This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3421317 O-Ring Seal is a specialized component designed for use in commercial trucks. Its primary function is to provide a reliable seal in various engine and system applications, ensuring the integrity of fluid systems and preventing leaks. This part is integral to maintaining the performance and efficiency of commercial trucks, particularly in demanding operational environments.

Basic Concepts of O-Ring Seals

O-Ring Seals are circular elastomeric rings used to create a seal between two or more mating surfaces. They function by deforming under compression to fill the gap between the surfaces, thereby preventing the passage of fluids or gases. O-Ring Seals are widely utilized in mechanical systems due to their simplicity, effectiveness, and versatility in various applications, including automotive, aerospace, and industrial machinery 1.

Purpose of the Cummins 3421317 O-Ring Seal

This Cummins part plays a specific role in the operation of commercial trucks by ensuring a tight seal in critical fluid systems. It is typically placed in areas where fluid transfer occurs, such as fuel lines, hydraulic systems, and engine components. The seal helps maintain system pressure, prevent fluid leaks, and ensure the efficient operation of the truck’s engine and ancillary systems.

Key Features

The Cummins 3421317 O-Ring Seal is characterized by several key features that enhance its performance. It is made from high-quality elastomeric material, which provides excellent resistance to wear, tear, and environmental factors. The seal is designed to withstand high temperatures, pressures, and a range of chemical exposures, ensuring durability and reliability in demanding applications. Additionally, its precise dimensions and tolerances ensure a proper fit and effective sealing capability 2.

Benefits of Using the Cummins 3421317 O-Ring Seal

Utilizing this part offers several advantages. The seal provides improved sealing efficiency, reducing the risk of leaks and maintaining system integrity. Its durable construction ensures longevity, even under harsh operating conditions. Furthermore, the seal’s resistance to various environmental factors enhances the overall reliability and performance of the truck’s fluid systems.

Installation and Maintenance

Proper installation of the Cummins 3421317 O-Ring Seal is crucial for ensuring optimal performance. It should be installed in a clean, dry environment to prevent contamination. The mating surfaces must be free of debris and properly aligned to allow the O-Ring to seat correctly. Routine maintenance practices, such as regular inspection for signs of wear or damage, and replacement as needed, will help maintain the seal’s effectiveness and prolong its service life 3.

Troubleshooting Common Issues

Common issues associated with O-Ring Seals include leaks and degradation over time. If a leak is detected, it is important to inspect the O-Ring for signs of damage, such as cracks or deformation. Environmental factors, such as exposure to chemicals or extreme temperatures, can also contribute to seal degradation. Addressing these issues promptly by replacing the O-Ring Seal and ensuring proper installation can help maintain system integrity and prevent further complications.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history dating back to 1919, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance engines and components. The company’s extensive product range and commitment to innovation have made it a trusted name among fleet operators and maintenance professionals.

Cummins O-Ring Seal Part 3421317 Compatibility

The Cummins O-Ring Seal part number 3421317 is designed to fit a range of engines, ensuring a reliable seal in various applications. This part is particularly compatible with the following engine models:

- QSV81G

- QSV91-G4 CM558/CM700 V102

- QSV91G

- QSW/QSV82

- QSW27

- QSW36

- QSW73

For the QSV81G and QSV91G engines, the O-Ring Seal part 3421317 provides a crucial seal in the fuel system, ensuring that there are no leaks and maintaining the integrity of the fuel lines. This is particularly important in maintaining the efficiency and reliability of the engine.

In the QSV91-G4 CM558/CM700 V102 engine, the O-Ring Seal part 3421317 is used in the turbocharger system. This ensures that the turbocharger operates efficiently by preventing any air or fluid leaks, which could otherwise lead to performance issues.

The QSW/QSV82 and QSW27 engines also benefit from the O-Ring Seal part 3421317, which is used in the cooling system. This helps to maintain the proper pressure and temperature within the cooling system, preventing any potential overheating or cooling inefficiencies.

For the QSW36 and QSW73 engines, the O-Ring Seal part 3421317 is used in the lubrication system. This ensures that the engine oil remains within the system, preventing leaks and maintaining the necessary lubrication for engine components.

Overall, the Cummins O-Ring Seal part 3421317 is a versatile and essential component for these engine models, providing critical sealing in various systems to ensure optimal engine performance and reliability.

Role of Part 3421317 O-Ring Seal in Engine Systems

The part 3421317 O-Ring Seal is integral to the effective operation of various engine components. Its primary function is to ensure a tight seal, preventing leaks and maintaining system integrity.

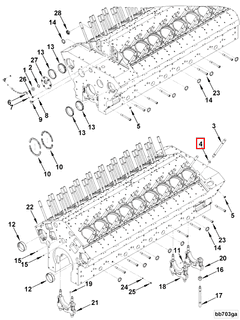

Sealing in the Engine Block and Cylinder Assembly

In the Engine Block and Cylinder Assembly Block, the O-Ring Seal is used to secure connections and interfaces. It ensures that coolant and lubricants remain within their designated pathways, preventing any cross-contamination or loss of fluids. This is particularly important in the Cylinder Block where precise fluid management is essential for optimal engine performance.

Integration with the Engine Support and Assembly

The Engine Support and Engine Assembly Support components rely on the O-Ring Seal to maintain structural integrity and fluid dynamics. By sealing joints and connections, it helps in sustaining the necessary pressure and fluid levels within the engine support systems, which are vital for the engine’s stable operation.

Application in the Gear and Camshaft Systems

In the Gear and Camshaft arrangements, the O-Ring Seal plays a role in lubricative systems. It ensures that engine oil is effectively distributed to moving parts, reducing friction and wear. The seal is also used in the Idler Gear setups to maintain oil levels and prevent leaks that could lead to inefficient gear operation.

Cooling System Efficiency

The Cooler and Oil Assembly Cooler systems benefit from the O-Ring Seal by ensuring that coolant flows smoothly without leakage. This is essential for maintaining the engine’s temperature within operational limits, thereby enhancing overall engine efficiency and longevity.

Specialized Applications

In more specialized components like the Prechamber Bits and QSV (Quick Service Valve), the O-Ring Seal is used to maintain the integrity of fuel and air mixtures. This is particularly important in high-performance engines where precise control of these mixtures is necessary for optimal combustion.

Use in the D67 Engine

For the D67 Engine, the O-Ring Seal is employed in various critical junctions to ensure that all fluid systems—whether they be for cooling, lubrication, or fuel delivery—operate without interruption. This consistent sealing capability is fundamental to the engine’s reliability and performance.

Conclusion

The Cummins 3421317 O-Ring Seal is a critical component in the maintenance and operation of commercial truck engines. Its role in ensuring tight seals across various systems—from fuel and lubrication to cooling and turbocharger operations—underscores its importance in maintaining engine efficiency and reliability. Proper installation, regular maintenance, and prompt troubleshooting of common issues are essential practices to maximize the effectiveness of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.