This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3429850 O-Ring Seal is a critical component designed to maintain the integrity of fluid systems within commercial trucks. Its primary function is to prevent leaks and maintain system pressure, which is essential for the efficiency and reliability of truck operations 1.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket with a circular cross-section, designed to create a seal between two or more parts. It functions by deforming slightly when compressed, filling the gap between mating surfaces to prevent fluid or gas leakage. O-Ring Seals are widely used in various mechanical systems due to their simplicity, effectiveness, and versatility in sealing applications 2.

Purpose of the Cummins 3429850 O-Ring Seal

The Cummins 3429850 O-Ring Seal is specifically engineered to serve within the engine or other fluid systems of a truck. It maintains the seal at connection points, ensuring that fluids such as oil, coolant, or fuel do not escape, which is vital for the proper operation and longevity of the truck’s systems 3.

Key Features

The Cummins 3429850 O-Ring Seal is characterized by its material composition, typically made from durable elastomers that offer resistance to a wide range of temperatures and chemicals. Its design specifications are tailored to fit precisely within the designated applications, enhancing its sealing performance and durability under various operating conditions 4.

Benefits

Utilizing the Cummins 3429850 O-Ring Seal offers several advantages, including improved sealing efficiency, which helps in maintaining system pressure and preventing leaks. Its durability ensures longevity, reducing the frequency of replacements. Additionally, it exhibits resistance to various operating conditions, making it a reliable component in demanding environments 5.

Installation Process

To install the Cummins 3429850 O-Ring Seal, first, ensure the mating surfaces are clean and free of debris. Lubricate the O-Ring lightly to facilitate installation without damage. Carefully place the O-Ring into the groove, ensuring it is seated correctly. Assemble the components, applying even pressure to avoid distorting the O-Ring. Verify the seal by checking for leaks after the system is pressurized 6.

Troubleshooting Common Issues

Common issues with O-Ring Seals include leaks, which may arise from improper installation, degradation due to age or exposure to incompatible fluids, or physical damage. To address these issues, inspect the O-Ring for signs of wear or damage, ensure correct installation, and verify compatibility with system fluids. Replacement may be necessary if the O-Ring is compromised 7.

Maintenance Tips

Regular maintenance of the Cummins 3429850 O-Ring Seal involves periodic inspection for signs of wear, such as cracking or hardening, which may indicate the need for replacement. Establishing a routine inspection schedule can help identify issues before they lead to system failures. Additionally, adhering to recommended replacement intervals can ensure the seal’s effectiveness is maintained over time 8.

Compatibility

The Cummins O-Ring Seal part number 3429850 is designed to fit seamlessly with a variety of Cummins engine models. This seal is crucial for maintaining the integrity of the engine’s sealing systems, ensuring that there are no leaks and that the engine operates efficiently.

Compatible Engines

- QSV81G, QSV91-G4 CM558/CM700 V102, QSV91G, QSW/QSV82, QSW27, QSW36, QSW73

This O-Ring Seal is engineered to fit perfectly within the specified dimensions and requirements of these engines. Its compatibility ensures that it can be used across multiple models without the need for modifications.

Grouping of Compatible Engines

- QSV Series: The QSV81G and QSV91G models are part of the QSV series, which are known for their robust design and reliability. The O-Ring Seal part 3429850 is specifically tailored to meet the sealing needs of these engines.

- QSW Series: The QSW/QSV82, QSW27, QSW36, and QSW73 engines are part of the QSW series. This series is designed for versatility and efficiency, and the O-Ring Seal part 3429850 is engineered to provide a tight, reliable seal in these engines.

- CM558/CM700 V102: This model, part of the CM series, is designed for high-performance applications. The O-Ring Seal part 3429850 is compatible with this model, ensuring that it can handle the demands of high-performance engines.

By ensuring that the O-Ring Seal part 3429850 is compatible with these engines, Cummins guarantees that the seal will perform optimally, providing a reliable barrier against leaks and maintaining the engine’s efficiency 9.

Role of Part 3429850 O-Ring Seal in Engine Systems

The 3429850 O-Ring Seal is an essential component in maintaining the integrity and efficiency of various engine systems. Its application spans across multiple components, ensuring optimal performance and longevity.

Integration with Cylinder Head Conversion Kit

When installed as part of a cylinder head conversion kit, the 3429850 O-Ring Seal plays a significant role in preventing coolant and oil leaks. This is vital for maintaining the proper lubrication and cooling of the engine, which directly impacts its overall performance and durability 10.

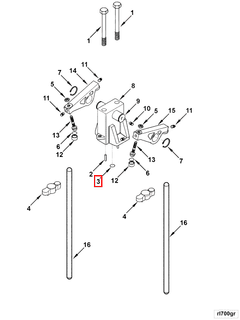

Functionality in Lever and Rocker Assemblies

In lever and rocker assemblies, the O-Ring Seal is used to create a tight seal between moving parts. This ensures that there is no unwanted fluid leakage, which could lead to decreased efficiency or potential damage to the engine components. The seal is particularly important in the lever assembly rocker and rocker assembly lever, where precise movement and minimal friction are required for optimal engine operation 11.

Application in Rocker Lever Assembly

The rocker lever assembly benefits from the 3429850 O-Ring Seal by ensuring that the interface between the rocker and the lever remains sealed. This prevents any lubricants from escaping, which is essential for the smooth operation of the valve train. A well-sealed system ensures that the rocker can move freely without resistance, contributing to better valve timing and engine performance 12.

Use in Lever Mounting Rocker

In the lever mounting rocker, the O-Ring Seal helps in securing the lever to the rocker, preventing any fluid leakage that might occur at the mounting points. This is important for maintaining the structural integrity of the assembly and ensuring that the lever can operate efficiently without any external contaminants affecting its movement 13.

Importance in Single Head Gasket Set

When incorporated into a single head gasket set, the 3429850 O-Ring Seal assists in creating a robust seal between the cylinder head and the engine block. This is fundamental in preventing coolant and oil from mixing, which can lead to engine overheating and reduced efficiency. The seal ensures that the combustion process remains contained, leading to better engine performance and reliability 14.

Conclusion

Overall, the 3429850 O-Ring Seal is a versatile component that enhances the functionality and reliability of various engine systems by ensuring proper sealing and preventing fluid leaks. Its compatibility with multiple Cummins engine models and its role in critical engine components make it an indispensable part of maintaining engine efficiency and performance.

-

Bennett, S. (2012). Modern Diesel Technology: Light Duty Diesels. Cengage Learning.

↩ -

Thompson, R. (2019). Automotive Maintenance: Light Repair. Cengage Learning.

↩ -

Hiereth, H., Prenninger, P., & Drexl, K. W. (2010). Charging the Internal Combustion Engine. Springer.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5467182.

↩ -

Bennett, S. (2012). Modern Diesel Technology: Light Duty Diesels. Cengage Learning.

↩ -

Thompson, R. (2019). Automotive Maintenance: Light Repair. Cengage Learning.

↩ -

Hiereth, H., Prenninger, P., & Drexl, K. W. (2010). Charging the Internal Combustion Engine. Springer.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5467182.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5467182.

↩ -

Bennett, S. (2012). Modern Diesel Technology: Light Duty Diesels. Cengage Learning.

↩ -

Thompson, R. (2019). Automotive Maintenance: Light Repair. Cengage Learning.

↩ -

Hiereth, H., Prenninger, P., & Drexl, K. W. (2010). Charging the Internal Combustion Engine. Springer.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5467182.

↩ -

Bennett, S. (2012). Modern Diesel Technology: Light Duty Diesels. Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.