This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

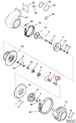

The Split Ring Seal 3527368, manufactured by Cummins, is a vital component in the commercial vehicle industry, contributing to the efficient and reliable performance of truck engines and transmissions.

Basic Concepts of Split Ring Seals

Split ring seals are mechanical components designed to create a seal between two surfaces, preventing the leakage of fluids or gases. They function by being compressed between the mating surfaces, which creates a barrier that inhibits the passage of substances. These seals are commonly used in various mechanical systems to ensure the integrity of fluid and gas pathways 1.

Purpose of the 3527368 Split Ring Seal in Truck Operations

This Cummins part plays a role in the operation of commercial trucks by providing a reliable seal in the engine or transmission system. Its function is to maintain the separation of different fluids or gases within the system, ensuring that they remain within their designated pathways. This helps in preserving the efficiency and performance of the truck’s engine and transmission 2.

Key Features of the 3527368 Split Ring Seal

The 3527368 Split Ring Seal is characterized by several primary features. It is typically made from durable materials that can withstand the high pressures and temperatures encountered in truck engines and transmissions. The design of the seal allows for flexibility and adaptability to various applications, ensuring a snug fit in different environments. Additionally, the manufacturing process may involve precision engineering to ensure the seal meets the stringent requirements of commercial vehicle operations 3.

Benefits of Using the 3527368 Split Ring Seal

Utilizing this part offers several advantages. It provides improved sealing efficiency, which contributes to the overall performance and reliability of the truck’s engine and transmission. The seal’s durability ensures long-term use, reducing the frequency of replacements and associated downtime. Furthermore, its use can lead to potential cost savings for fleet operators by minimizing the risk of leaks and the need for repairs 4.

Installation and Replacement Guidelines

Proper installation and replacement of the 3527368 Split Ring Seal involve several steps. It is important to ensure the mating surfaces are clean and free of debris before installation. The seal should be positioned correctly to ensure an effective seal is formed. During replacement, care should be taken to remove the old seal without damaging the surrounding components. Following manufacturer guidelines and best practices will help avoid common pitfalls such as improper seating or damage to the seal.

Troubleshooting Common Issues

Frequent problems associated with split ring seals may include leaks, wear, or damage. Diagnostic methods involve inspecting the seal and the mating surfaces for signs of wear or misalignment. Recommended solutions may include cleaning the surfaces, replacing the seal, or adjusting the components to ensure proper fit and function.

Maintenance Tips

Routine checks and maintenance practices are vital to ensure the longevity and effectiveness of the 3527368 Split Ring Seal. This includes regular inspections for signs of wear or damage, ensuring the seal remains in good condition. Lubrication may be required in some applications to facilitate the seal’s function. Adhering to recommended inspection and maintenance schedules will help maintain the seal’s performance and extend its lifespan.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial vehicle industry. The company’s commitment to excellence is reflected in its diverse product range and its continuous pursuit of technological advancements.

Compatibility with Engine Models

This Cummins part is designed to fit seamlessly with a variety of Cummins engine models, ensuring optimal performance and longevity. This seal is crucial for maintaining the integrity of the engine by preventing leaks and ensuring that moving parts operate smoothly.

K50 Series Engines

The K50 series engines benefit from the use of the 3527368 Split Ring Seal, which is engineered to fit perfectly within the engine’s design specifications. This seal is particularly important in maintaining the pressure and preventing fluid leakage in these engines.

QSK50 CM2150 MCRS and QSK50 CM2350 K108

For the QSK50 CM2150 MCRS and QSK50 CM2350 K108 engines, the 3527368 Split Ring Seal is a critical component. These engines, known for their robust performance, rely on this seal to maintain operational efficiency and prevent any form of fluid escape. The seal’s precision fit ensures that it can withstand the high pressures and temperatures typical of these engines.

QSK95 CM2350 K113

Similarly, the QSK95 CM2350 K113 engine also integrates the 3527368 Split Ring Seal effectively. This engine model, which is part of the Cummins QSK series, is designed for heavy-duty applications. The seal’s role in this engine is to provide a reliable barrier against leaks, ensuring that the engine operates at peak efficiency. The seal’s compatibility with this engine model is a testament to its design and manufacturing standards, which are tailored to meet the demands of high-performance engines.

Role of Part 3527368 Split Ring Seal in Engine Systems

This part is an essential component in various engine systems, particularly within the context of aftermarket turbochargers and core assemblies. Its primary function is to ensure a secure and leak-free connection between rotating and stationary parts, which is vital for maintaining the integrity and performance of the engine.

Integration with Aftermarket Turbochargers

In aftermarket turbochargers, the Split Ring Seal is utilized to create a tight seal between the turbine housing and the compressor housing. This seal prevents any unwanted air leaks, which can significantly impact the turbocharger’s efficiency and the overall performance of the engine. By ensuring that the pressurized air flows correctly through the system, the seal helps maintain optimal boost levels and enhances the turbocharger’s ability to deliver power.

Core Assembly Applications

Within the core assembly of a turbocharger, the Split Ring Seal plays a key role in sealing the connection between the turbine wheel and the compressor wheel. This is particularly important in high-performance applications where even the smallest leaks can lead to a noticeable drop in efficiency. The seal helps to maintain the precise balance required for the turbocharger to operate at peak performance, ensuring that the engine delivers the desired power output.

EBM-Parts and Performance Enhancements

For EBM-parts and performance-oriented turbochargers, the Split Ring Seal is often a component included in turbocharger repair kits and performance parts. Its role in these applications is to enhance the durability and reliability of the turbocharger. By providing a consistent and reliable seal, it allows for higher operating pressures and temperatures, which are common in performance-tuned engines. This results in improved throttle response, increased power, and better overall engine performance.

Turbocharger Kits and Repair

In turbocharger kits and repair scenarios, the Split Ring Seal is a component that ensures the turbocharger can be reassembled correctly after maintenance or repair. Its ease of installation and removal makes it a preferred choice for technicians performing repairs or upgrades. The seal’s ability to withstand high temperatures and pressures makes it an invaluable part of any turbocharger kit, ensuring that the repaired or upgraded turbocharger performs as expected.

Conclusion

The 3527368 Split Ring Seal by Cummins is a critical component in the maintenance and performance of commercial truck engines and transmissions. Its role in preventing leaks, ensuring efficient operation, and contributing to the longevity of engine systems underscores its importance in the commercial vehicle industry. Proper installation, maintenance, and understanding of its applications are essential for maximizing the benefits of this part.

-

Trzesniowski, Michael. The Complete Vehicle. Springer Nature, 2023.

↩ -

Arora, Shashank, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi. Heavyduty Electric Vehicles: From Concept to Reality. Elsevier, 2021.

↩ -

Lejda, Kazimierz, and Pawel Wos. Internal Combustion Engines. InTech, 2012.

↩ -

Lakshminarayanan, P. A., and Avinash Kumar Agarwal. Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.