This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3425818 O-Ring Seal is a critical component designed to maintain the integrity of seals within commercial trucks. It prevents leaks and ensures system efficiency by containing fluids and gases within their designated pathways 1.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a circular cross-section gasket designed to create a seal between two or more parts. It functions by being compressed within a groove, forming a tight seal against the mating surface. O-Ring Seals are essential in mechanical systems to prevent fluid and gas leakage and to exclude contaminants from sensitive areas 2.

Role of the 3425818 O-Ring Seal in Truck Operation

This Cummins part ensures the integrity of seals in various truck systems, such as the fuel system or hydraulic systems. It is placed in grooves where two surfaces meet, creating a barrier that prevents the escape of fluids or gases under pressure. This seal is vital for maintaining system pressure and efficiency 3.

Key Features of the 3425818 O-Ring Seal

The 3425818 O-Ring Seal is made from durable elastomers that can withstand a range of temperatures and pressures. Its design provides a snug fit within designated grooves and is engineered to resist wear and degradation over time. These features contribute to the seal’s performance and longevity.

Benefits of Using the 3425818 O-Ring Seal

Utilizing this part offers several benefits, including enhanced sealing efficiency, which helps maintain system integrity. Its durability ensures a longer service life, reducing the frequency of replacements. Additionally, the seal’s resistance to various operating conditions, such as temperature fluctuations and exposure to chemicals, makes it a reliable component in demanding environments.

Installation Considerations

Proper installation of the 3425818 O-Ring Seal is vital for its performance and longevity. It should be installed in a clean groove free of debris to ensure a proper seal. Care must be taken to avoid damaging the O-Ring during installation, as this can compromise its sealing capabilities. Following manufacturer guidelines for torque and alignment will help ensure optimal performance.

Common Issues and Troubleshooting

O-Ring Seals may encounter issues such as wear, deformation, or failure due to exposure to extreme conditions or improper installation. Signs of these issues include leaks or a decrease in system performance. Troubleshooting steps may involve inspecting the seal for damage, checking the groove for cleanliness and proper sizing, and ensuring that the seal is correctly installed.

Maintenance Tips

To maintain the 3425818 O-Ring Seal, regular inspection intervals should be established to check for signs of wear or damage. Cleaning the seal and its groove with appropriate solvents can prevent contamination that may lead to failure. Replacement should be considered if the seal shows signs of degradation or if system performance is compromised.

Cummins: A Brief Overview

Cummins Inc. is a corporation known for designing, manufacturing, and distributing engines and related technologies. With a history spanning several decades, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company offers a wide range of products, including engines, filtration systems, and aftermarket parts, all designed to meet the rigorous demands of commercial transportation.

Compatibility with Cummins Engines

This O-Ring Seal is designed to fit seamlessly with a variety of Cummins engine models, including the QSV81G, QSV91G, QSW/QSV82, QSW27, QSW36, and QSW73. It ensures a tight seal to prevent any leaks or fluid loss, maintaining the integrity of the engine’s sealing system 3.

Role of Part 3425818 O-Ring Seal in Engine Systems

The 3425818 O-Ring Seal is integral to the functionality and efficiency of various engine components. Its primary role is to ensure a tight seal, preventing leaks and maintaining system integrity.

Coolant Heater Starting Aid and Assembly

In the coolant heater starting aid and the coolant heater assembly, the O-Ring Seal creates a secure seal around the connections and joints, preventing coolant leakage and ensuring efficient heater function during cold starts.

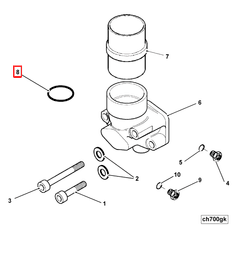

Thermostat Housing Arrangement

Within the thermostat housing arrangement, the O-Ring Seal is critical for sealing the thermostat housing to the engine block or cylinder head. This prevents coolant from escaping, ensuring that the thermostat can regulate engine temperature effectively.

Preheater Plug-In Assembly

In the preheater plug-in assembly, the O-Ring Seal ensures that the preheater unit is securely sealed to the engine block, preventing any coolant or oil leaks that could impair the preheater’s ability to warm the engine components before start-up.

Engine Assembly Heater

For the engine assembly heater, the O-Ring Seal creates a reliable seal around the heater’s connections to the engine, ensuring that the heater can operate without leaks, providing consistent warmth to the engine components.

Governor and Hydraulic Assemblies

In the governor and hydraulic assemblies, the O-Ring Seal is employed to seal the various connections and joints, maintaining the integrity of the hydraulic system and ensuring that fluid leaks are minimized.

Seal Kit and Water Transfer Connection Gasket

The O-Ring Seal is often included in seal kits to replace worn or damaged seals in various engine components. In the water transfer connection gasket applications, the O-Ring Seal ensures that the connection between different coolant passages remains leak-free.

Conclusion

The Cummins 3425818 O-Ring Seal plays a significant role in ensuring the reliability and efficiency of engine components by providing essential seals that prevent leaks and maintain system integrity. Proper installation, regular maintenance, and understanding its role in various engine systems are crucial for optimal performance and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.