3633001

Oring Seal

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3633001 O-Ring Seal is a critical component designed to maintain the integrity of seals within commercial truck systems. It plays a significant role in preventing leaks and ensuring systems operate under the correct pressure conditions, which is vital for the overall performance and longevity of the vehicle 1.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a torus-shaped gasket designed to create a seal between two or more parts by being compressed within a groove. This creates a barrier that prevents the passage of fluids or gases. O-Ring Seals are widely used in mechanical systems due to their simplicity, effectiveness, and versatility. They are commonly manufactured from materials such as nitrile rubber, silicone, and fluorocarbon, each offering different properties like resistance to chemicals, temperature, and pressure 2.

Purpose of the Cummins 3633001 O-Ring Seal

The Cummins 3633001 O-Ring Seal ensures the sealing integrity of certain components or systems in trucks. It is associated with critical systems where fluid or gas containment is necessary for optimal performance. By maintaining a reliable seal, it contributes to the functionality and efficiency of these systems, ensuring they operate under the intended conditions without leaks or pressure loss 3.

Key Features

The Cummins 3633001 O-Ring Seal is characterized by its precise design and material composition, tailored to meet the demanding conditions of commercial truck environments. Its material is chosen for its durability, resistance to wear and tear, and compatibility with the specific fluids or gases it will encounter. These features enhance its performance and contribute to its longevity in challenging operational conditions.

Benefits

Using the Cummins 3633001 O-Ring Seal offers several advantages, including improved sealing efficiency, which helps in maintaining system pressure and preventing leaks. Its durability ensures long-term performance, reducing the need for frequent replacements. Additionally, its resistance to various environmental factors and compatibility with specific truck models or engine types make it a reliable choice for commercial truck maintenance.

Installation and Replacement Guidelines

Proper installation and replacement of the Cummins 3633001 O-Ring Seal involve several steps to ensure optimal performance and longevity. It is important to follow manufacturer guidelines for installation, which may include cleaning the groove, lubricating the O-Ring, and ensuring it is seated correctly without twists or kinks. Replacement should be considered when signs of wear or failure are observed, following similar installation practices to maintain seal integrity.

Troubleshooting Common Issues

Common issues with O-Ring Seals, including the Cummins 3633001, may involve leaks, wear, or failure. Diagnostic methods can include visual inspection for physical damage, checking for leaks under operating conditions, and assessing system performance. Solutions may range from simple replacements to addressing underlying issues that contribute to seal failure, such as misalignment or contamination.

Maintenance Tips

Regular maintenance of the Cummins 3633001 O-Ring Seal is key to ensuring its continued effective operation. This includes routine inspections for signs of wear or damage, cleaning the seal and its groove to remove contaminants, and following manufacturer recommendations for replacement intervals. Proper maintenance helps in identifying potential issues before they lead to system failure.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality and innovation. The company’s extensive product range and focus on meeting the needs of its customers underscore its position as a leader in the industry.

Cummins Engine Part 3633001 O-Ring Seal Compatibility

The O-Ring Seal part number 3633001 by Cummins is designed to ensure a secure seal in various engine applications. This seal is compatible with several Cummins engine models, providing essential sealing properties to maintain engine efficiency and performance.

QSK45 CM500 and QSK60 CM500 Engines

The O-Ring Seal part 3633001 is integral to the QSK45 CM500 and QSK60 CM500 engines. These engines are part of Cummins’ QSK series, known for their robust design and reliability in demanding applications. The seal ensures that critical engine components remain sealed, preventing leaks and maintaining the necessary pressure levels.

QSK60 CM850 MCRS and QSK60G Engines

The O-Ring Seal part 3633001 also fits the QSK60 CM850 MCRS and QSK60G engines. These engines are equipped with advanced features and technologies to deliver high performance and efficiency. The seal plays a role in these engines by ensuring that all moving parts and connections are properly sealed, which is vital for the longevity and optimal operation of the engine.

QSK78 CM500 Engine

The QSK78 CM500 engine is another model that benefits from the O-Ring Seal part 3633001. This engine is designed for heavy-duty applications, requiring a reliable sealing solution to withstand the rigors of continuous operation. The seal helps maintain the integrity of the engine’s sealing system, ensuring that it operates efficiently and reliably under various conditions.

Each of these engines relies on the O-Ring Seal part 3633001 to maintain proper sealing, which is essential for their overall performance and durability.

Role of Part 3633001 O-Ring Seal in Engine Systems

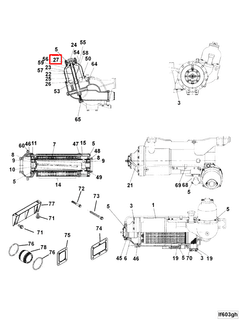

The part 3633001 O-Ring Seal is instrumental in maintaining the integrity and efficiency of various engine systems. In the centrifuge cover kit, this O-Ring Seal ensures a tight seal around the cover, preventing any leakage of fluids or contaminants that could compromise the centrifuge’s performance.

Within the full flow oil filter and lubricating oil filter systems, the O-Ring Seal plays a significant role in maintaining the seal between the filter elements and the housing. This ensures that oil flows through the filter media without bypassing, which is essential for effective filtration and the removal of contaminants from the lubricating oil.

In the lubricating oil filter head, the O-Ring Seal is positioned to create a secure connection between the filter head and the engine block or filter housing. This seal is vital for maintaining system pressure and ensuring that the lubricating oil is properly directed through the filtration process before returning to the engine.

The oil cooler repair kit also benefits from the use of the O-Ring Seal. Here, it ensures that the connections between the oil cooler components are sealed, preventing any oil leaks and maintaining the efficiency of the cooling process. This is particularly important in high-performance engines where maintaining optimal oil temperature is key to engine longevity and performance.

Overall, the part 3633001 O-Ring Seal is a fundamental component in these engine systems, ensuring that seals are maintained, contaminants are effectively filtered, and system pressures are preserved, all of which contribute to the overall efficiency and reliability of the engine.

Conclusion

The Cummins 3633001 O-Ring Seal is a vital component in maintaining the efficiency and reliability of commercial truck systems. Its precise design, durable material composition, and compatibility with various engine models make it an essential part for ensuring system integrity, preventing leaks, and maintaining optimal pressure conditions. Regular maintenance and proper installation are key to maximizing the performance and longevity of this Cummins part.

-

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill, 2018.

↩ -

Hu, Haoran, Rudy Smaling, and Simon Baseley. Heavy-Duty Wheeled Vehicles. SAE International, 2014.

↩ -

Dixon, John. Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.