This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3421308 O-Ring Seal is a component designed to ensure the integrity of fluid systems within commercial trucks. Its role is to prevent leaks and maintain system pressure, contributing to the overall efficiency and reliability of the vehicle. Understanding its function and significance is key to maintaining the operational standards of commercial trucks.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a toroidal (ring-shaped) elastomer with a circular cross-section, used to create a seal between two or more parts. It functions by being compressed within a groove, creating a barrier that prevents the passage of fluids or gases. O-Ring Seals are widely utilized in mechanical systems for their simplicity, effectiveness, and versatility in sealing applications 1.

Purpose of the 3421308 O-Ring Seal

The 3421308 O-Ring Seal is specifically designed to fit within the fluid systems of trucks manufactured by Cummins. It plays a role in maintaining the seal at specific points within the system, ensuring that fluids remain contained and pressures are maintained. Its location and function are critical to the operation of the truck’s fluid systems, contributing to the vehicle’s performance and longevity 2.

Key Features

The 3421308 O-Ring Seal is constructed from materials that offer durability and resistance to a range of operating conditions. Its design is tailored to withstand the pressures and temperatures encountered in heavy-duty applications, making it a reliable component for commercial trucks. The material composition and design characteristics of this O-Ring Seal are selected to ensure it can perform effectively in demanding environments 3.

Benefits

Utilizing the 3421308 O-Ring Seal provides several advantages, including enhanced sealing efficiency, extended longevity, and resilience against various operating conditions. These benefits contribute to the overall reliability of the truck’s fluid systems, reducing the likelihood of leaks and maintaining system integrity over time.

Installation Process

Proper installation of the 3421308 O-Ring Seal is vital for its performance and longevity. The process involves ensuring the groove is clean and free of debris, selecting the correct size O-Ring, and installing it without twisting or damaging the seal. Careful attention to these steps ensures the O-Ring Seal functions as intended, providing a reliable seal within the system.

Troubleshooting Common Issues

Common problems with O-Ring Seals include leaks, which can arise from improper installation, wear and tear, or exposure to incompatible fluids. Troubleshooting these issues involves inspecting the seal for damage, ensuring it is correctly installed, and verifying compatibility with the system’s fluids. Addressing these problems promptly helps maintain the integrity of the truck’s fluid systems.

Maintenance Tips

Regular maintenance of the 3421308 O-Ring Seal is recommended to prolong its lifespan and ensure continued reliable performance. This includes periodic inspection for signs of wear or damage, cleaning the seal and its groove, and replacing the seal as necessary. Adhering to these maintenance practices contributes to the overall efficiency and reliability of the truck’s fluid systems.

Compatibility with Engine Models

This Cummins part is designed to fit seamlessly within a variety of engine models, ensuring optimal sealing performance and reliability. It is engineered to meet the stringent requirements of modern diesel engines, providing a critical barrier against leaks and contamination.

Engine Models QSV81G and QSV91G

The O-Ring Seal 3421308 is compatible with the QSV81G and QSV91G engines. These engines are known for their robust design and high performance, often used in heavy-duty applications. The O-Ring Seal ensures that the engine maintains its operational integrity by preventing fluid leaks and maintaining pressure within the system.

Engine Models QSW/QSV82 and QSW27

The O-Ring Seal 3421308 also fits the QSW/QSV82 and QSW27 engines. These engines are part of a series that balances power and efficiency, making them suitable for a range of applications from industrial to agricultural use. The O-Ring Seal’s precision fit and durability are crucial in these engines, where consistent performance is essential.

Engine Models QSW36 and QSW73

Lastly, the O-Ring Seal 3421308 is designed to work with the QSW36 and QSW73 engines. These engines are engineered for versatility and reliability, often used in demanding environments. The O-Ring Seal’s role in these engines is to provide a tight seal, ensuring that the engine operates smoothly and efficiently without any leaks.

Role of Part 3421308 O-Ring Seal in Engine Systems

The Part 3421308 O-Ring Seal is integral to maintaining the efficiency and reliability of various engine systems. Its primary function is to ensure a tight seal in areas where fluid or gas passage is required, preventing leaks and maintaining system integrity.

Breather Systems

In breather systems, the O-Ring Seal is used to secure connections and joints. This ensures that the breather functions correctly by allowing pressure equalization within the crankcase without allowing contaminants to enter.

Crankcase and Crankcase Assembly Breather

Within the crankcase and its assembly breather, the O-Ring Seal plays a significant role in sealing the breather mounting points. This prevents oil vapors and crankcase gases from escaping, which could lead to contamination or loss of lubrication.

Air Shutdown Device

For the air shutdown device, the O-Ring Seal is employed to create a reliable seal at connection points. This ensures that the device can effectively control airflow, maintaining engine performance during shutdown procedures.

Exhaust Assembly and Manifold

In the exhaust assembly and manifold, the O-Ring Seal is critical for sealing connections between the exhaust manifold and other components. This prevents exhaust gases from leaking, ensuring efficient emission control and maintaining the integrity of the exhaust system.

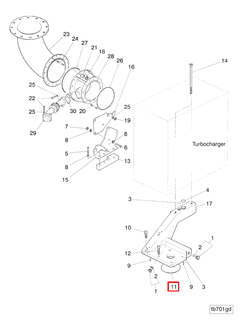

Turbocharger Assembly Support

The O-Ring Seal is also utilized in the turbocharger assembly support to seal various connections. This helps in maintaining the turbocharger’s efficiency by ensuring that no air or gas leaks occur, which could affect performance and lead to potential damage.

Separator Air-Oil Module

In the separator air-oil module, the O-Ring Seal ensures that the separation process between air and oil is effective. This maintains the purity of the air and oil, contributing to the overall efficiency and longevity of the engine system.

Seal Kit

When included in a seal kit, the O-Ring Seal is used to replace worn or damaged seals in various engine components. This restoration of seals helps in maintaining the performance and reliability of the engine by preventing leaks and ensuring proper function of all sealed components.

Conclusion

The Cummins 3421308 O-Ring Seal plays a vital role in the maintenance and operation of commercial truck fluid systems. Its design, compatibility with various engine models, and the benefits it offers in terms of sealing efficiency and durability make it a critical component for ensuring the reliability and performance of commercial trucks. Proper installation, maintenance, and troubleshooting are essential practices to maximize the effectiveness of this part in engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.