73 engine ensures that it can withstand the operational stresses and provide a dependable seal, enhancing the engine’s overall performance.

Role of Part 3421125 O-Ring Seal in Engine Systems

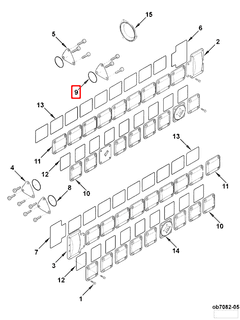

The part 3421125 O-Ring Seal is integral to the effective functioning of various engine components by ensuring fluid and pressure integrity. In the arrangement of engine parts, this O-Ring Seal is positioned to create a tight seal between mating surfaces, preventing leaks and maintaining system efficiency.

Within the oil fill system, the O-Ring Seal is utilized to secure the connection points, ensuring that oil does not escape and contaminate other engine components or the environment. This is particularly important in maintaining the lubrication necessary for the smooth operation of moving parts.

The control assembly cover relies on the O-Ring Seal to maintain a sealed environment, protecting sensitive electronic and mechanical components from debris and moisture. Similarly, in the electric assembly governor and electric governor, the seal ensures that electrical connections remain intact and free from interference by external elements.

In the electronic control cooler, the O-Ring Seal plays a role in maintaining the coolant’s path without leakage, which is essential for regulating the temperature of electronic components and ensuring their reliable performance.

The engine assembly cover and engines assembly cover both depend on the O-Ring Seal to create a barrier against oil, fuel, and other fluids, preserving the integrity of the engine’s internal environment.

For the governor, electronic and governor, hydraulic, the O-Ring Seal is critical in maintaining the precise control of fuel delivery and engine speed by preventing any unauthorized fluid movement that could disrupt performance.

In the governor assembly bracket and governor assembly housing, the seal ensures that all connections are secure, allowing for accurate and consistent operation of the governor system.

The hydraulic assembly governor and hydraulic governor systems benefit from the O-Ring Seal by ensuring that hydraulic fluid is contained within its intended pathways, which is vital for the actuation of various engine controls.

Lastly, in the seal kit and sensor assembly housing, the O-Ring Seal is often a component itself, designed to replace worn seals and maintain the sensor’s accuracy by keeping out contaminants and ensuring a stable operating environment.

Conclusion

The Cummins 3421125 O-Ring Seal is a vital component in the maintenance and efficiency of commercial truck systems. Its design, compatibility with various engine models, and role in preventing leaks and maintaining system integrity underscore its importance in the automotive industry. Proper installation, maintenance, and understanding of common issues are key to maximizing the benefits of this Cummins part.

-

Martyr, A.J. Engine Testing: Theory and Practice: Third Edition. SAE International, 2007.

↩ -

Fijalkowski, BT. Automotive Mechatronics Operational and Practical Issues Volume 1. Springer, 2011.

↩ -

Aird, Forbes. Bosch Fuel Injection Systems. HP Books, 2001.

↩ -

Peters, George; Peters, Barbara J. Automobile Vehicle Safety. CRC Press, 2002.

↩ -

Cummins. Owners Manual. Bulletin Number 4332714, QSX15 CM2350 X106.

↩ -

Cummins. Owners Manual. Bulletin Number 4332714, QSX15 CM2350 X106.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.