This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3421642 O-Ring Seal, manufactured by Cummins, is a critical component utilized in commercial trucks. It plays a significant role in maintaining the integrity of various systems within these vehicles by preventing leaks and ensuring efficient operation of mechanical systems.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket with a circular cross-section, designed to create a seal between two or more parts. It functions by being compressed within a groove, forming a barrier that prevents the passage of fluids or gases. O-Ring Seals are typically made from elastomers, which provide flexibility and resilience. Common materials include nitrile rubber, silicone, and fluorocarbon, each offering distinct properties such as resistance to chemicals, temperature, and abrasion 1.

Purpose of the 3421642 O-Ring Seal in Truck Operations

This Cummins part is employed in specific systems within a truck to ensure the sealing of connections and joints. It is associated with components where fluid or gas containment is necessary, contributing to the overall functionality and efficiency of these systems.

Key Features of the 3421642 O-Ring Seal

The 3421642 is characterized by its precise design and material composition. It is crafted to meet the demanding requirements of commercial truck applications, featuring attributes that enhance its performance and durability in varied operating conditions.

Benefits of Using the 3421642 O-Ring Seal

Utilizing this part offers several advantages, including enhanced sealing efficiency, extended longevity, and resistance to environmental factors. Its application contributes to the reliability of the systems it is part of, ensuring consistent performance over time.

Installation and Maintenance Guidelines

Proper installation of the 3421642 involves careful handling to avoid damage. It should be seated correctly within the designated groove to ensure an effective seal. Maintenance practices include regular inspections for signs of wear or damage, and replacement according to manufacturer guidelines to maintain optimal performance.

Troubleshooting Common Issues

Common issues with O-Ring Seals, such as leaks or failures, can often be traced to installation errors or environmental factors. Troubleshooting steps may involve inspecting the seal for damage, ensuring proper seating, and addressing any external factors that may affect its performance. Corrective actions should be taken based on the specific issue identified.

Cummins: A Brief Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its wide range of products and commitment to quality and innovation. The company’s reputation is built on delivering reliable components that meet the rigorous demands of commercial vehicle applications.

Role of the 3421642 O-Ring Seal in Engine Systems

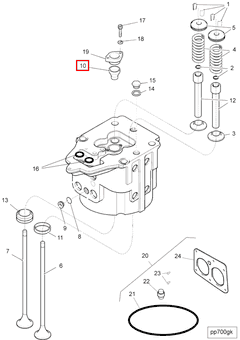

The 3421642 is instrumental in maintaining the integrity and efficiency of various engine components. In the Assembly Head Cylinder, it ensures a tight seal between the head and the cylinder, preventing coolant and combustion gases from leaking. This seal is equally important in the Assembly Valve and Assembly with Valves Head, where it helps maintain the pressure necessary for optimal valve operation.

Within the Cylinder Assembly Head and Cylinder Head, the O-Ring Seal plays a significant role in sealing the combustion chamber, ensuring that the fuel-air mixture is compressed effectively before ignition. In the Cylinder Head Overhaul Kit, it is often included to replace worn-out seals, restoring the head’s sealing capabilities.

The Cylinder Sub-Assembly Head relies on the O-Ring Seal to prevent any fluid or gas leakage that could compromise engine performance. Similarly, in the Head, Cylinder, and Head Assembly with Valves, the seal is vital for maintaining the structural integrity and operational efficiency of these components.

In the Head Cylinder Assembly and Head Cylinder Sub-Assembly, the O-Ring Seal is essential for sealing the interface between the head and the cylinder, ensuring that the combustion process is contained within the cylinder. The Head Gas Cylinder Assembly also benefits from the seal, as it helps in maintaining the pressure differentials necessary for efficient gas flow within the engine.

Lastly, in the Overhaul Kit, the O-Ring Seal is a key component that ensures all refurbished or replaced parts function as intended, providing a reliable seal across various interfaces within the engine system.

Conclusion

The 3421642 O-Ring Seal is a vital component in the maintenance and operation of commercial truck engines. Its precise design and material composition ensure it meets the demanding requirements of these applications, contributing to the reliability and efficiency of the systems it is part of.

-

Composite Materials Handbook Volume 4 Metal Matrix Composites, SAE International, 2013.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.