3558938

O-Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3558938 O-Ring Seal is a component designed to ensure the integrity of seals in various systems within heavy-duty trucks. Its role is significant in maintaining the efficiency and reliability of truck operations by preventing leaks and ensuring proper system function 4.

Basic Concepts of O-Ring Seals

O-Ring seals are elastomeric rings with a circular cross-section, used to create seals between two or more parts. They operate by deforming under compression when installed in a groove, creating a seal that prevents the passage of fluids or gases. O-Rings are widely utilized in mechanical systems due to their simplicity, effectiveness, and versatility in various applications 2.

Purpose of the Cummins 3558938 O-Ring Seal

This Cummins part is specifically designed for use in heavy-duty truck applications. It plays a role in sealing connections in fuel systems, hydraulic systems, and other critical areas where fluid or gas containment is necessary. By ensuring these seals are intact, the O-Ring contributes to the overall efficiency and reliability of the truck’s systems 4.

Key Features

The Cummins 3558938 O-Ring Seal is characterized by its durable material composition, typically made from nitrile rubber, which offers resistance to oils, fuels, and various chemicals. Its design specifications include precise dimensions to fit specific grooves and applications, ensuring a snug fit and effective seal. Additionally, the seal may feature unique attributes such as anti-extrusion properties to enhance performance and longevity in demanding environments 1.

Benefits of Using the Cummins 3558938 O-Ring Seal

Utilizing this Cummins part offers several advantages. It contributes to improved system efficiency by maintaining seals and preventing leaks, which can lead to system failures or inefficiencies. The seal’s durability and resistance to various substances enhance its longevity, reducing the need for frequent replacements. Moreover, its reliable performance in demanding truck environments ensures consistent operation and contributes to the overall reliability of the vehicle 4.

Installation Considerations

Proper installation of this Cummins part is vital to ensure optimal performance and longevity. Guidelines for installation include ensuring the groove is clean and free of debris before inserting the O-Ring. Careful handling is recommended to avoid damaging the seal during installation. Following manufacturer specifications for groove dimensions and compression ratios is also important to achieve an effective seal 2.

Troubleshooting Common Issues

Common issues with O-Ring seals, such as leaks or failures, can often be traced to installation errors, material degradation, or environmental factors. Troubleshooting steps may include inspecting the seal for signs of wear or damage, checking the groove for proper dimensions and cleanliness, and ensuring the seal is correctly installed. Addressing these issues promptly can help maintain system integrity and prevent further complications 4.

Maintenance Tips

Regular maintenance of the Cummins 3558938 O-Ring Seal is recommended to prolong its service life and ensure continued system efficiency. Maintenance routines may include periodic inspections for signs of wear or damage, cleaning the seal and groove to remove contaminants, and replacing the seal according to manufacturer guidelines or when signs of degradation are observed. Adhering to these maintenance practices can help maintain the seal’s effectiveness and contribute to the overall reliability of the truck’s systems 4.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related technologies. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive and heavy-duty truck industry. The company’s extensive product range and commitment to customer satisfaction have made it a trusted name among professionals and enthusiasts alike 3.

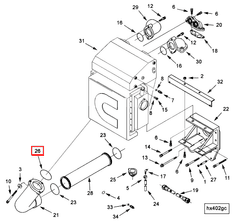

Role of Part 3558938 O-Ring Seal in Engine Systems

This Cummins part is instrumental in ensuring the integrity and efficiency of various engine systems. In the Fuel Filter assembly, this O-Ring Seal is positioned to create a tight seal between the filter housing and the filter element, preventing fuel leaks and maintaining consistent fuel pressure.

When integrated into the Fuel Filter Head, the O-Ring Seal ensures that the connection between the head and the fuel lines remains leak-free, which is essential for the proper functioning of the fuel delivery system.

At the Fuel Filter Location, whether it is in-line or part of a more complex assembly, the O-Ring Seal plays a key role in securing the filter housing to the engine or fuel system, thereby preventing any fuel escape that could lead to performance issues or safety hazards.

In the Heat Exchanger system, the O-Ring Seal is used to seal the connections between the heat exchanger components, ensuring that the transfer of heat between fluids occurs efficiently without any loss of fluid.

For the Heat Exchanger Mounting, the O-Ring Seal helps in securing the heat exchanger to its mounting brackets, providing a stable and leak-proof installation.

The Leak Test Kit, which is used to check for leaks in various engine systems, often incorporates O-Ring Seals to ensure that the test apparatus itself does not leak, providing accurate test results.

In conjunction with the Leak Test Plate and Leak Test Plug, the O-Ring Seal ensures that these components fit snugly into the engine system being tested, allowing for precise detection of leaks.

Lastly, within the Lower Engine Gasket Kit, the O-Ring Seal is utilized to ensure that the lower portions of the engine, such as the oil pan or sump, are sealed properly, preventing oil leaks and maintaining the engine’s lubrication system integrity 4.

Conclusion

The Cummins 3558938 O-Ring Seal is a vital component in maintaining the efficiency and reliability of heavy-duty truck systems. Its durable construction, precise fit, and resistance to various substances make it an essential part for sealing connections in fuel, hydraulic, and other critical systems. Proper installation, regular maintenance, and prompt troubleshooting of common issues are key to ensuring the longevity and effectiveness of this Cummins part, contributing to the overall performance and safety of the vehicle.

-

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩ -

Hilgers, M. (2023). Electrical Systems and Mechatronics, Second Edition. Springer Vieweg.

↩ ↩ -

Peters, G., & Peters, B. J. (2002). Automobile Vehicle Safety. CRC Press.

↩ -

Thompson, R. (2019). Automotive Maintenance: Light Repair. Cengage Learning.

↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.