This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3423800 O-Ring Seal is a component designed to ensure the integrity of fluid systems within commercial trucks. Its role is to provide a reliable seal in various applications, contributing to the efficient operation of the vehicle. Understanding its purpose and significance can help maintain the performance and longevity of truck systems.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket with a circular cross-section, designed to create a seal between two or more parts. It functions by being compressed within a groove, which allows it to form a tight seal against the mating surface. O-Ring Seals are commonly used in mechanical systems to prevent leaks of fluids and gases, ensuring the system operates within specified parameters 1.

Purpose of the Cummins 3423800 O-Ring Seal

The Cummins 3423800 O-Ring Seal plays a specific role in the operation of a truck by ensuring that fluid systems remain sealed. It is typically located in areas where fluid transfer occurs, such as within the engine or transmission systems. Its function is to prevent leaks and maintain system pressure, which is vital for the proper operation of the truck 2.

Key Features

The Cummins 3423800 O-Ring Seal is characterized by its material composition, which is often made from durable elastomers to withstand high temperatures and pressures. Its design includes precise dimensions to ensure a snug fit within the designated grooves. These features contribute to its performance by providing a reliable seal that can endure the demanding conditions of commercial truck operations 3.

Benefits

The Cummins 3423800 O-Ring Seal offers several benefits, including improved sealing efficiency which helps in maintaining system integrity. Its durability ensures longevity, reducing the frequency of replacements. Additionally, the seal contributes to overall system reliability by preventing leaks that could lead to system failures or inefficiencies.

Installation Process

To install the Cummins 3423800 O-Ring Seal, begin by ensuring the groove is clean and free of debris. Lubricate the O-Ring with a compatible lubricant to facilitate installation. Carefully place the O-Ring into the groove, ensuring it is seated properly without twists or folds. Once installed, check for proper seating and ensure there is no damage to the O-Ring.

Troubleshooting Common Issues

Common issues with O-Ring Seals include leaks or wear. If a leak is detected, inspect the O-Ring for signs of damage or improper seating. Wear can be identified by examining the O-Ring for cracks or deformities. Addressing these issues promptly can prevent further system complications.

Maintenance Tips

Regular maintenance of the Cummins 3423800 O-Ring Seal involves periodic inspection for signs of wear or damage. Cleaning the groove and the O-Ring during maintenance intervals can prevent contamination that may lead to seal failure. Additionally, ensuring that the system operates within specified parameters can prolong the life of the O-Ring Seal.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves commercial, industrial, and automotive markets. The company is committed to advancing technology and providing reliable solutions for its customers.

Cummins O-Ring Seal Part 3423800 in QSV81G and QSV91G Engines

The Cummins O-Ring Seal part number 3423800 is a critical component in the QSV81G and QSV91G engines. This seal is designed to provide a reliable barrier against leaks, ensuring the integrity of the engine’s internal systems. Its placement is crucial for maintaining the engine’s performance and longevity.

In the QSV81G engine, the O-Ring Seal part 3423800 is typically used in areas where there is a need to prevent fluid or gas from escaping. This could include connections between various engine components, such as the fuel injectors, oil lines, or coolant passages. The seal’s design allows it to conform to the surfaces it contacts, creating a tight seal that can withstand the pressures and temperatures found within the engine.

Similarly, in the QSV91G engine, the O-Ring Seal part 3423800 serves the same essential function. Its role is to maintain the seal in critical areas where leaks could lead to significant performance issues or engine damage. The seal’s material is chosen for its durability and resistance to the harsh conditions inside the engine, ensuring it can perform reliably over extended periods.

Both engines benefit from the precision engineering of the O-Ring Seal part 3423800, which is manufactured to meet stringent quality standards. This ensures that the seal will perform consistently, providing the necessary barrier to keep the engine operating efficiently.

Role of Part 3423800 O-Ring Seal in Engine Components

The part 3423800 O-Ring Seal is instrumental in ensuring the integrity and efficiency of various engine components. Its application spans across several key assemblies and kits, providing essential sealing functions that contribute to the overall performance and reliability of the engine.

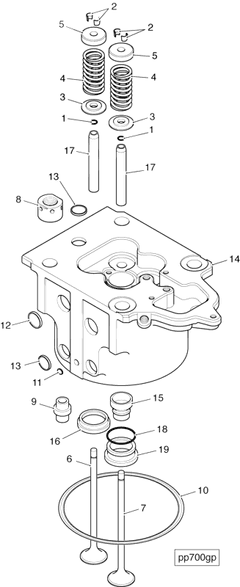

Assembly Head Cylinder

In the assembly head cylinder, the O-Ring Seal is utilized to create a tight seal between the cylinder head and the engine block. This seal is vital for maintaining compression within the combustion chamber, ensuring that the air-fuel mixture is efficiently combusted without any leaks. The seal also prevents coolant or oil from entering the combustion chamber, which could lead to contamination and reduced engine performance.

Assembly with Valves Head

When integrated into the assembly with valves head, the O-Ring Seal plays a role in sealing the passages that carry fluids or gases to and from the valve components. This ensures that the valves operate within the designed parameters, without any interference from external fluids or gases. Proper sealing here is essential for maintaining the precision and timing of valve operations, which directly impacts engine efficiency and power output.

Cylinder Assembly Head

Within the cylinder assembly head, the O-Ring Seal is employed to secure the connections between various sub-components. This includes sealing the interfaces between the cylinder head and any attached sensors or emission control devices. Effective sealing in this area ensures that the data collected by these sensors is accurate, and that emission controls function as intended, contributing to both performance and environmental compliance.

Cylinder Head

In the cylinder head itself, the O-Ring Seal is often used around gaskets or between the head and any ancillary components such as fuel injectors or spark plugs. This application ensures that the combustion process is contained within the cylinder, maximizing efficiency and preventing any potential damage to surrounding components from stray combustion events.

Cylinder Head Overhaul Kit

In a cylinder head overhaul kit, the O-Ring Seal is a common component used to replace worn or damaged seals during a rebuild. Its inclusion in the kit ensures that all critical sealing points are addressed, restoring the cylinder head to its original sealing efficiency and performance levels. This is particularly important in maintaining the longevity and reliability of the engine post-overhaul.

Mounting Insert

The O-Ring Seal is also utilized in conjunction with mounting inserts, where it helps to secure the cylinder head to the engine block. This application ensures that there is no movement or misalignment between these critical components, which could otherwise lead to leaks or reduced efficiency.

Overhaul Kit

Finally, in a comprehensive overhaul kit, the O-Ring Seal is a fundamental component that addresses multiple sealing points throughout the engine. Its role in this kit is to ensure that all connections and interfaces are properly sealed, contributing to the overall success and durability of the engine rebuild.

Conclusion

The Cummins 3423800 O-Ring Seal is a vital component in maintaining the integrity and efficiency of fluid systems within commercial trucks. Its precise design and durable material composition ensure reliable sealing across various engine components, contributing to the overall performance and longevity of the vehicle. Regular maintenance and prompt troubleshooting of common issues are essential to maximize the benefits of this Cummins part.

-

Eret, Angelina. Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature, 2024.

↩ -

Quigley, Jon M. SAE International’s Dictionary of Testing, Verification and Validation. SAE International, 2023.

↩ -

Lakshminarayanan, P A, and Yogesh V Aghav. Modelling Diesel Combustion. Springer Science, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.