This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3422050 O-Ring Seal is designed to enhance the reliability and efficiency of commercial truck maintenance and operation. Cummins, a prominent name in the commercial vehicle industry, manufactures this part to meet the demanding requirements of heavy-duty applications.

Basic Concepts of O-Ring Seals

O-Ring Seals are elastomeric rings with a circular cross-section, used to create seals in various mechanical systems. They function by being compressed within a groove, forming a barrier that prevents the leakage of fluids and gases. These seals are versatile and can be found in a wide range of applications, from automotive to aerospace industries 1.

Purpose of the 3422050 O-Ring Seal in Truck Operation

This Cummins part plays a specific role in the operation of commercial trucks by ensuring the integrity of seals in various systems. It is applied in points where fluid or gas containment is required, supporting systems such as fuel lines, hydraulic systems, and engine components. Its function is to maintain system pressure and prevent leaks, contributing to the overall efficiency and safety of the truck.

Key Features of the 3422050 O-Ring Seal

The 3422050 is characterized by its robust design and material composition, which includes resistance to a variety of substances and operational temperature ranges. These features ensure the seal’s durability and effectiveness in withstanding the harsh conditions typical of commercial truck environments.

Benefits of Using the 3422050 O-Ring Seal

Utilizing this part offers several advantages, including enhanced system reliability, reduced maintenance requirements, and improved performance of truck components. Its design contributes to a more efficient operation of the truck’s systems, leading to potentially lower operational costs and increased uptime.

Installation Considerations

Proper installation of the 3422050 is vital for its performance and longevity. Guidelines recommend using appropriate tools and following specific procedures to ensure the seal is correctly positioned and compressed within its groove. Cummins provides detailed instructions to facilitate the installation process.

Troubleshooting Common Issues

Common issues with O-Ring Seals, including the 3422050, may involve leaks or failure to create a proper seal. Diagnostic steps often include inspecting the seal for signs of wear or damage and checking the groove for debris or improper sizing. Solutions may range from cleaning and re-installation to replacement of the seal.

Maintenance Tips

Regular inspection and maintenance of the 3422050 are recommended to prevent failures and extend its service life. Signs of wear, such as cracking or hardening, indicate the need for replacement. Adhering to a maintenance schedule helps ensure the seal continues to perform its function effectively.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a broad product range, Cummins is renowned for its quality and reliability in the commercial vehicle industry. This reputation underscores the trust in components like the 3422050 O-Ring Seal 2.

Compatibility with Engine Models

The 3422050 is designed to fit seamlessly with several engine models, ensuring optimal performance and reliability. This seal is integral in maintaining the integrity of the engine’s sealing system, preventing leaks and ensuring efficient operation.

QSV81G and QSV91G Engines

This part is compatible with the QSV81G and QSV91G engines. These engines are known for their robust design and high performance, often used in demanding applications. The seal ensures that the engine’s internal components remain protected from contaminants and external elements, contributing to the longevity and efficiency of these engines.

QSW/QSV82 Engines

The QSW/QSV82 engines also benefit from the use of the Cummins O-Ring Seal part 3422050. This seal is engineered to fit precisely within the engine’s design, providing a reliable barrier against leaks and ensuring that the engine operates at peak performance. The compatibility of this seal with the QSW/QSV82 engines highlights its versatility and effectiveness across different engine models.

QSW27 and QSW36 Engines

For the QSW27 and QSW36 engines, the O-Ring Seal part 3422050 is an essential component. These engines are designed for specific applications, and the seal plays a crucial role in maintaining their operational integrity. By fitting perfectly within the engine’s design, the seal helps to prevent leaks and ensures that the engine runs smoothly and efficiently.

QSW73 Engines

Lastly, the QSW73 engines are also compatible with the Cummins O-Ring Seal part 3422050. This seal is designed to meet the specific requirements of the QSW73 engines, providing a reliable and durable sealing solution. Its compatibility with this engine model underscores its importance in maintaining the engine’s performance and reliability.

Role of Part 3422050 O-Ring Seal in Engine Systems

The O-Ring Seal, identified by part number 3422050, is an essential component in ensuring the integrity and efficiency of various engine systems. Its application spans across multiple assemblies and sub-assemblies, providing reliable sealing solutions to prevent leaks and maintain system performance.

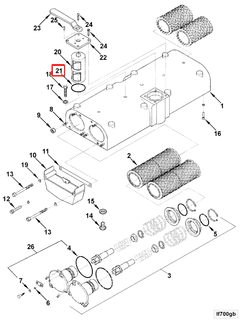

Aftercooler Assembly and Sub-Assembly Covers

In the aftercooler assembly cover and aftercooler sub-assembly cover, the O-Ring Seal plays a significant role in sealing the interfaces between components. This ensures that the cooling process of the compressed air is efficient, without any loss of coolant or air. The seal helps in maintaining the pressure and temperature differentials necessary for optimal aftercooling.

Air Outlet Assembly and Pipe

For the air outlet assembly pipe and air outlet pipe, the O-Ring Seal is used at connection points to prevent air leaks. This is vital for maintaining the correct airflow from the turbocharger to the intake manifold, ensuring that the engine receives the necessary volume of air for combustion.

Turbocharger Arrangement and Assembly

Within the turbocharger arrangement and assembly, the O-Ring Seal is employed to seal the connections between the turbocharger and its related components. This includes sealing the oil feed lines (LOM Fee and LOM FWE) to the turbocharger, ensuring that lubricating oil is delivered without leakage, which is essential for the turbocharger’s bearing and overall performance.

Charge Air Cooler Assembly and Cooler

In the charge air cooler assembly and cooler, the O-Ring Seal is critical for sealing the connections within the heat exchanger assembly. This ensures that the charge air is effectively cooled before entering the engine, contributing to better engine efficiency and performance.

Intake Assembly Manifold

The intake assembly manifold utilizes the O-Ring Seal at various connection points to ensure a tight seal. This is important for maintaining the correct air-fuel mixture and preventing any air leaks that could affect engine performance.

Lubricating Oil Assembly and Related Components

Across the lubricating oil assembly, lubricating oil assembly filter, lubricating oil filter, lubricating oil filter housing, and lubricating oil module assembly, the O-Ring Seal is used to ensure that oil pathways are sealed. This prevents oil leaks and ensures that the engine receives a consistent supply of clean oil for lubrication.

Full Flow Oil Filter and Housing

In the full flow oil filter and its housing, the O-Ring Seal is used to create a secure connection between the filter and the housing. This ensures that oil passes through the filter without bypassing, which is essential for maintaining oil cleanliness and engine longevity.

Oil Filter Assembly Housing

The oil filter assembly housing also relies on the O-Ring Seal to ensure a leak-free connection. This is crucial for the effective operation of the full flow oil filter, ensuring that oil is filtered properly before circulating through the engine.

Seal Kit

The seal kit often includes O-Ring Seals as part of its components, designed to replace worn or damaged seals across various engine systems. This ensures that all sealed connections within the engine are maintained, contributing to the overall reliability and performance of the engine.

Conclusion

The Cummins 3422050 O-Ring Seal is a critical component for maintaining the integrity and efficiency of commercial truck and engine systems. Its robust design, compatibility with various engine models, and role in preventing leaks across multiple assemblies underscore its importance in ensuring reliable and efficient operation.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.