This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3631755 O-Ring Seal is a component designed to ensure the integrity of seals within commercial truck systems. Its role is significant in maintaining the efficiency and reliability of truck operations, particularly in environments where durability and performance are paramount.

Basic Concepts of O-Ring Seals

O-Ring Seals are circular elastomeric rings used to create a seal between two or more mating surfaces. They function by deforming under compression to fill the gap between the surfaces, thereby preventing the leakage of fluids or gases. O-Ring Seals are widely utilized in various mechanical systems due to their simplicity, effectiveness, and versatility in sealing applications 1.

Purpose of the Cummins 3631755 O-Ring Seal

This Cummins part is specifically designed to play a role in the sealing mechanisms of truck components. It is associated with systems where fluid or gas containment is necessary, such as in engine compartments, transmission systems, and hydraulic circuits. By providing a reliable seal, it helps maintain system pressure and prevent leaks, which can lead to performance issues or component damage.

Key Features

This part is characterized by several key features that make it suitable for heavy-duty applications. These include a durable material composition that resists wear and tear, as well as design specifications that ensure a snug fit within the intended application. The seal is engineered to withstand a range of operating conditions, including temperature variations and exposure to various fluids.

Benefits

Utilizing the Cummins 3631755 O-Ring Seal offers several advantages. It provides improved sealing efficiency, which contributes to the overall performance and reliability of the truck’s systems. The seal’s longevity ensures that it can endure the rigors of heavy-duty use, reducing the frequency of replacements. Additionally, its resistance to various operating conditions makes it a robust choice for commercial truck applications 2.

Installation Considerations

Proper installation of this Cummins part is vital to ensure optimal performance and longevity. Guidelines for installation include ensuring the mating surfaces are clean and free of debris, using the correct amount of lubrication to facilitate seating, and avoiding over-compression of the seal, which can lead to premature failure.

Troubleshooting Common Issues

Common issues with O-Ring Seals can include leaks, extrusion, or damage from improper installation. To diagnose these problems, one should inspect the seal for signs of wear or deformation, check the mating surfaces for irregularities, and ensure that the seal is correctly seated. Resolution may involve cleaning or replacing the seal, as well as addressing any underlying issues with the mating surfaces or system pressure.

Maintenance Tips

Regular maintenance of the Cummins 3631755 O-Ring Seal involves inspection routines to check for signs of wear or damage. Cleaning procedures should be performed to remove any contaminants that could affect the seal’s performance. Replacement guidelines suggest that the seal should be inspected during routine maintenance intervals and replaced if any signs of degradation are present.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes a variety of components and systems designed to enhance the performance and reliability of commercial vehicles.

O-Ring Seal 3631755 Compatibility with Cummins Engines

The O-Ring Seal 3631755, manufactured by Cummins, is a critical component designed to ensure the integrity of various engine systems. This seal is compatible with several Cummins engine models, providing a reliable barrier against leaks and maintaining system pressure. Below is a detailed overview of its compatibility with specific engine types.

QSK45 CM500 and QSK60 CM500

The O-Ring Seal 3631755 is suitable for use in both the QSK45 CM500 and QSK60 CM500 engines. These engines are part of Cummins’ QSK series, known for their robust performance and reliability in heavy-duty applications. The seal’s design ensures it can withstand the high pressures and temperatures typical of these engines, providing a dependable seal in demanding conditions.

QSK60 CM850 MCRS and QSK60G

For the QSK60 CM850 MCRS and QSK60G engines, the O-Ring Seal 3631755 is equally essential. These engines are designed for marine applications, where durability and resistance to harsh environments are paramount. The seal’s material and construction are optimized to handle the unique challenges posed by marine environments, including exposure to saltwater and varying temperatures.

QSK78 CM500

The QSK78 CM500 engine also benefits from the use of the O-Ring Seal 3631755. This engine is part of Cummins’ lineup designed for high-power applications, often found in industrial and power generation sectors. The seal’s ability to maintain a tight fit under high pressure and temperature conditions is crucial for the engine’s performance and longevity.

QSK95 CM2350 K111 and QSK95 CM2350 K113

Finally, the O-Ring Seal 3631755 is compatible with the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines. These engines are part of Cummins’ advanced series, designed for heavy-duty applications requiring exceptional power and efficiency. The seal’s precision fit and durability make it an ideal choice for these high-performance engines, ensuring optimal sealing and system integrity.

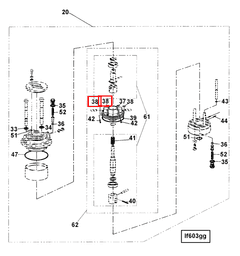

Role of Part 3631755 O-Ring Seal in Engine Systems

This part is instrumental in maintaining the integrity and efficiency of various engine systems. Its application spans across several components, ensuring optimal performance and longevity.

Full Flow Oil Filter

In the full flow oil filter system, the O-Ring Seal is positioned to create a tight seal between the filter and the engine block or filter housing. This seal prevents oil leaks and ensures that the oil flows through the filter media without bypassing, which is essential for effective filtration and contaminant removal.

Lubricating Oil System

Within the lubricating oil system, the O-Ring Seal is utilized in the connections between the oil pump, galleries, and passages. It ensures that the lubricating oil is delivered under pressure to all moving parts without any loss, thereby maintaining consistent lubrication and reducing wear.

Hydraulic Kit

In hydraulic kits, the O-Ring Seal is critical for maintaining pressure integrity. It is used in the connections between hydraulic components such as pumps, valves, and actuators. The seal prevents hydraulic fluid leaks, ensuring that the system operates with the required pressure and efficiency.

Lubricating Oil Filter

For the lubricating oil filter, the O-Ring Seal is employed at the interface between the filter element and the filter housing. This ensures that the oil passes through the filter media and not around it, enhancing the filtration process and protecting engine components from abrasive particles.

Lubricating Oil Filter Head

In the lubricating oil filter head, the O-Ring Seal is used to secure the filter element in place. It creates a barrier that prevents oil from leaking out while allowing it to flow through the filter, thus maintaining the cleanliness of the lubricating oil.

Lubricating Oil Filter Kit

Within a lubricating oil filter kit, the O-Ring Seal is a common component in various connections and interfaces. It ensures that all parts of the kit—including the filter housing, bypass valve, and relief valve—are sealed properly. This integrity is vital for the kit’s overall performance in filtering and maintaining the quality of the lubricating oil.

Conclusion

The Cummins 3631755 O-Ring Seal plays a vital role in the maintenance and efficiency of commercial truck systems. Its design and features make it suitable for heavy-duty applications, ensuring reliable sealing across various engine components and systems. Proper installation, regular maintenance, and troubleshooting common issues are essential for maximizing the performance and longevity of this critical component.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.